A method and device for intermittently preparing high-concentration ozone water

An ozone water, high concentration technology, applied in mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of restricting the application of high concentration ozone water, low solubility, etc., to achieve low equipment cost, high concentration, easy to achieve Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

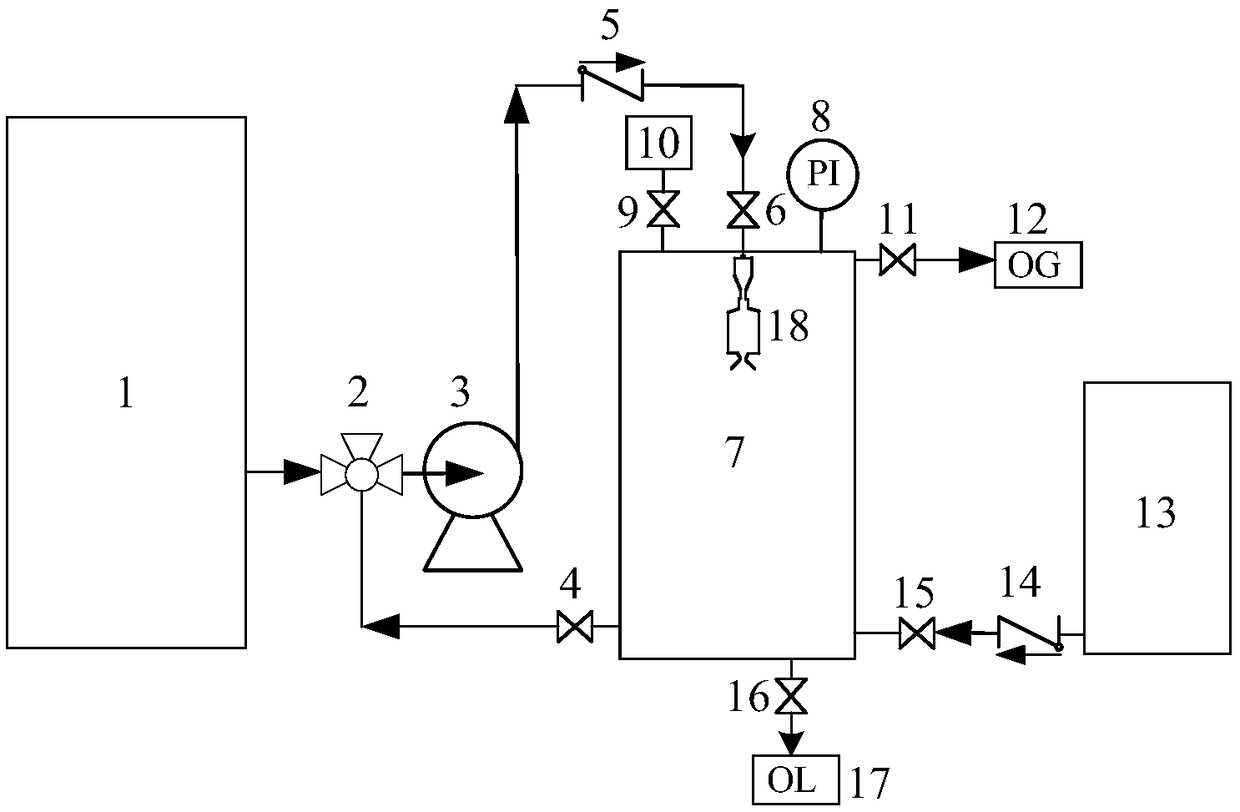

[0044] In this embodiment, high-concentration ozone water is prepared by dissolving ozone gas under 1 atmospheric pressure.

[0045] Install a three-way valve at the inlet of the booster pump, and connect the three-way valve with the outlet valve on the water storage tank and the ozone water generation tank. By adjusting the three-way valve, the booster pump inlet can be placed between the water storage tank and the ozone water generation tank. to switch. A water inlet check valve is installed at the outlet of the booster pump, and a water inlet valve is installed on the ozone water generating tank. The water inlet check valve and the water inlet valve are connected to prevent the gas in the tank from flowing backward from the water inlet. Install a variable-diameter nozzle in the ozone water generating tank and connect it with the water inlet valve on the tank. The volume of the ozone water generation tank is 10L.

[0046] Install a pressure vacuum gauge on the ozone water ...

Embodiment 2

[0052] In this embodiment, aiming at ozone gas under 1 atmospheric pressure, the water filling pressure is changed to dissolve and prepare high-concentration ozone water.

[0053] Install a three-way valve at the inlet of the booster pump, and connect the three-way valve with the outlet valve on the water storage tank and the ozone water generation tank. By adjusting the three-way valve, the booster pump inlet can be placed between the water storage tank and the ozone water generation tank. to switch. A water inlet check valve is installed at the outlet of the booster pump, and a water inlet valve is installed on the ozone water generating tank. The water inlet check valve and the water inlet valve are connected to prevent the gas in the tank from flowing backward from the water inlet. Install a variable-diameter nozzle in the ozone water generating tank and connect it with the water inlet valve on the tank. The volume of the ozone water generating tank is 40L.

[0054] Inst...

Embodiment 3

[0060] In this embodiment, high-concentration ozone water is prepared by dissolving ozone gas under 2 atmospheres.

[0061]Install a three-way valve at the inlet of the booster pump, and connect the three-way valve with the outlet valve on the water storage tank and the ozone water generation tank. By adjusting the three-way valve, the booster pump inlet can be placed between the water storage tank and the ozone water generation tank. to switch. A water inlet check valve is installed at the outlet of the booster pump, and a water inlet valve is installed on the ozone water generating tank. The water inlet check valve and the water inlet valve are connected to prevent the gas in the tank from flowing backward from the water inlet. Install a variable-diameter nozzle in the ozone water generating tank and connect it with the water inlet valve on the tank. The volume of the ozone water generation tank is 80L.

[0062] Install a pressure vacuum gauge on the ozone water generating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com