Plateau hillside drip irrigation system

A hillside and plateau technology, applied in the field of plateau hillside drip irrigation system, can solve the problems of large slope, large temperature difference between day and night, and inapplicability, and achieve the effect of reducing waste and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

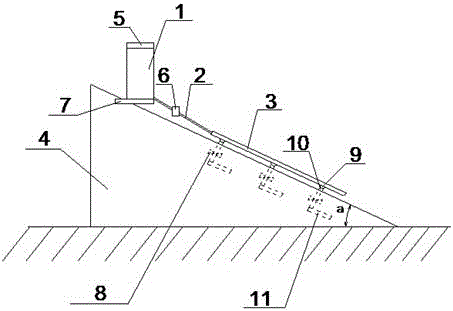

[0030] Such as figure 1 As shown, the plateau hillside drip irrigation system structure schematic diagram, the plateau hillside drip irrigation system includes a water storage tank 1, water delivery pipe 2, drip irrigation pipe 3, fixed plate 7, buried pipe 10 and drip irrigation branch pipe 11. Wherein the fixed plate 7 is horizontally fixed on the hillside 4, and the water storage tank 1 is fixed on the fixed plate 7. The water storage tank 1 is connected with the drip irrigation pipe 3 through the water delivery pipe 2, and the drip irrigation pipe 3 is erected on the soil surface 16. One end of the buried pipe 10 is connected to the drip irrigation pipe 3 , and the other end is vertically connected to the drip irrigation branch pipe 11 . Both the drip irrigation pipe 3 and the drip irrigation branch pipe 11 are provided with a drip irrigation port 12 . The buried pipe 10 communicates with the drip irrigation pipe 3 through the movable part 9 . The drip irrigation pipe 3 ...

Embodiment 2

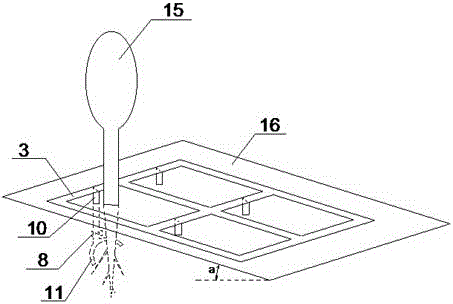

[0034] Such as figure 2 As shown, another plateau hillside drip irrigation system structure schematic diagram, including drip irrigation pipe 3, buried pipe 10, flow valve 8, drip irrigation branch pipe 11. The drip irrigation pipe 3 is erected on the soil surface 16 and is located on the periphery of the trees 15 . One end of the buried pipe 10 is connected with the drip irrigation pipe 3 , and the other end is inserted into the soil surface 16 and vertically connected with the drip irrigation branch pipe 11 . The drip irrigation branch pipe 11 is arranged on the periphery of the main root of the tree 15 . The drip irrigation branch pipe 11 is a semicircular arc, and the connection point between the drip irrigation branch pipe 11 and the buried pipe 10 is located on the symmetry axis of the semicircular arc. The slope of hillside 4 is a, and a is 22°

[0035] When in use, the drip irrigation branch pipe 11 is a semi-circular arc, and the water from the drip irrigation inf...

Embodiment 3

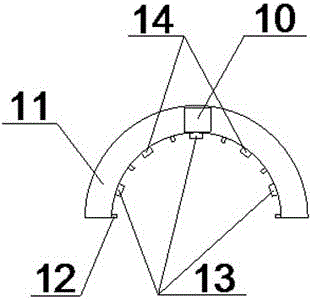

[0037] Such as image 3 As shown in the schematic diagram of the structure of the drip irrigation branch pipe, the drip irrigation branch pipe 11 is a semi-circular arc, and the connection point between the drip irrigation branch pipe 11 and the buried pipe 10 is located on the symmetry axis of the semi-circular arc. The inner arc of the drip irrigation branch pipe 11 is evenly distributed with magnetization ports 13 and heating ports 14, and the magnetization ports 13 and heating ports 14 are arranged alternately. The drip irrigation port 12 on the drip irrigation branch pipe 11 is located on the inner arc of the drip irrigation branch pipe 11 , and is located between the magnetization port 13 and the heating port 14 .

[0038] During use, water penetrates into the soil through the drip irrigation port 12 on the drip irrigation branch pipe 11, the magnetization port 13 can promote the root hair development of the tree 15 through the effect of the magnetic field, and the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com