Sucker height automatic control method for sucker type clamps of manipulator

A technology of manipulators and suction cups, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problem of non-adjustable suction cup height, achieve significant economic benefits, reduce manufacturing costs, and increase flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

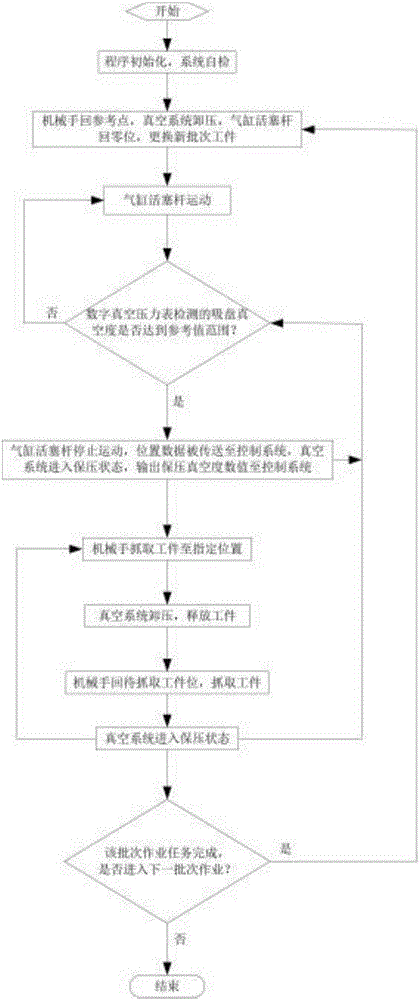

[0018] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, a suction cup height automatic control method for a manipulator suction cup fixture includes the following control steps: 1) Initialize the system program, and self-check the system; 2) Return the manipulator to the reference point, depressurize the vacuum system, and return the cylinder piston rod to zero position , to place a new batch of workpieces; 3) The cylinder piston rod moves to drive the suction cup to move to the workpiece adsorption surface, the digital vacuum pressure gauge detects that the vacuum degree of the suction cup reaches the reference value range, the cylinder piston rod stops moving, and transmits the position data to the control system, The vacuum system enters the pressure-holding state, and transmits the pressure-holding vacuum value to the control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com