Preparation method of standard sub-cell of four-junction gallium arsenide solar cell

A standard sub-cell and solar cell technology, applied in the field of standard sub-cell preparation of four-junction gallium arsenide solar cells, can solve the problems of complex process, high cost, difference in spectral response, etc., and achieve simplified process steps, good consistency, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0033] Such as Figure 1 to Figure 5 Shown, technical scheme of the present invention is:

[0034] A standard sub-cell preparation method for a four-junction gallium arsenide solar cell, comprising:

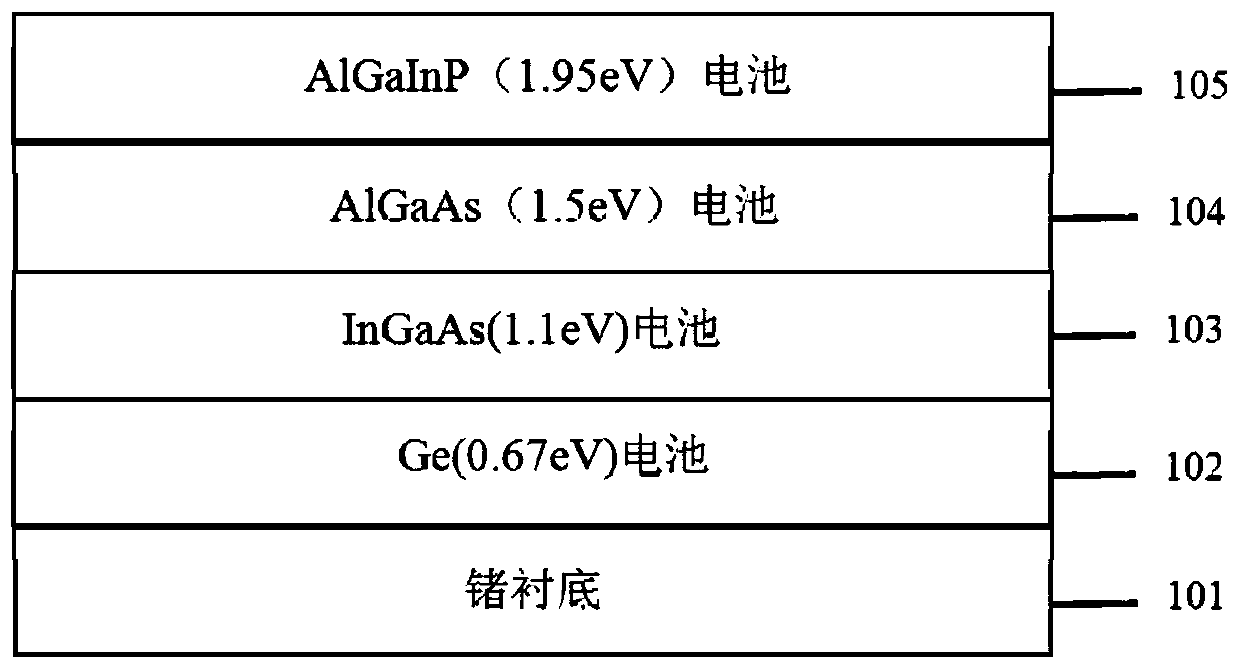

[0035] Please check figure 1 1. Using metal-organic chemical vapor deposition (MOCVD) to forward grow four-junction gallium arsenide solar cells, and sequentially grow Ge (0.67eV) cells 102, InGaAs (1.1eV) cells 103, AlGaAs (1.5eV) cells on a germanium substrate 101 ) battery 104, AlGaInP (1.95eV) battery 105.

