Standard mix based on rapid detection of ewe milk composition and preparation process thereof

A technology of mixing standard products and preparation process, applied in the field of food science, can solve the problems of non-appearance of goat milk ingredients, inaccurate detection of goat milk, etc., and achieve the effect of accurate calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1: Preparation of Goat Milk Components Mixed Standards by Pseudo-Horizontal Uniform Design Method

[0054] 1) Take out 6 bottles of milk (about 1300mL) from the freezer, wash them twice with cold water, then thaw them at room temperature, then filter them into a large beaker with double-layer gauze to remove foreign matter and other impurities;

[0055] 2) Divide the filtered goat milk into centrifuge tubes, the volume of which is not more than 2 / 3 of the volume of the centrifuge tube, and then balance it with a tray balance;

[0056] 3) Put the balanced centrifuge tubes in a refrigerated centrifuge, centrifuge at 4°C, 5500r / min for 15min, repeat twice, carry out refrigerated centrifugation, and use a key to dig out the frozen fat in the upper layer, and put the obtained fat in a beaker , seal the mouth of the beaker with plastic wrap, and put it in a 4°C refrigerator for later use;

[0057] 4) Stir the degreased skim milk evenly with a glass rod, filter it int...

Embodiment 2

[0064] Example 2: Preparation of Goat Milk Ingredients Mixed Standards by Equal Level Uniform Design Method

[0065] In order to better determine the method of uniform design, Example 2 adopts the equal-level uniform design method to prepare mixed standards. In this experiment, the lactose was reduced by the gradient difference, set to 3.4%, 3.6%, 3.8%, 4.0%, 4.2%, 4.4%, 4.6%, 4.8%, 5.0%, 5.2%, 10 levels of gradients, taking equal levels The uniform design method, as shown in Table 3. When carrying out sample configuration in this experiment, refer to Table 3 to configure, and the rest of the steps are the same as in Example 1, and the specific configuration table is as shown in Table 4:

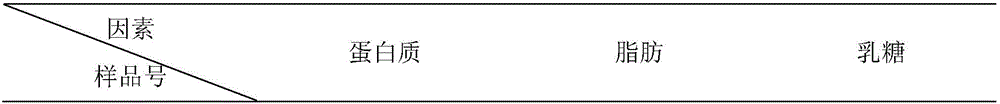

[0066] Table 3 Uniform design table of equal levels (g / 100g)

[0067]

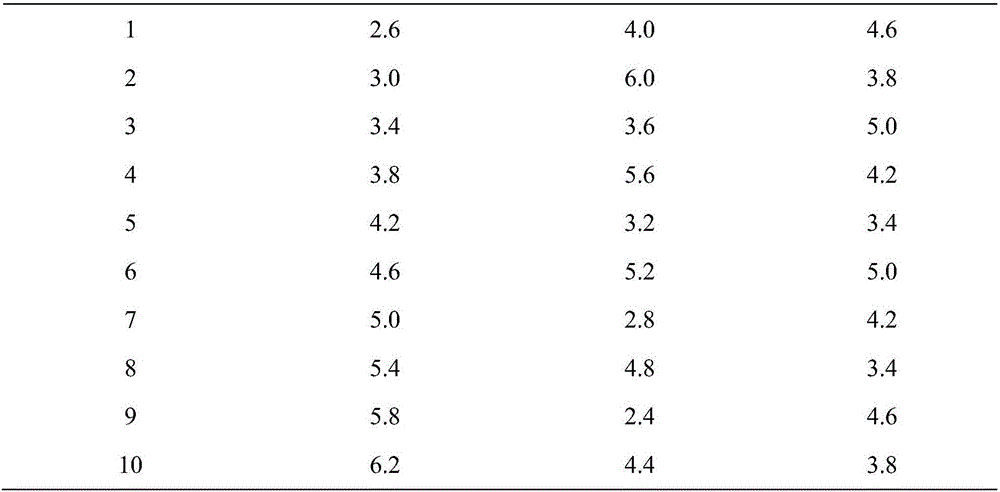

[0068] The preparation ( / 50g) of table 4 equal level homogeneous design mixing standard

[0069]

Embodiment 3

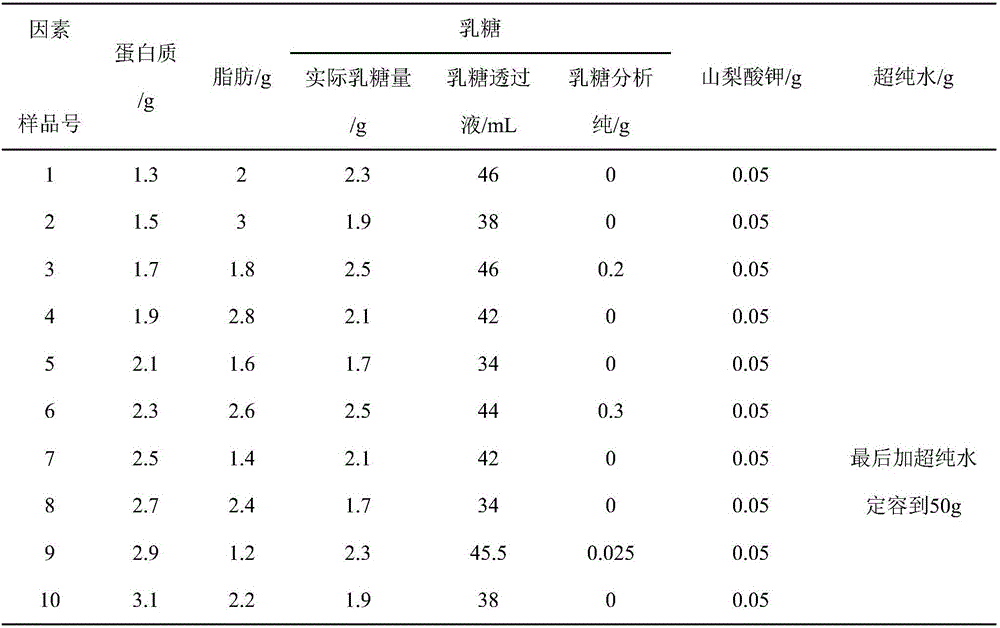

[0070] Embodiment 3: Add the comparison of the mixed standard substance prepared by the emulsifier group and the control group

[0071] Add an emulsifier—sucrose ester (because the sample needs to be heated and stirred in a 40°C water bath to dissolve after preparation of the standard product, and the sucrose ester is easily soluble in warm water), and the addition amount is 0.2%. In this test, each milliliter of lactose permeate contains about 0.065g of lactose. According to the final mass of 50g of the standard product, it can meet the requirement of lactose mass percentage content, and there is no need to add lactose of analytical grade. When carrying out sample configuration, configure with reference to Table 1, the rest of the steps are the same as in Example 1, and the specific configuration table is as shown in Table 5:

[0072] The preparation ( / 50g) of the mixed standard substance that adds emulsifier in table 5

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com