An outdoor high-hardness wear-resistant finish material and its preparation method

A coating material, high hardness technology, applied in the field of coatings, can solve the problems of poor acid and alkali resistance, oil resistance, easy cracking, etc., to achieve the effect of reducing construction costs, reducing maintenance costs, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] A method for preparing an outdoor high-hardness wear-resistant finish material, comprising the following steps in sequence:

[0032] S1: Prepare component A, including the following sub-steps in sequence:

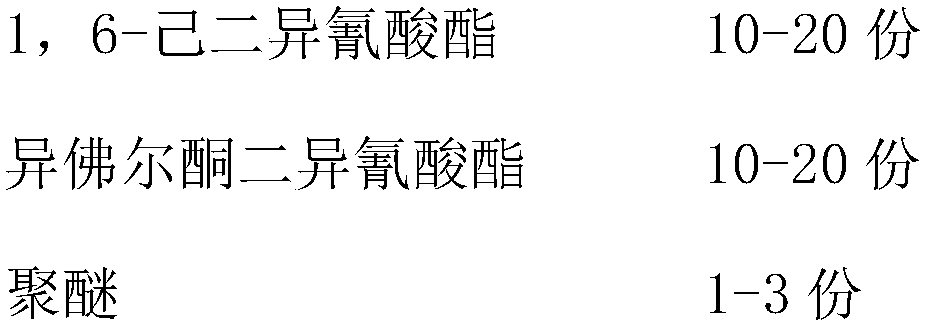

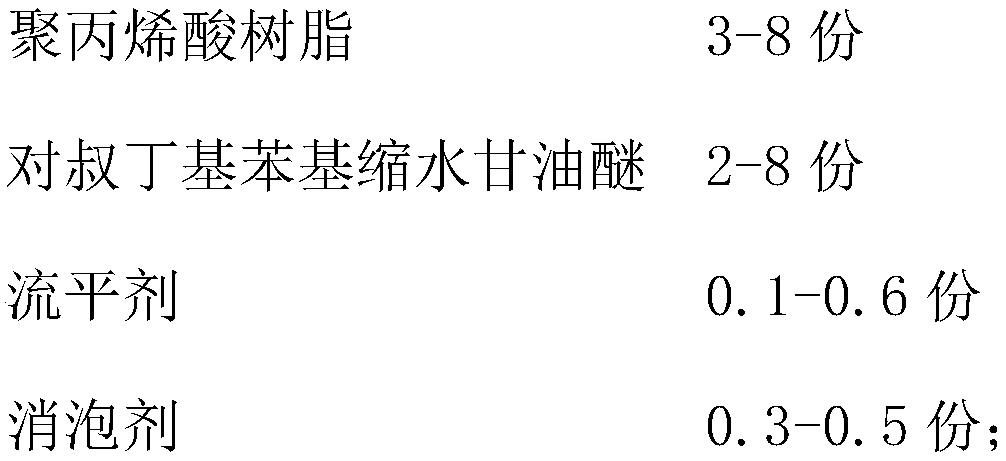

[0033] 1) Add 10-20 parts of 1,6-hexamethylene diisocyanate and 10-20 parts of isophorone diisocyanate into the first dispersion container, and disperse for 30-40 minutes at the speed of 800-1000r / min;

[0034] 2) Adjust the speed of the disperser to 1200-1800r / min, add 1-3 parts of polyether, 3-8 parts of polyacrylic resin, 2-8 parts of p-tert-butylphenyl glycidyl ether while dispersing, and disperse for 20-30 minute;

[0035] 3) Adjust the speed of the disperser to 1000-1200r / min, add 0.1-0.6 parts of leveling agent and 0.3-0.5 parts of defoamer in turn while dispersing, and disperse for 18-22 minutes until mixed evenly;

[0036] S2: Prepare component B: Add 5-10 parts of hydroxyl-containing organic fluorine resin and 5-11 parts of hydroxyl-containing silicone re...

