Energy Dispersive X-ray Fluorescence Analysis System

A technology of fluorescence analysis and energy dispersion, which is applied in the analysis of materials, material analysis by using wave/particle radiation, and measurement devices, etc., can solve the problems that it is difficult to ensure the safety of high-level radioactive solutions, the matrix effect cannot be corrected, and the texture of Se is brittle. The effect of compact structure, simple structure and short sample distance

Active Publication Date: 2010-11-10

CHINA INSTITUTE OF ATOMIC ENERGY

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since Se is added in the primary optical path, it can only correct instrument fluctuations, but cannot correct matrix effects

At the same time, Se is brittle and not easy to fix

In addition, the traditional sample box uses Mylar film as the bottom window of the sample tank, which is difficult to ensure the safety of high-level solution operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

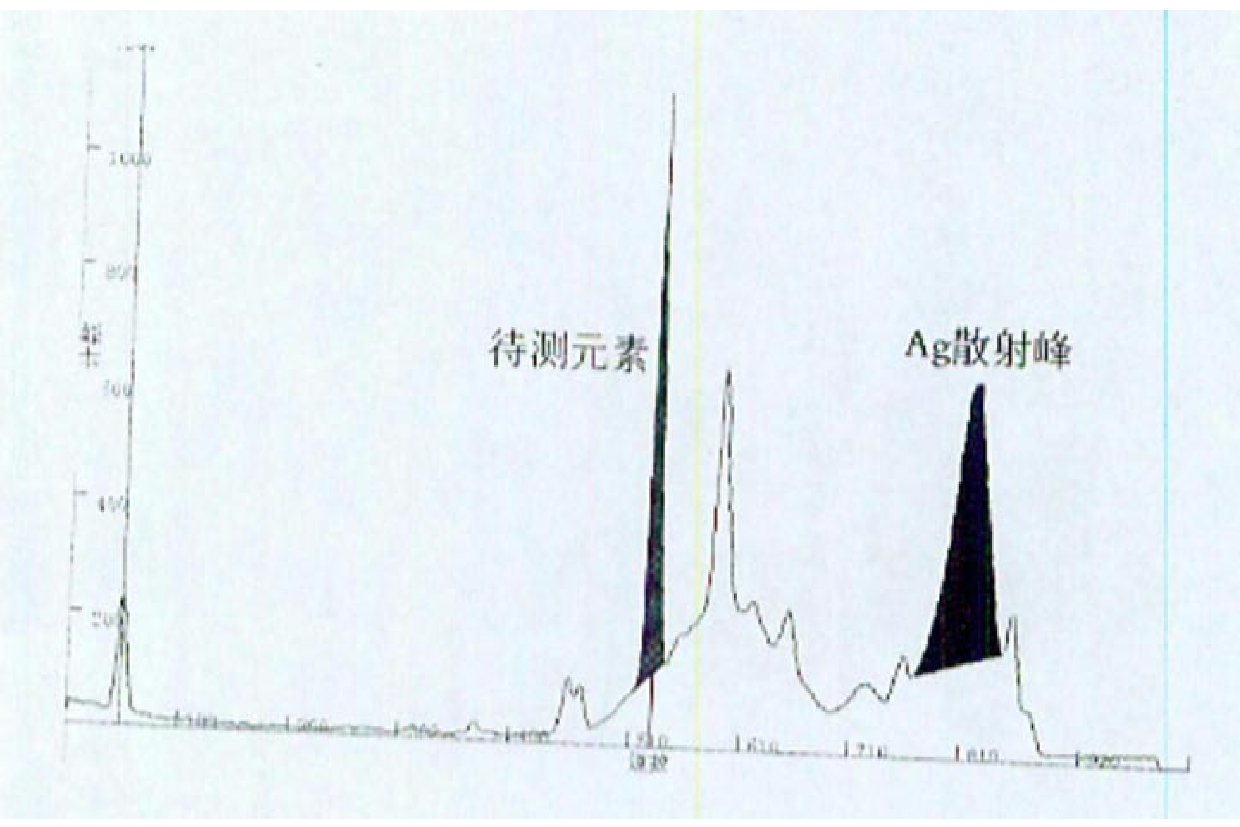

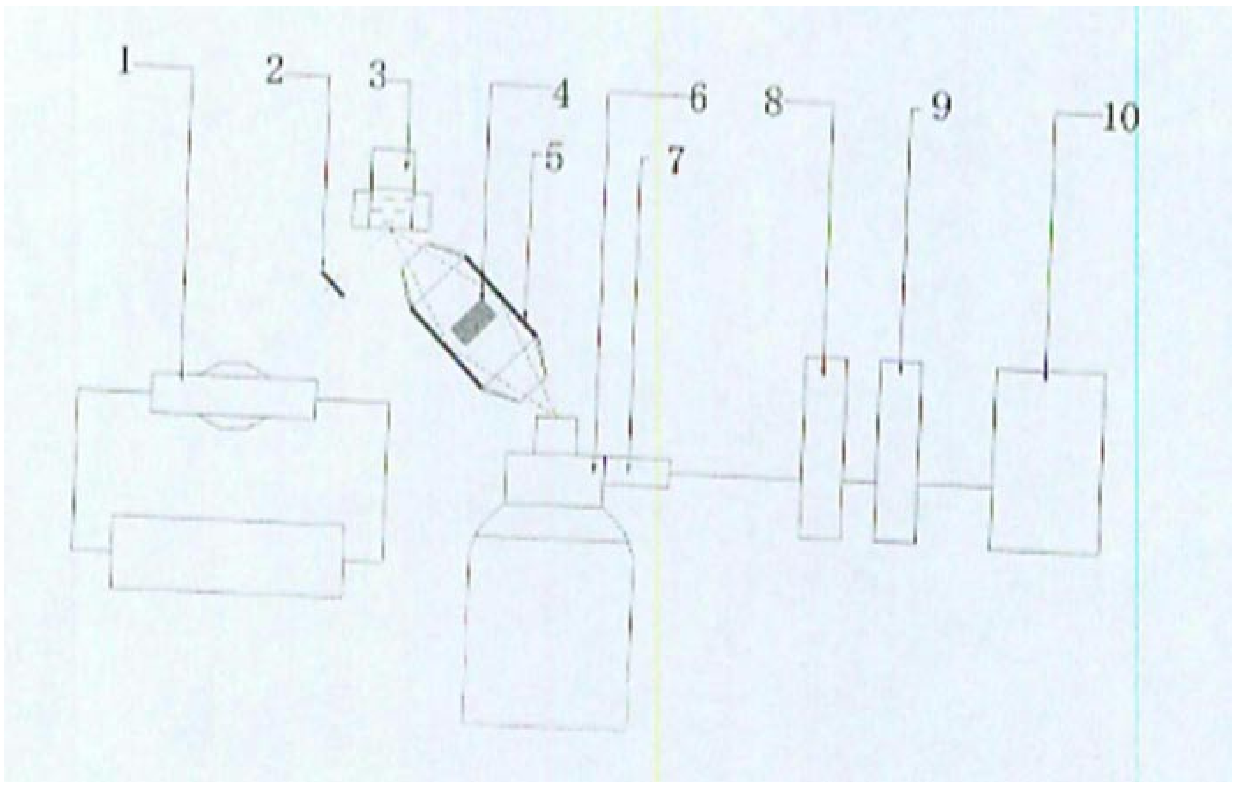

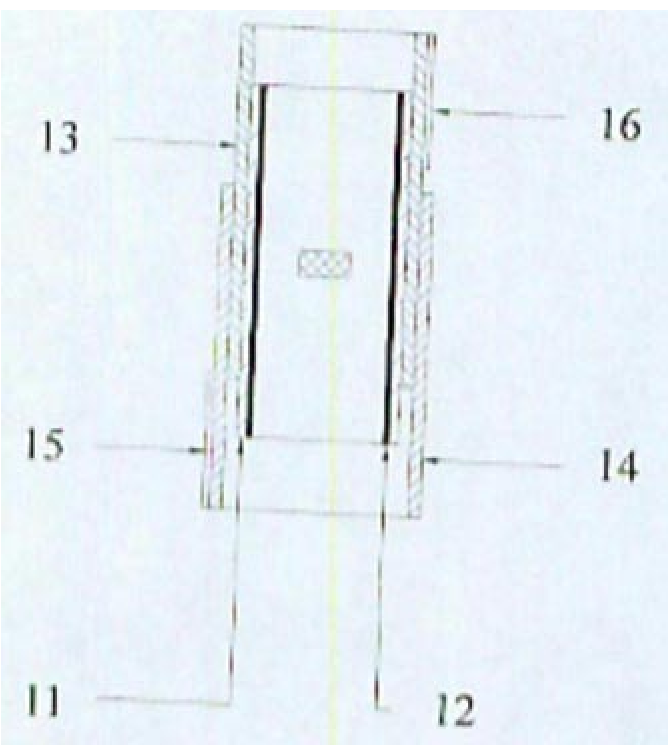

The invention belongs to the determination technology of elements in a radioactive environment, and specifically relates to a graphite crystal pre-diffraction energy dispersive X-ray fluorescence analysis system, which consists of an X-ray tube excitation system, a graphite crystal diffraction optical path, a Si(Li) detector multi-channel system, and a computer. Spectrum processing system, in which the X-ray tube excitation system is composed of X-ray tubes and corresponding circuits and shielding bodies; the graphite crystal diffraction optical path includes optical filters, sample boxes and graphite diffractometers, and