Acidic mist treating device of salt mist tester

A technology of salt spray test and treatment device, which is applied to measurement devices, instruments, analytical materials, etc., can solve problems such as poor working environment, and achieve the effect of avoiding direct emptying, eliminating acidic salt spray, and solving poor working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

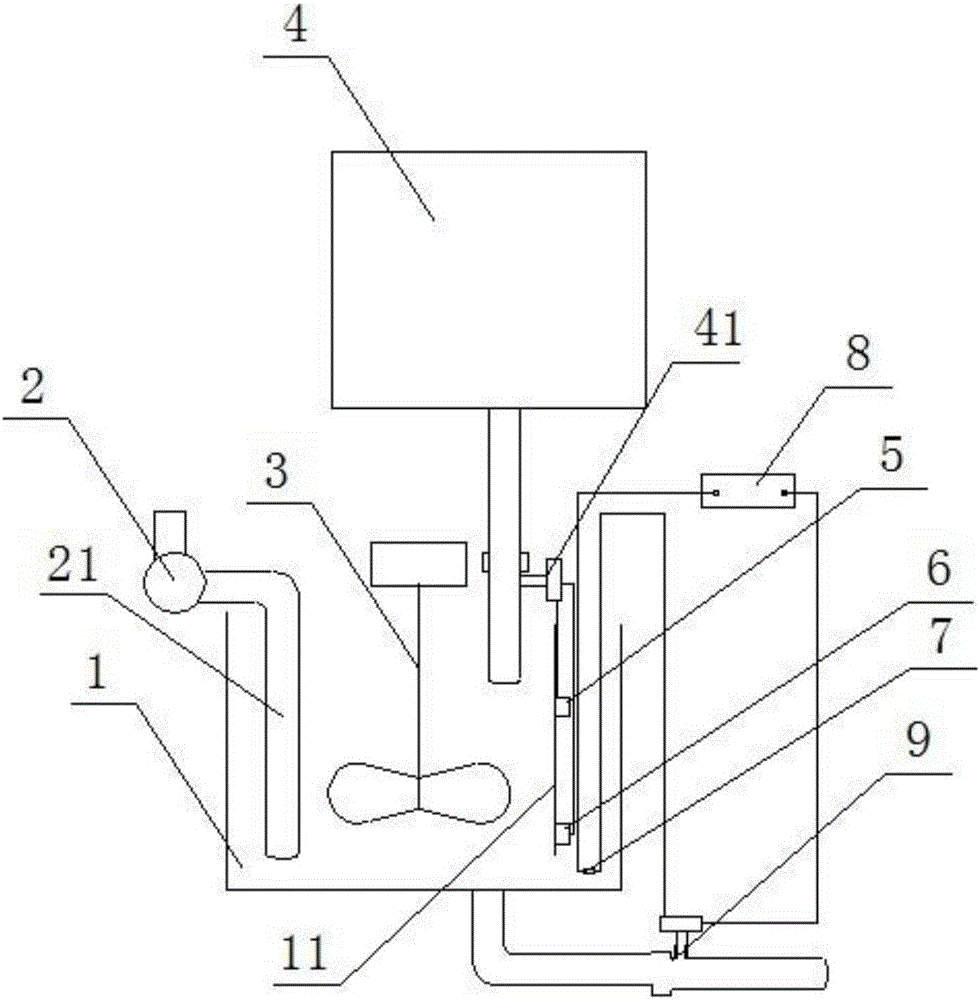

[0023] like figure 1 As shown, an acid mist treatment device for a salt spray test machine includes an acid mist treatment tank 1 and an exhaust fan 2 whose air inlet is arranged inside the salt spray test machine box. The acid mist treatment tank 1 is equipped with lye. A stirring device 3 is provided in the lye, and the air outlet pipe 21 of the exhaust fan 2 is arranged in the acid mist treatment tank 1 .

[0024] The operation steps of this embodiment are: after the acid salt spray test in the salt spray test chamber is completed, turn on the exhaust fan 2 and keep it for 3-5 minutes until all the acid mist in the inner cavity of the salt spray test chamber is sucked into the acid mist treatment tank 1, then turn on the stirring device 3 to fully neutralize the acid mist and lye, and finally turn on the salt spray test chamber.

[0025] A pH detector is installed in the inner cavity of the salt spray test chamber to detect whether all the acid mist in the inner cavity of ...

Embodiment 2

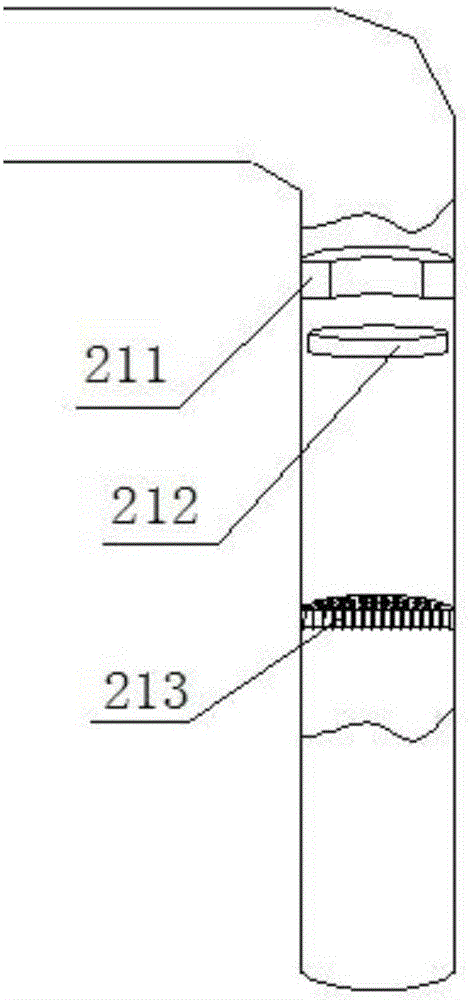

[0028] like figure 2 As shown, it is further optimized on the basis of the acid mist treatment device of a salt spray tester described in Example 1, the air outlet pipe 21 of the exhaust fan 2 extends below the liquid level of the lye, and the air outlet The pipe 21 is provided with a fixed block 211, a floating block 212, and a fixed sieve plate 213 sequentially from top to bottom, the fixed block 211 is fixed inside the air outlet pipe 21, the floating block 212 is cylindrical, and the diameter of the floating block 212 The gap distance greater than that of the fixed block 211 is smaller than the inner diameter of the air outlet pipe 21 , and the fixed sieve plate 213 is fixed inside the air outlet pipe 21 , and several through holes are provided on the fixed sieve plate 213 .

[0029] In this embodiment, the bottom of the air outlet pipe 21 extends into the setting below the liquid level of the acid mist treatment tank 1 so that the acidic salt mist fully contacts with the...

Embodiment 3

[0031] On the basis of the acid mist treatment device of a salt spray tester described in Example 1, it is further optimized. The acid mist treatment tank 1 is provided with a pH detection device, and the top of the acid mist treatment tank 1 is provided with a lye storage The tank 4, the pipeline between the acid mist treatment tank 1 and the lye storage tank 4 is provided with an lye control valve 41, and the bottom of the acid mist treatment tank 1 is provided with a treatment liquid control valve 9.

[0032]The operation steps of this embodiment are: when the pH detection device detects that the pH value of the treatment liquid in the acid mist treatment tank 1 is less than 7.5, open the treatment liquid control valve 9, discharge the treatment liquid in the acid mist treatment tank 1, and then Close the treatment liquid control valve 9, open the lye control valve 41, close the lye control valve 41 until suitable new lye is loaded into; When the value is less than 7.5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com