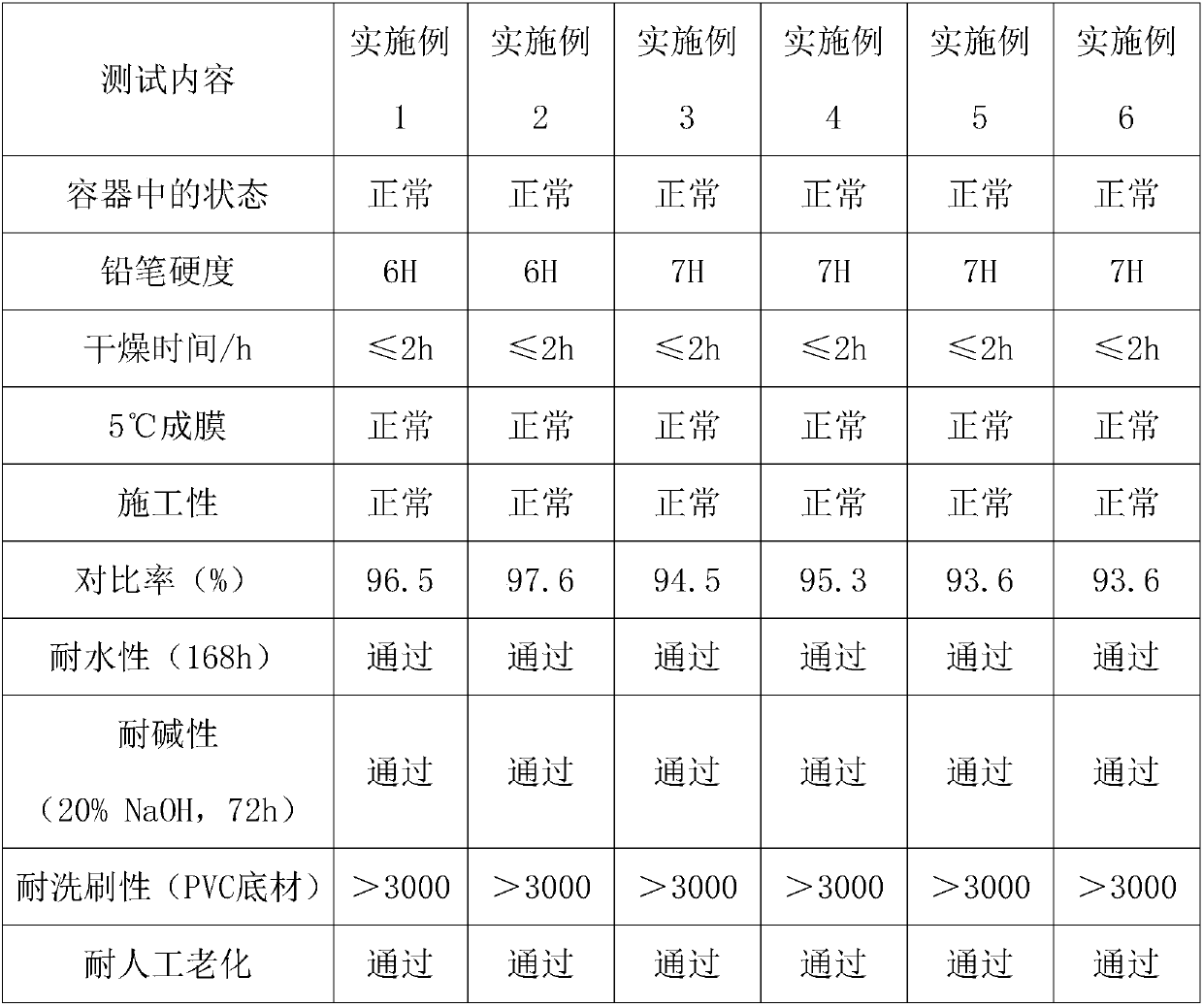

Embodiment 1

[0041] A method for preparing an outdoor high-hardness wear-resistant finish material, comprising the following steps in sequence:

[0042] S1: Prepare component A, including the following sub-steps in sequence:

[0043] 1) Add 15 parts of 1,6-hexamethylene diisocyanate and 15 parts of isophorone diisocyanate into the first dispersion container, and disperse for 35 minutes at a speed of 900r / min;

[0044] 2) Adjust the speed of the disperser to 1500r / min, add 2 parts of polyether, 5.5 parts of polyacrylic resin, and 5 parts of p-tert-butylphenyl glycidyl ether while dispersing, and disperse for 25 minutes;

[0045] 3) Adjust the speed of the disperser to 1100r / min, add 0.35 parts of leveling agent and 0.4 parts of defoamer in turn while dispersing, and disperse for 20 minutes until mixed evenly;

[0046] S2: Preparation of component B: add 8 parts of hydroxyl-containing organic fluorine resin and 8 parts of hydroxyl-containing silicone resin to the second dispersion vessel, a...

Embodiment 2

[0049] A method for preparing an outdoor high-hardness wear-resistant finish material, comprising the following steps in sequence:

[0050] S1: Prepare component A, including the following sub-steps in sequence:

[0051]1) Add 18 parts of 1,6-hexamethylene diisocyanate and 18 parts of isophorone diisocyanate into the first dispersion container, and disperse for 36 minutes at the speed of 950r / min;

[0052] 2) Adjust the speed of the disperser to 1600r / min, add 2.2 parts of polyether, 6 parts of polyacrylic resin, and 6 parts of p-tert-butylphenyl glycidyl ether while dispersing, and disperse for 26 minutes;

[0053] 3) Adjust the speed of the disperser to 1150r / min, add 0.35 parts of leveling agent and 0.35 parts of defoamer in sequence while dispersing, and disperse for 21 minutes until mixed evenly;

[0054] S2: Preparation of component B: add 8 parts of hydroxyl-containing organic fluorine resin and 9 parts of hydroxyl-containing silicone resin to the second dispersion con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com