Emulsion type sausage containing enzymatic modified soybean protein isolate and preparation method thereof

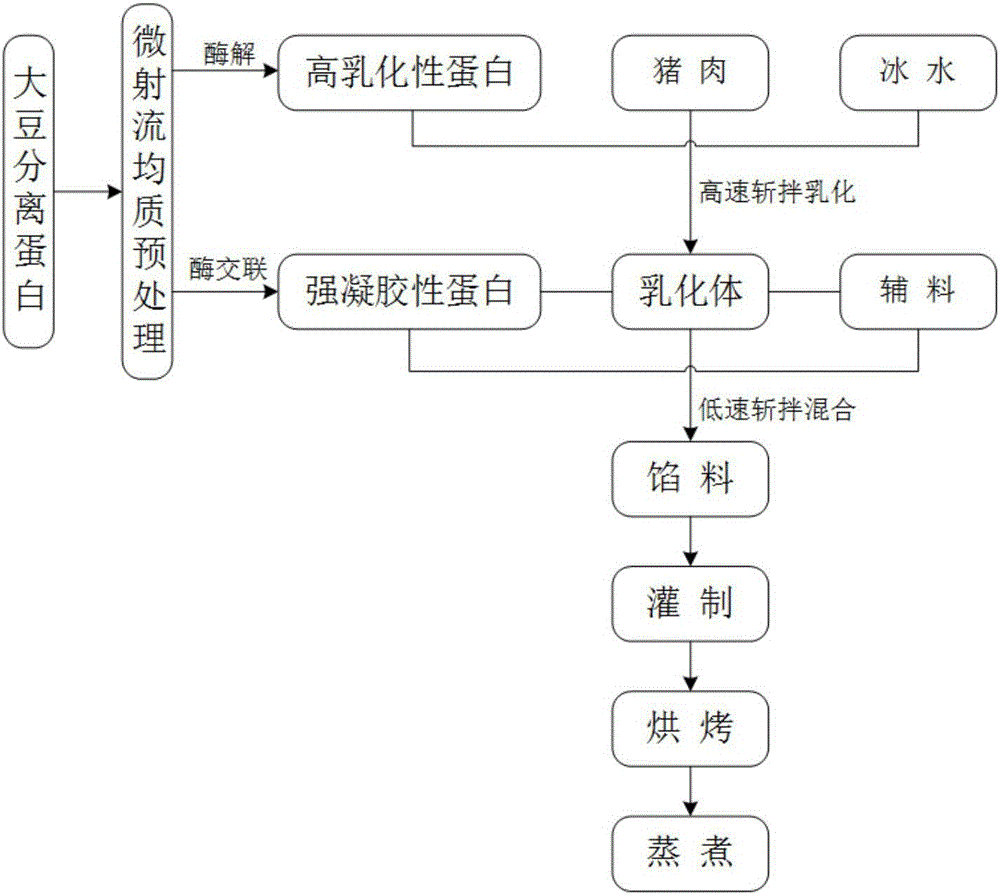

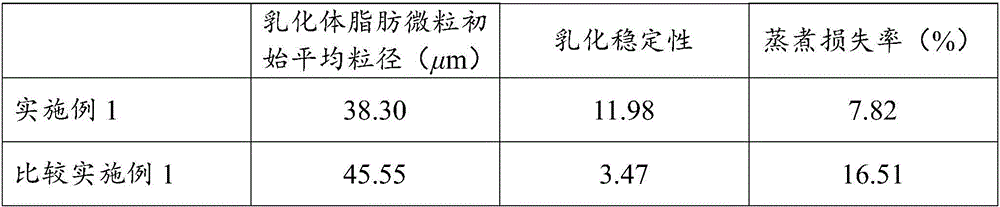

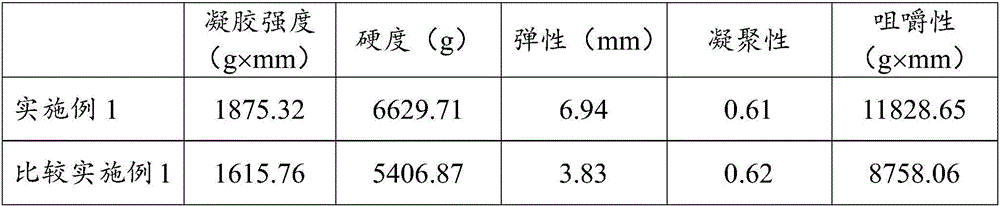

A technology for soybean protein isolate and emulsified sausage, which is applied to the field of emulsified sausage containing enzymatically modified soybean protein isolate and its preparation, and can solve the problems of adverse effects on the texture properties of emulsified sausage gels, adverse effects on emulsification stability of emulsified sausages and the like , to achieve the effect of improving nutritional structure and overall quality, reducing cooking loss rate, and improving emulsification stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Select 250g of fresh lean pork meat and 100g of pig back fat that have passed the sanitary supervision and quarantine, remove the broken bones, tendons, tendons and connective tissue membranes from the lean meat, and cut the lean pork and pig back fat into 1cm 3 About small pieces, mix 6 grams of salt with pork, marinate at 4°C for 16 hours, and then mince with a meat grinder. Mix 25g of high emulsifying enzymatic soy protein isolate, 80g of water, and 20g of ice in a chopping machine, add minced pork, chop and mix at high speed for 6 minutes (cutting speed 3000rpm), and keep emulsification at any time during the chopping process Body temperature ≤ 10 ℃. Then add 30g strong gelling enzyme cross-linked soy protein isolate, 3g sodium tripolyphosphate and 2g sodium pyrophosphate, chop and mix at low speed for 2min (cut and mix speed 600rpm), then add 100g cornstarch, 15g monosodium glutamate, 5g white pepper Flour, 0.3g isoascorbic acid, 80g water and 20g ice, chop and mi...

Embodiment 2

[0053] Select 500g of fresh lean pork meat and 300g of pig back fat that have passed the sanitary supervision and quarantine, remove the broken bones, tendons, tendons and connective tissue membranes from the lean meat, and cut the lean pork and pig back fat into 1cm 3 About small pieces, mix 12 grams of salt with pork evenly, marinate at 4°C for 24 hours, and then mince them with a meat grinder. Mix 55g of highly emulsifying enzymatic soy protein isolate, 160g of water, and 40g of ice in a chopping machine, add minced pork, chop and mix at high speed for 8 minutes (cutting speed 3200rpm), and keep emulsification at any time during the chopping process Body temperature ≤ 10 ℃. Then add 60g strong gelling enzyme cross-linked soy protein isolate, 6g sodium tripolyphosphate and 4g sodium pyrophosphate, chop and mix at a low speed for 3min (cut and mix speed 600rpm), then add 180g cornstarch, 25g monosodium glutamate, 12g white pepper Flour, 0.6g isoascorbic acid, 160g water and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com