Production process of farm chemical emulsion in water

A production process and water-emulsion technology, applied in the agricultural field, can solve problems such as low stability and complicated process, and achieve the effects of non-layered stability, broad market prospects, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

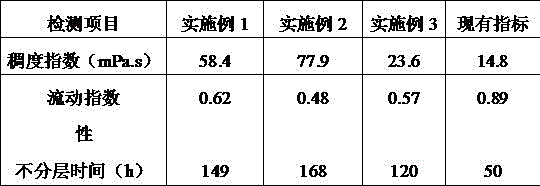

Examples

Embodiment 1

[0025] A kind of production technology of pesticide emulsion in water, comprises the steps:

[0026] (1) Raw material preparation

[0027] First prepare the emulsifier monomer agricultural milk 500, Pol, Tween-20 and JFC of producing pesticide water emulsion, the ratio of described agricultural milk 500, Pol, Tween-20 and JFC is 3:2:1:1;

[0028] (2) Preparation of oil phase

[0029] Add spirodiclofen raw powder, dispersant and emulsifier monomer into the oil phase tank, and then stir for 10 minutes to form the oil phase. The dispersant is KN-D30;

[0030] (3) Water phase preparation

[0031] Add water, antifreeze, pH regulator, thickener and defoamer to the water phase preparation tank, and start stirring at the same time to form a water phase, and the stirring time is 10 minutes;

[0032] (4) Oil phase and water phase are mixed

[0033] Add the oil phase to the high-speed shear kettle, then open the high-speed shear kettle, and then gradually add the water phase to stir ...

Embodiment 2

[0039] A kind of production technology of pesticide emulsion in water, comprises the steps:

[0040] (1) Raw material preparation

[0041] First prepare the emulsifier monomer agricultural milk 500, Pol, Tween-20 and JFC of producing pesticide water emulsion, the ratio of described agricultural milk 500, Pol, Tween-20 and JFC is 4:3:1.5:1.5;

[0042] (2) Preparation of oil phase

[0043] Add spirodiclofen raw powder, dispersant and emulsifier monomer into the oil phase kettle, and then stir for 15 minutes to form an oil phase. The dispersant is KN-D30;

[0044] (3) Water phase preparation

[0045] Add water, antifreeze, pH regulator, thickener and defoamer to the water phase preparation tank, and start stirring at the same time to form a water phase, and the stirring time is 20 minutes;

[0046] (4) Oil phase and water phase are mixed

[0047] Add the oil phase to the high-speed shear kettle, then open the high-speed shear kettle, and then gradually add the water phase to ...

Embodiment 3

[0053] A kind of production technology of pesticide emulsion in water, comprises the steps:

[0054] (1) Raw material preparation

[0055] First prepare the emulsifier monomer agricultural milk 500, Pol, Tween-20 and JFC of producing pesticide water emulsion, the ratio of described agricultural milk 500, Pol, Tween-20 and JFC is 5:4:2:2;

[0056] (2) Preparation of oil phase

[0057] Add the spirodiclofen raw powder, dispersant and emulsifier monomer into the oil phase tank, and then stir for 20 minutes to form the oil phase. The dispersant is KN-D30;

[0058] (3) Water phase preparation

[0059] Add water, antifreeze, pH regulator, thickener and defoamer to the water phase preparation tank, and start stirring at the same time to form a water phase, and the stirring time is 30 minutes;

[0060] (4) Oil phase and water phase are mixed

[0061] Add the oil phase to the high-speed shear kettle, then open the high-speed shear kettle, and then gradually add the water phase to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com