Wall-climbing air-free robot which works on the planking of the ship and the operational method of the wall-climbing air-free robot

A robot and drag coating technology, applied in the direction of manipulators, spraying devices, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure of the present invention will be further described below with reference to the accompanying drawings.

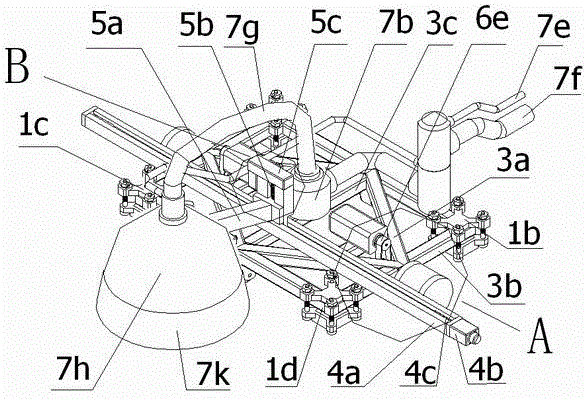

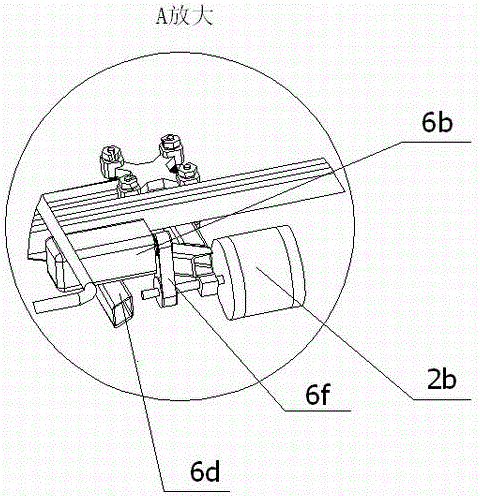

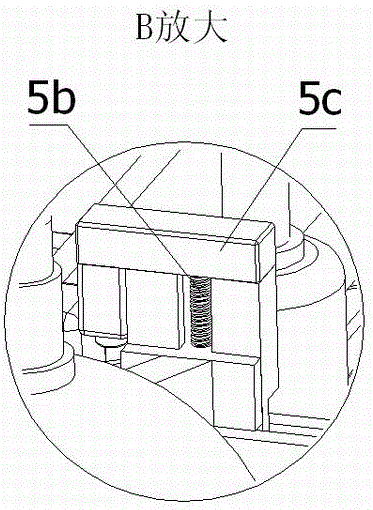

[0020] figure 1 , 2 , 3, 4, 5, 6, 7, and 8 show the structural diagram of the wall-climbing drag-painting robot for the ship's outer plate. The device mainly includes a diamond-shaped main frame, a magnetic adjustable device, a driving mechanism, a nozzle sweeping and protection device, a feeding pipe system, and a paint mist recovery pipe system.

[0021] The diamond-shaped carrying main frame is embedded and connected in the square adsorption device carrying frame 3b by the diamond-shaped strength frame 3a, and the parts are composed of square steel to carry various key components; Arranged at the four corners of the frame 3b of the square adsorption device to evenly disperse the adsorption force, the robot body is adsorbed on the surface of the steel ship's outer plate, and a strong adsorption force is provided to ensure that the robot works on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com