Environment-friendly blowing-down and blowing-in method for blast furnace

A blast furnace, environmental protection technology, applied in the direction of blast furnace, blast furnace details, blast furnace parts, etc., can solve the problems of difficult purification equipment, impact on the environment and the health of residents, etc., achieve good dust removal effect, less investment, and reduce emission pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] When the blast furnace is closed for air supply, the technical requirement is to directly discharge part of the black with flare exhaust gas through the large diffuser on the top of the furnace. The inventor often encounters residents calling the police and complaining in actual work, which also brings great harm to the normal production work of iron and steel enterprises. However, installing new purification equipment on the top of the furnace not only affects safe production, but also makes maintenance more complicated and increases production costs. Therefore, the problem has not been solved well. Therefore, the inventor proposed an idea to replace the air supply gas Guide through the original dust removal device to solve the problem.

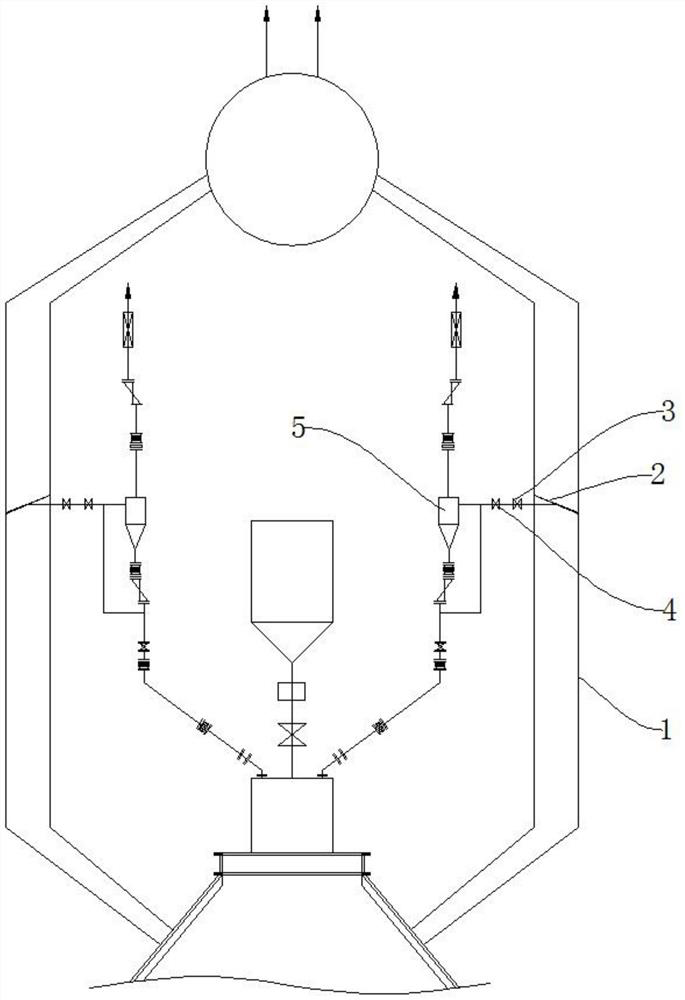

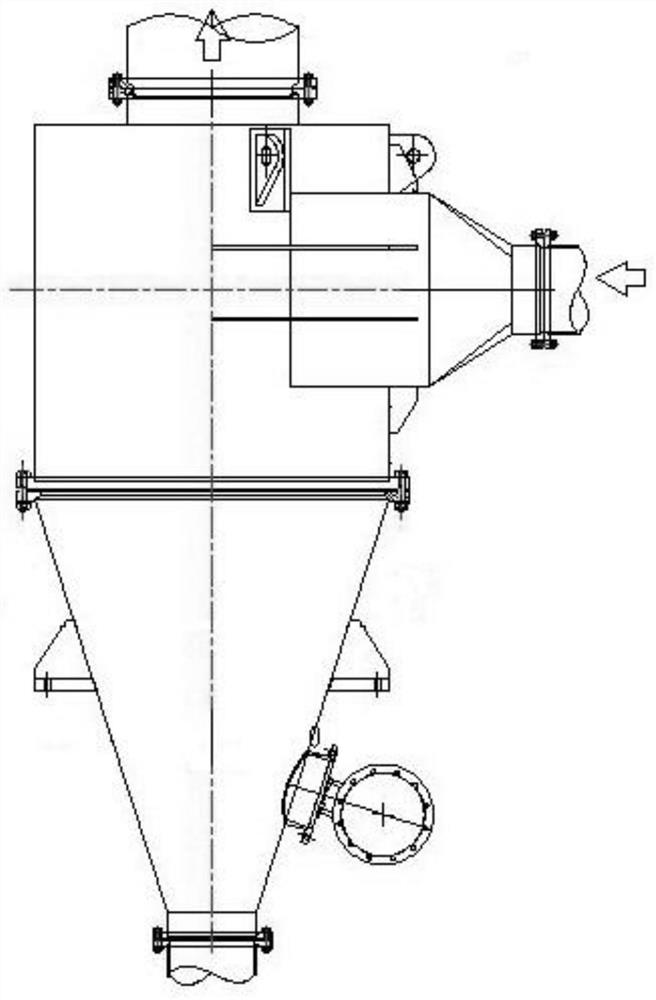

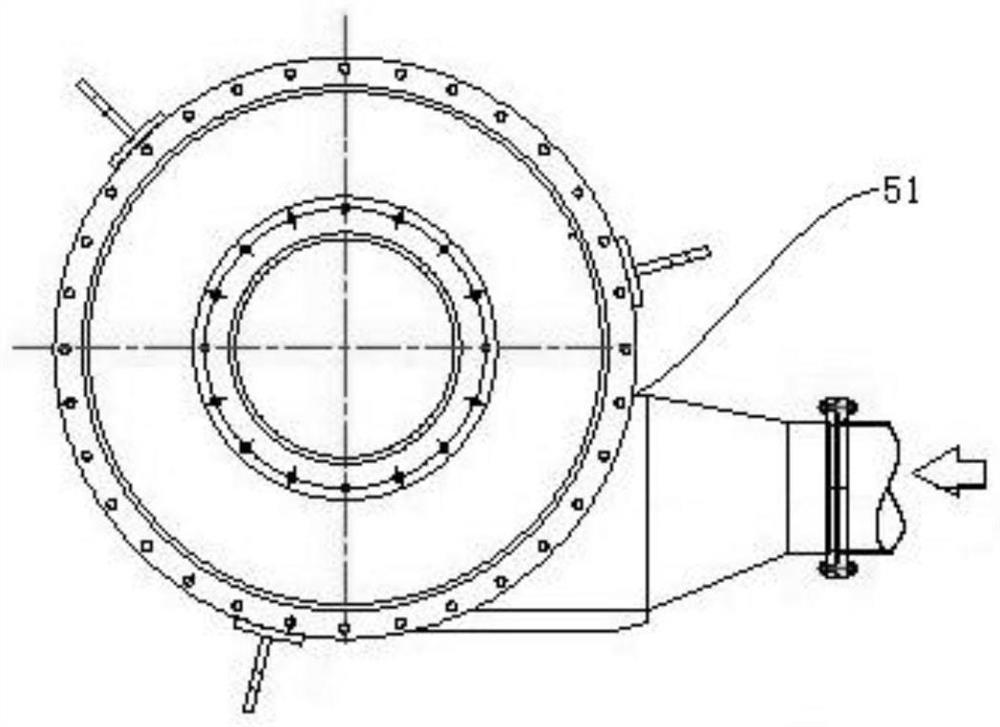

[0025] see Figure 1 to Figure 3 , a blast furnace environment-friendly air supply method, comprising the following specific steps:

[0026] Step S1, transformation: add connecting pipe 2 so that one end of it is connected to the ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com