Waste heat recovery system for hydrophobic expansion container of waste power plant

A technology of waste heat recovery system and water-repellent expansion vessel, which is applied in the direction of feed water heater, preheating, supplementary feed water, etc., can solve the problems that affect the safe and civilized production of power plants, increase the loss of soda and heat, and increase the unsafe factors in the plant area, etc., to achieve Avoid the direct exhaust of exhaust steam, save energy, and benefit the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

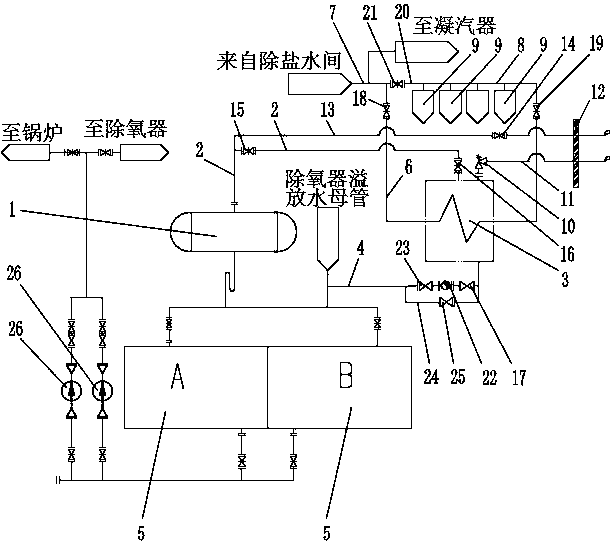

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, the waste heat recovery system is used for the waste heat recovery system of the expansion vessel of the garbage power plant. The bottom of the expansion vessel 1 is connected to the drainage box 5, and the drainage box 5 is connected to the deaerator 9 and the boiler through the drainage pump 26 (not shown in the figure). The top of the hydrophobic expander 1 is connected with an exhaust pipe 2, and the exhaust pipe 2 is connected with a heat exchanger 3. The heat exchanger 3 includes a shell side and a tube side. The top of the shell side has a steam inlet, and the bottom has a condensate outlet. The tube side includes desalted water inlet and desalted water outlet, exhaust pipe 2 is connected to steam inlet, condensed water outlet is connected to drain tank 5 through condensed water pipe 4, desalted water inlet is connected to desal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com