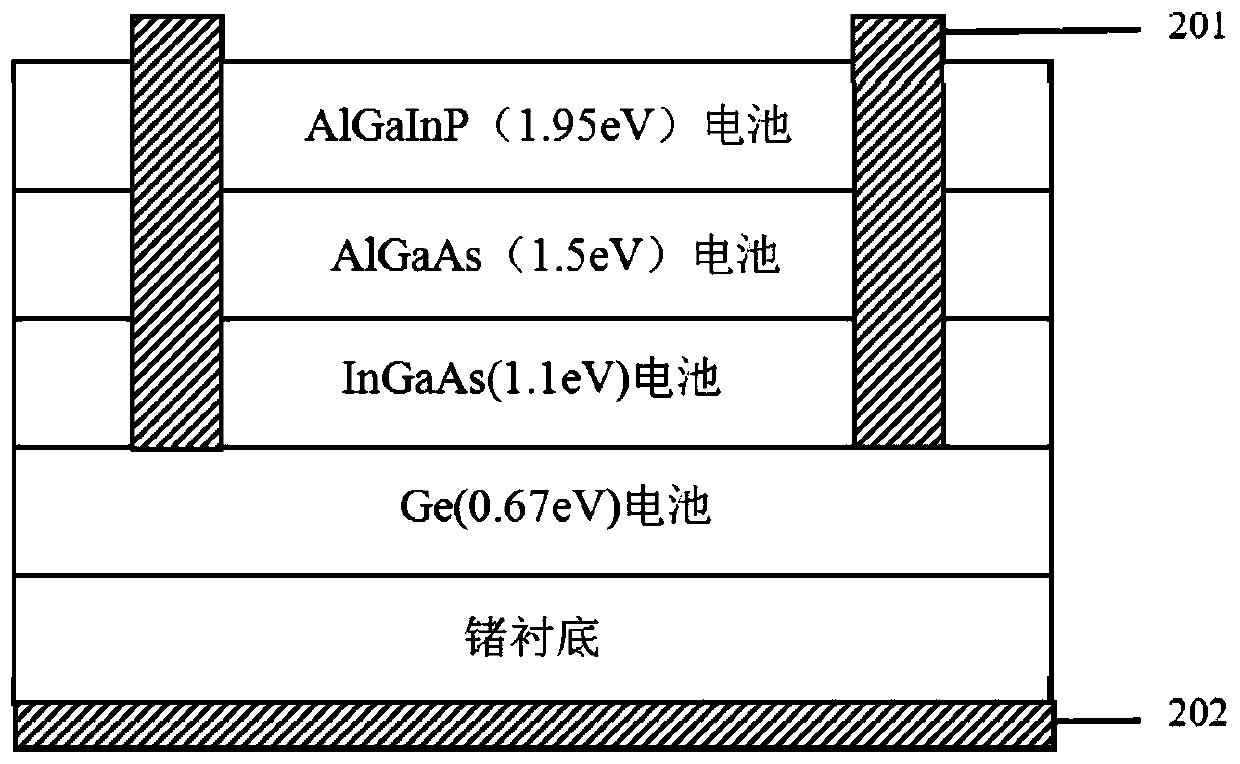

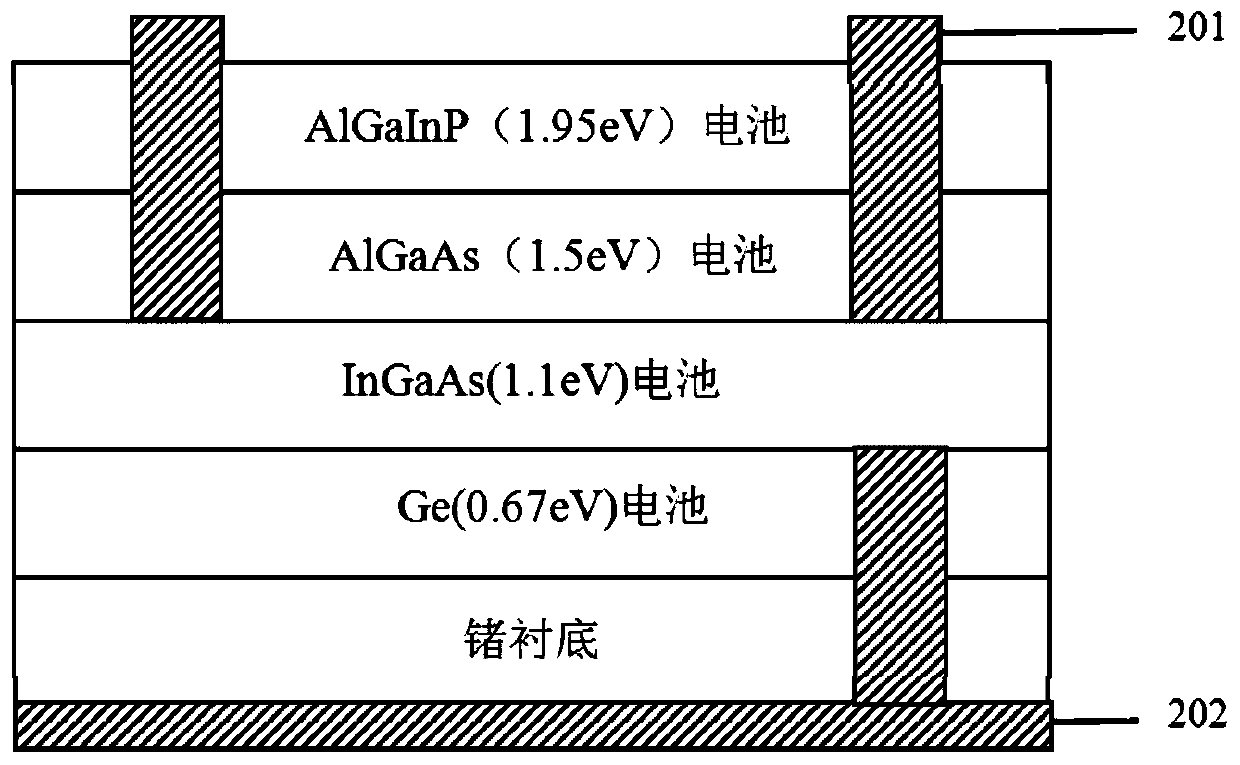

[0036] Please check figure 2 1. Prepare a Ge (0.67eV) standard sub-cell based on a four-junction gallium arsenide solar cell as a whole. On the front of the four-junction cell epitaxial wafer, the upper electrode grid line pattern ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com