Environment-friendly and energy-saving coking device and working method thereof

A coking device, environmental protection and energy-saving technology, applied in the chemical industry, coke oven, petroleum industry, etc., can solve the problems of difficult balance of heat generation, complex equipment structure, semi-coke quality decline, etc., to reduce external pollution and speed up the processing process , is conducive to the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

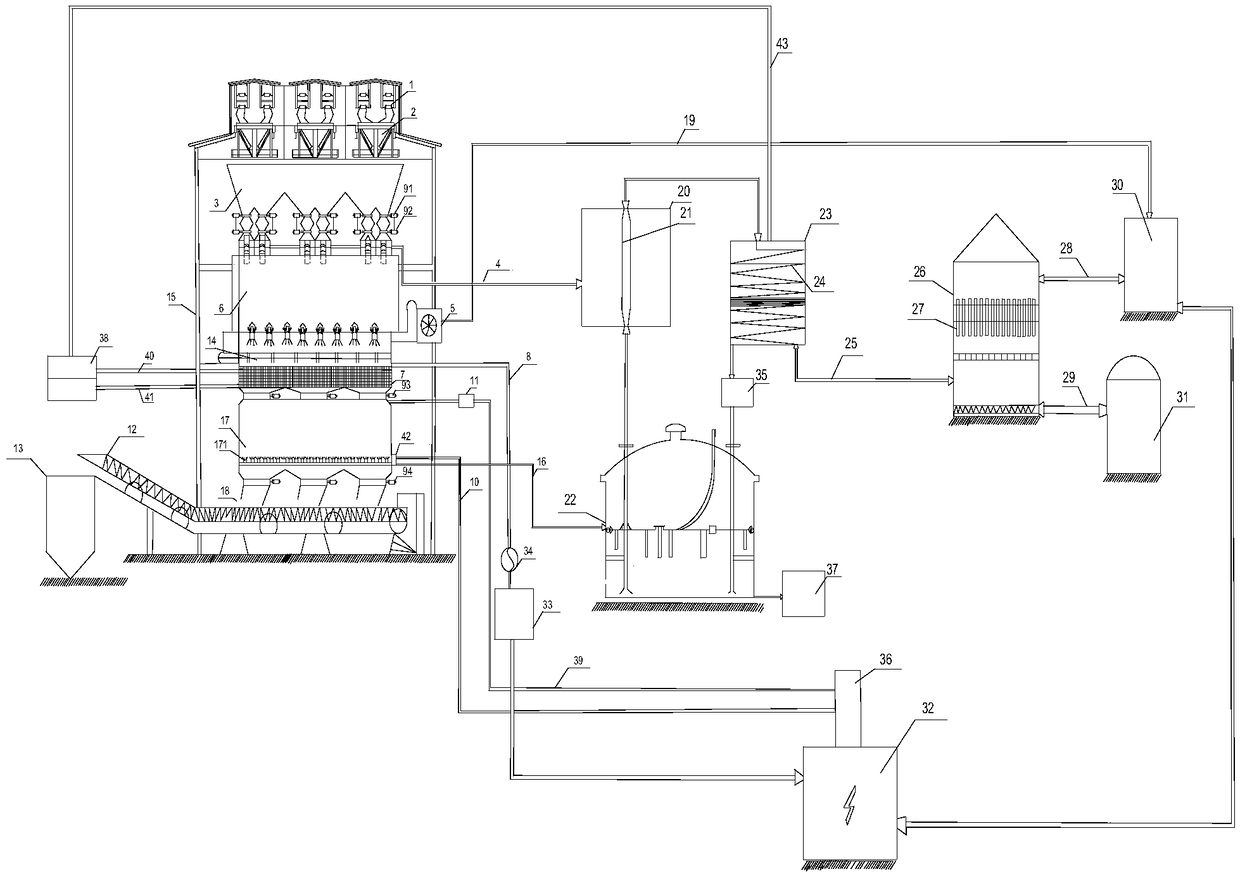

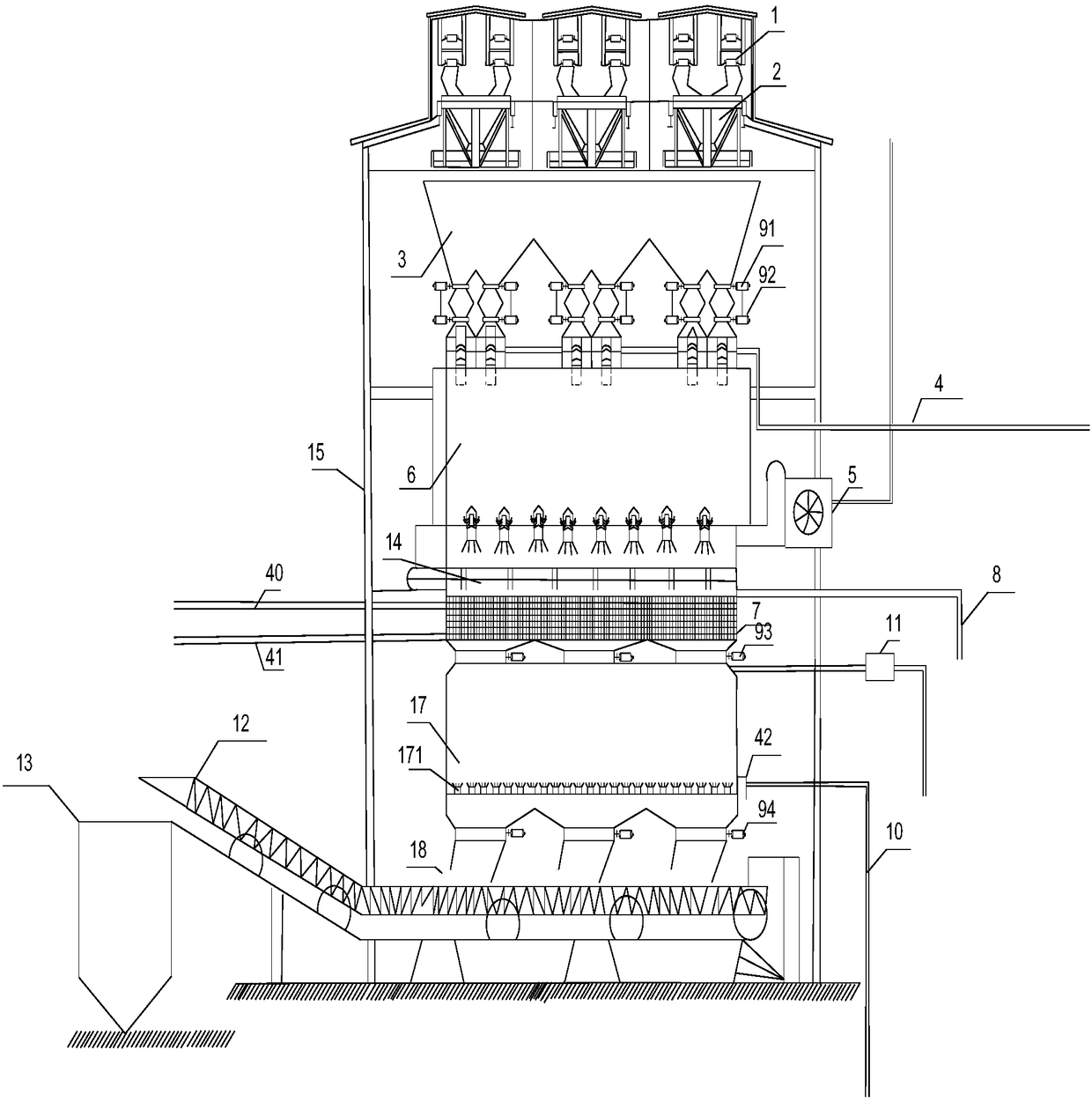

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as figure 1 As shown, an environmental protection and energy-saving coking device includes a coke oven 15, an electric tar catcher 26, a tar ammonia water clarification tank 22 and a power plant 32, wherein: a drying section 3 and a dry distillation section 6 are sequentially arranged in the coke oven 15 from top to bottom and the coke quenching section 17, between the coke quenching section 17 and the carbonization section 6, there is a water wall 7 for radiative heat exchange with the coal burned in the carbonization section 6, and the steam outlet pipe 8 of the water wall 7 passes through the fan 34 and the waste heat boiler 33 in sequence Entering the power plant 32, the water wall 7 is also communicated with the circulating cold water pool 38 through the circulating water inlet pipe 40 and the circulating water outlet pipe 41, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com