Display device, backlight module and field emission light source device

A light source device and field emission technology, which is applied to lamp parts and other directions, can solve the problems of serious heating, poor thermal conductivity, and shortened service life of field emission lighting devices, and achieve the effects of low cost, solving serious heating, and enhancing thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

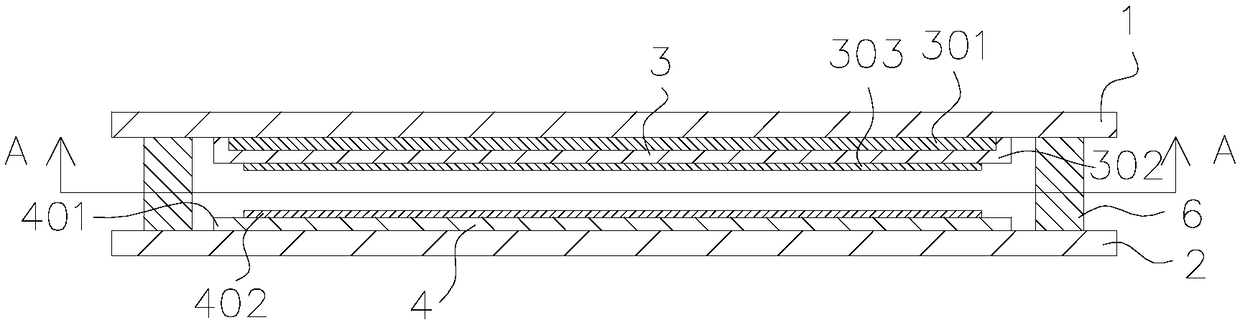

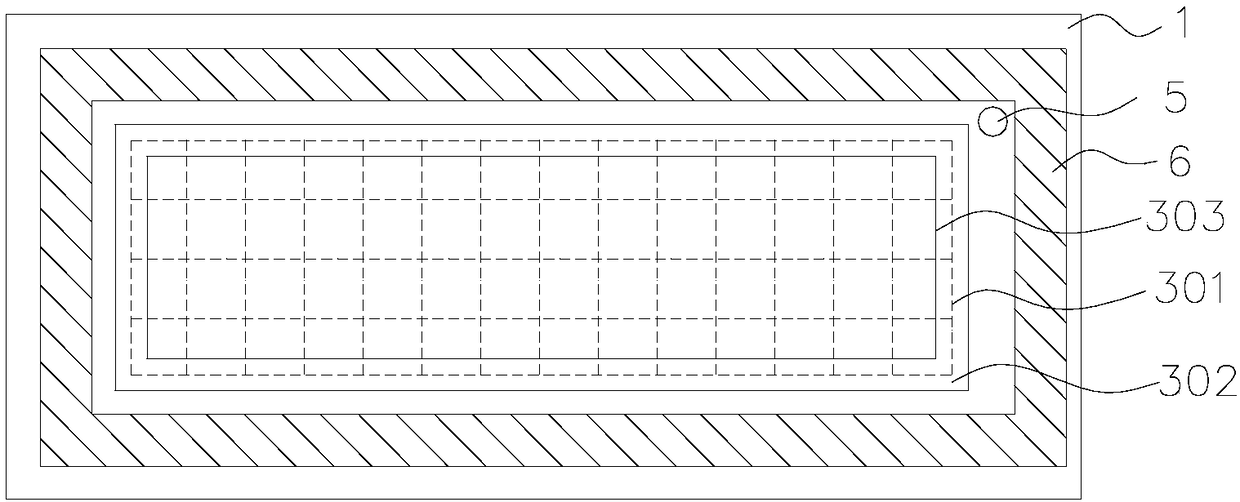

[0038] One of the specific implementation methods is as follows:

[0039]Make metal grid lines on the light emitting area on the white glass first. The physical vapor deposition process (PVD) is used to make the entire metal film. The metals are preferably Ti, Cu, W, Mo, Ag, Al, Au, Pt, etc., the target purity is >99.99%, and the film thickness is 10-100nm. Coat a layer of positive photoresist for TFT LCD on the metal film with a thickness of 1.5-5um. Using photolithography process, only the metal grid line pattern (pattern) in the light-emitting area is retained. The width of the metal line is 2-20um, accounting for less than the area of the light-emitting area. More than 5%.

[0040] In addition to the method of using positive photoresist, it is also possible to coat a layer of negative photoresist on the white glass (positive photoresist can also be used, the precision is slightly worse than negative photoresist), and the film thickness is 1.5-5um. After a photolithogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com