Calculation method of inverse problem design of rotary mechanical vane

A technology of rotating machinery and calculation methods, applied in calculation, design optimization/simulation, special data processing applications, etc., can solve problems such as lack of very effective accuracy, and achieve the effect of clear thinking, high calculation efficiency, and good convergence stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with specific embodiments.

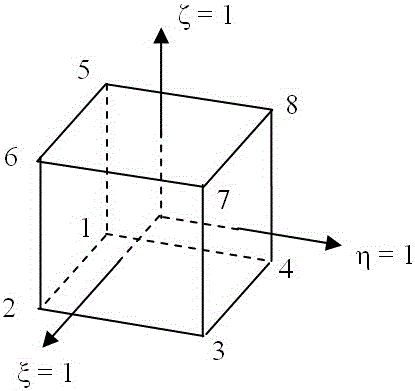

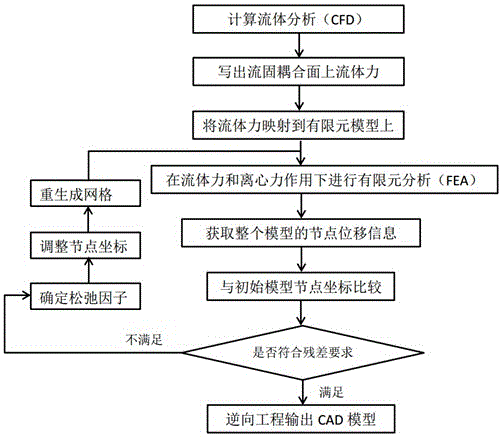

[0035] refer to Figure 1-2 , the calculation method for the inverse problem design of the rotating machinery blade proposed by the present invention, the specific operation process includes the following steps:

[0036] Step 1, input the model that needs anti-torsion design, establish the computational domain of computational fluid analysis (CFD), set boundary conditions, set residual conditions, and perform steady calculations to obtain the flow field distribution and pressure distribution around the blade at a stable moment;

[0037] Step 2, write the pressure data on the blade surface (fluid-solid coupling surface), the data format is divided into four columns, which are X coordinate value, Y coordinate value, Z coordinate value and pressure;

[0038] Step 3, input the model that needs reverse torsion design, load the pressure load in step 2, set the boundary condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com