Indium antimonide infrared focal plane array detector chip and manufacturing method thereof

An indium antimonide infrared focus and detector chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as low reliability, achieve optimal reliability and stability, reduce strain, and improve reliability. Effect

Active Publication Date: 2013-05-15

CHINA AIR TO AIR MISSILE INST

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the problem of low reliability of the indium antimonide infrared focal plane array detector chip in the prior art, the present invention provides an indium antimonide infrared focal plane array detector chip with high reliability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

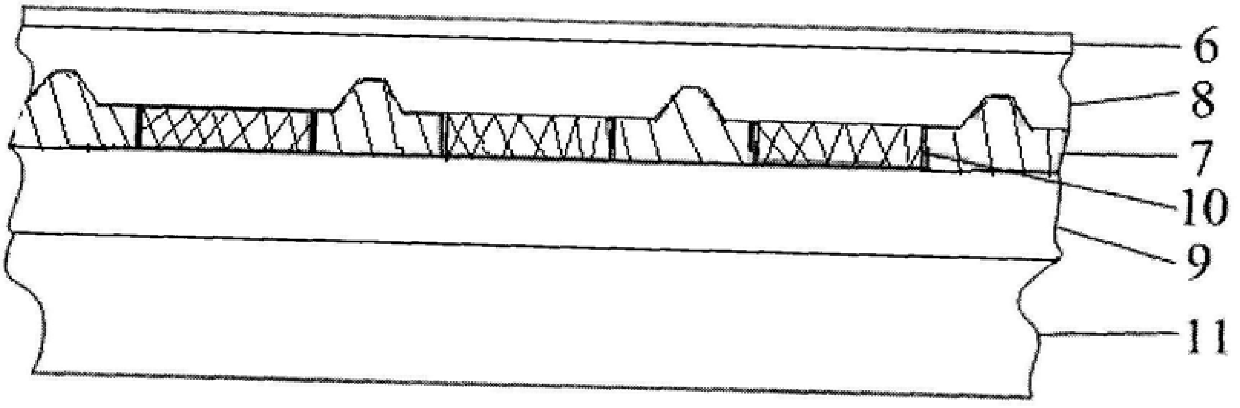

An indium antimonide infrared focal plane array detector chip, which includes an antireflection film [6], a low-temperature glue [7], an indium antimonide photosensitive array [8], a silicon readout circuit [9], and an indium column [10] , InSb substrate [11]. Wherein, the indium antimonide photosensitive array [8] is provided with an antireflection film [6] on the back, and an indium pillar [10] is provided on the front. The other end of the indium column [10] is connected to the silicon readout circuit [9], and the backside of the silicon readout circuit [9] is provided with an indium antimonide substrate [11], and the indium antimonide photosensitive array [8], the silicon A low-temperature glue [7] is arranged in the gap between the readout circuit [9] and the indium column [10]. The indium antimonide infrared focal plane array detector chip of the invention achieves thermal matching with the indium antimonide photosensitive array and the silicon readout circuit, reduces strain, and makes the indium antimonide infrared focal plane array detector have higher reliability. In addition, the invention provides a method for manufacturing the indium antimonide infrared focal plane array detector chip.

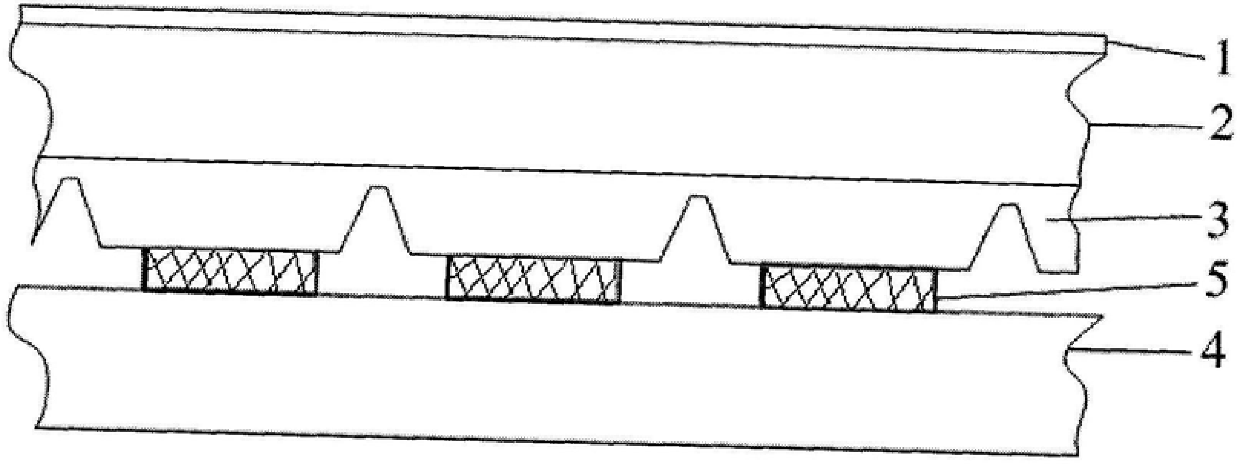

Description

Indium antimonide infrared focal plane array detector chip and manufacturing method thereof technical field The invention belongs to semiconductor photodetector manufacturing technology, and relates to an indium antimonide infrared focal plane array detector chip and a manufacturing method thereof. Background technique In the process of fabricating an InSb infrared focal plane array detector chip, structural design is a key process that determines the performance and reliability of the detector. The indium antimonide infrared focal plane array detector chip has to withstand the impact from normal temperature (300K) to liquid nitrogen temperature (77K) during testing and work. The thermal expansion coefficient of indium antimonide material is 5.04×10-6K, and the thermal expansion coefficient of silicon material The coefficient is 2.6×10-6K, and there is a large difference in the coefficient of thermal expansion between the two, so the stress caused by thermal mismatch is an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L31/101H01L31/18

Inventor 成彩晶吴伟付月秋曹光明张向锋李明华

Owner CHINA AIR TO AIR MISSILE INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com