graphite diffractometers are cylindrical graphite bodies. Place the shielding body, the energy dispersive X-ray fluorescence analysis system uses internal standard or scattering internal standard to correct the measured intensity; the X-ray tube excitation system uses a low-power X-ray generator of 150-350W; the shielding body in the graphite diffractometer is cylindrical . The system has a short distance from the focal spot to the sample and a compact structure; the shielding body in the graphite diffractometer has a simple structure, lower detection limits, and less sampling volume.

Description

Energy Dispersive X-ray Fluorescence Analysis System technical field The invention belongs to the determination technology of elements in a radioactive environment, and in particular relates to a graphite crystal pre-diffraction energy dispersive X-ray fluorescence analysis system. Background technique The average burnup depth of spent fuel elements in power reactors exceeds 3300MWd / t, and its radioactive intensity is dozens of times that of fuel elements in production reactors. In the advanced two-cycle reprocessing process for processing power reactor spent fuel components, the specific activity of 1AW waste liquid is as high as 10 12 ~10 13 Bq / L, therefore, the analysis of trace actinides and splinter elements in 1AW presents great technical difficulties. However, the content of uranium, neptunium and molybdenum in 1AW is related to the recovery rate of uranium, the direction of neptunium and the decontamination coefficient of lobes, so it must be analyzed. Therefore...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N23/223

Inventor 黄清良金立云吴继宗郑维明宋游刘桂娇

Owner CHINA INSTITUTE OF ATOMIC ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com