A two-degree-of-freedom halbach array deflection Lorentz force magnetic bearing

A Lorentz force-magnetism and degree-of-freedom technology, applied in the direction of bearings, shafts and bearings, shafts, etc., can solve the problems of small torsional torque of magnetic bearing bearing capacity, reduced magnetic bearing control accuracy, low magnetic field strength, etc. Bearing capacity and support stiffness, reduce suspension power consumption, and enhance the effect of air gap magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

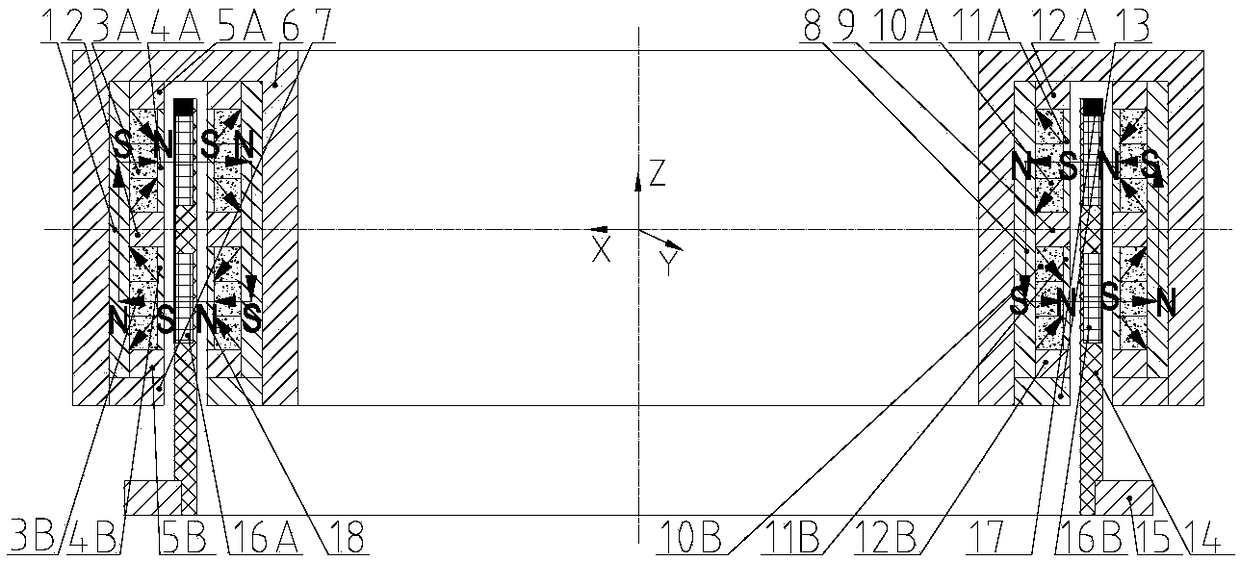

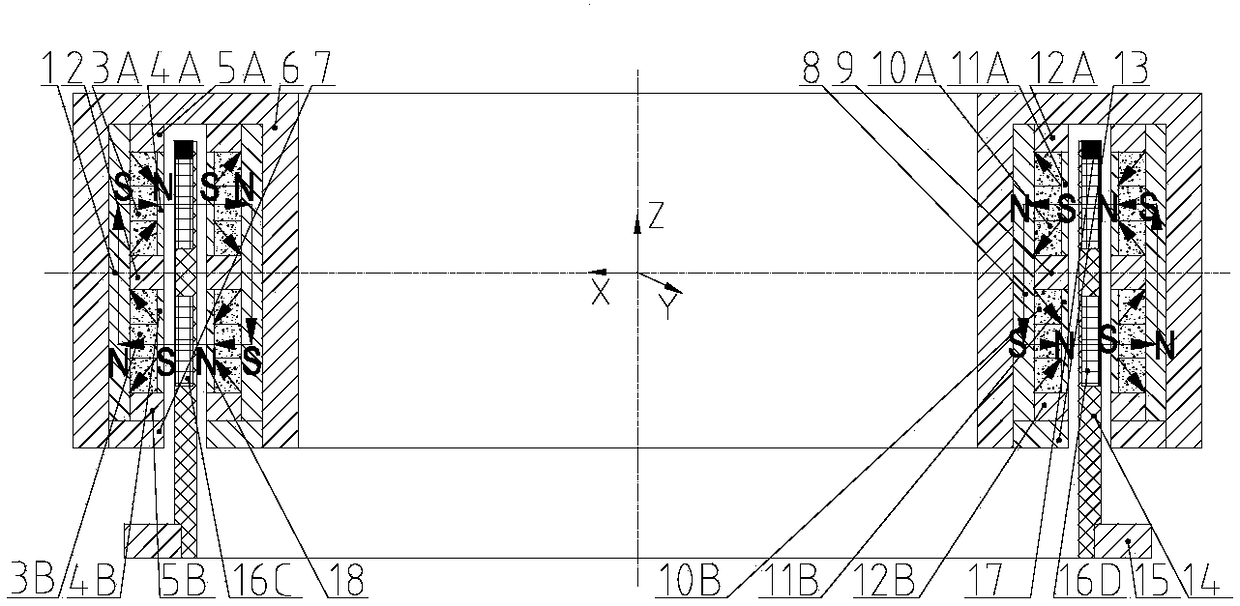

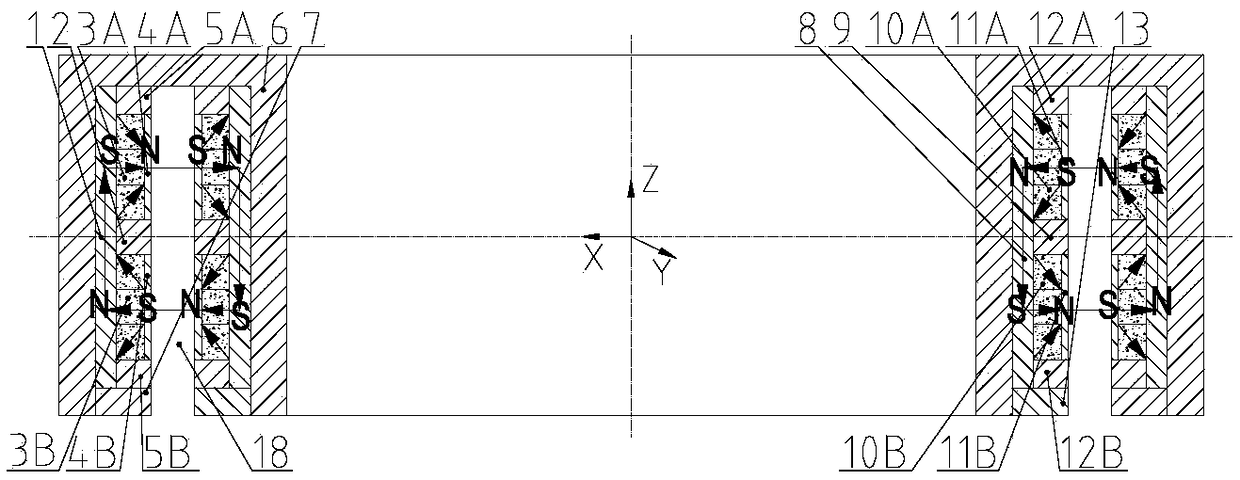

[0019] The two-degree-of-freedom Halbach array deflection Lorentz force magnetic bearing of the present invention, its preferred embodiment is:

[0020]It is mainly composed of rotor system and stator system. The rotor system mainly includes: outer magnetic sleeve, outer magnetic ring, outer upper Halbach array magnetic steel, outer lower Halbach array magnetic steel, outer upper paramagnetic sleeve, outer lower paramagnetic sleeve, Outer upper magnetic steel lock nut, outer lower magnetic steel lock nut, turntable, outer component lock nut, inner magnetic sleeve, inner magnetic ring, inner upper Halbach array magnet, inner lower Halbach array magnet, inner upper paramagnetic sleeve , inner and lower paramagnetic sleeve, inner upper magnetic steel lock nut, inner lower magnetic steel lock nut and inner component lock nut; the stator system mainly includes: stator frame, aluminum substrate, left winding, right winding, front winding, rear winding and ring Oxygen resin glue; the...

specific Embodiment

[0027] Such as figure 1 , 2As shown, a two-degree-of-freedom Halbach array deflection Lorentz force magnetic bearing is mainly composed of a rotor system and a stator system. It is characterized in that the rotor system mainly includes: an outer magnetic sleeve 1, an outer magnetic ring 2, an outer upper Halbach array magnetic steel 3A, outer lower Halbach array magnetic steel 3B, outer upper paramagnetic sleeve 4A, outer lower paramagnetic sleeve 4B, outer upper magnetic steel lock nut 5A, outer lower magnetic steel lock nut 5B, turntable 6, outer component lock Female 7, inner magnetic sleeve 8, inner magnetic ring 9, inner upper Halbach array magnet 10A, inner lower Halbach array magnet 10B, inner upper paramagnetic sleeve 11A, inner lower paramagnetic sleeve 11B, inner upper magnetic steel lock Mother 12A, inner lower magnetic steel lock mother 12B and inner component lock mother 13; the stator system mainly includes: stator frame 14, aluminum substrate 15, left winding 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com