Water purification machine system and control method for controlling system

A control method and technology of water purifiers, which are applied in the direction of water treatment parameter control, flow control of electric devices, flow control, etc., can solve problems such as waste of water, low recovery rate, and reduced service life of reverse osmosis membranes, so as to improve the system Effect of recovery rate, reduction of wastewater discharge, and reduction of fouling risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described below based on examples, but the present invention is not limited to these examples.

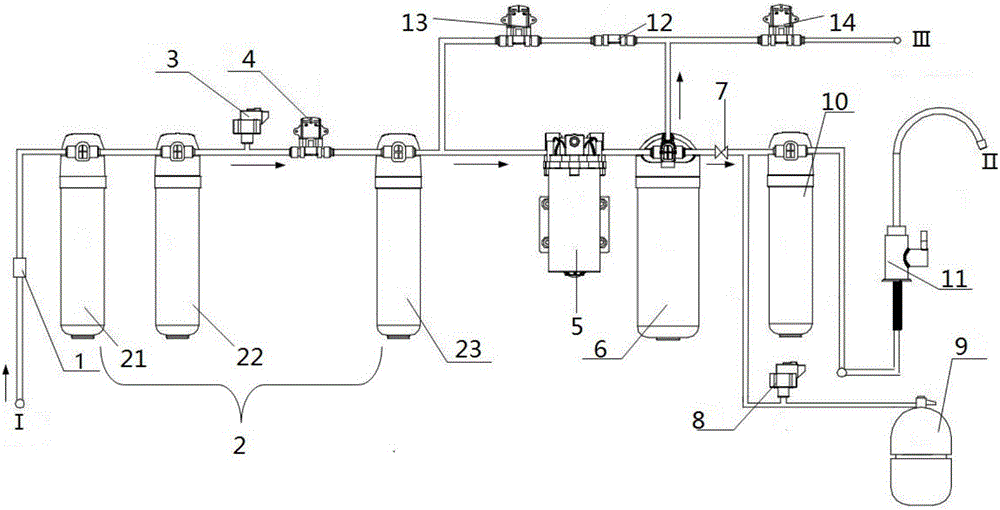

[0025] Such as figure 1 As shown, the present invention provides a water purifier system, including a raw water outlet I, a first filter element 6, a purified water outlet II, and a concentrated water outlet III. The raw water enters from the raw water inlet I and flows through the first filter element 6 to be separated into Purified water and concentrated water. The purified water can be discharged from the purified water outlet II, and the concentrated water can be discharged from the concentrated water outlet III. The water purifier system also includes a concentrated water return branch, which is suitable for returning the concentrated water to Upstream of the first filter element 6. The invention adds concentrated water backflow branch, improves raw water utilization rate, reduces concentrated water discharge, and improves system recovery rate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com