Method for identifying mutual position relationship of horizontally moving shafts and rotating shaft of multi-axis numerically-controlled machine tool

A CNC machine tool and mutual position technology, which is applied in metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of less research on measurement methods and difficult accuracy detection of multi-axis machine tools, so as to improve the overall processing accuracy. , Accurate identification, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

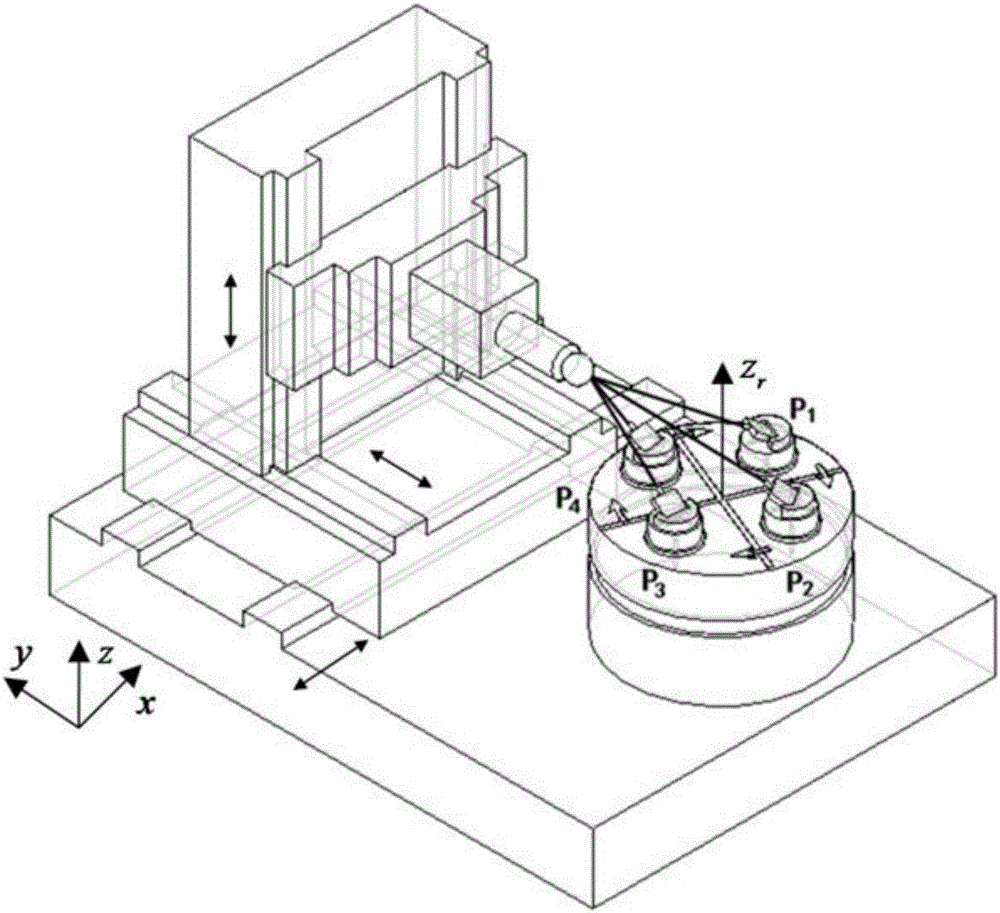

[0113] When measuring, install the cat's eye at a suitable position near the main shaft of the turning and milling machining center, and move with the main shaft. Control the translational parts of the turning and milling machining center to feed in 3D space along the preset path, the movement area is 1200mm×600mm×500mm, and the laser tracker tracks and measures the movement of the translational parts in real time.

[0114] When the translational part is fed along the x, y, and z axes, a measurement point is set for every 100mm of movement, and the total number of measurement points is 87. When the translation component moves to the position of each measurement point, it is controlled to stop for 5 seconds, and the measurement data of the laser tracker at the current position is recorded.

[0115] The first base station position P of the laser tracker on the turntable 1 During the measurement, the translation part is controlled to feed along the preset path, and when the lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com