Method for printing liquid metal on paper surface

A liquid metal, printing paper technology, applied in printing devices, copying/marking methods, printing and other directions, can solve problems such as inability to print, and achieve the effects of improving wettability, realizing mass production, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

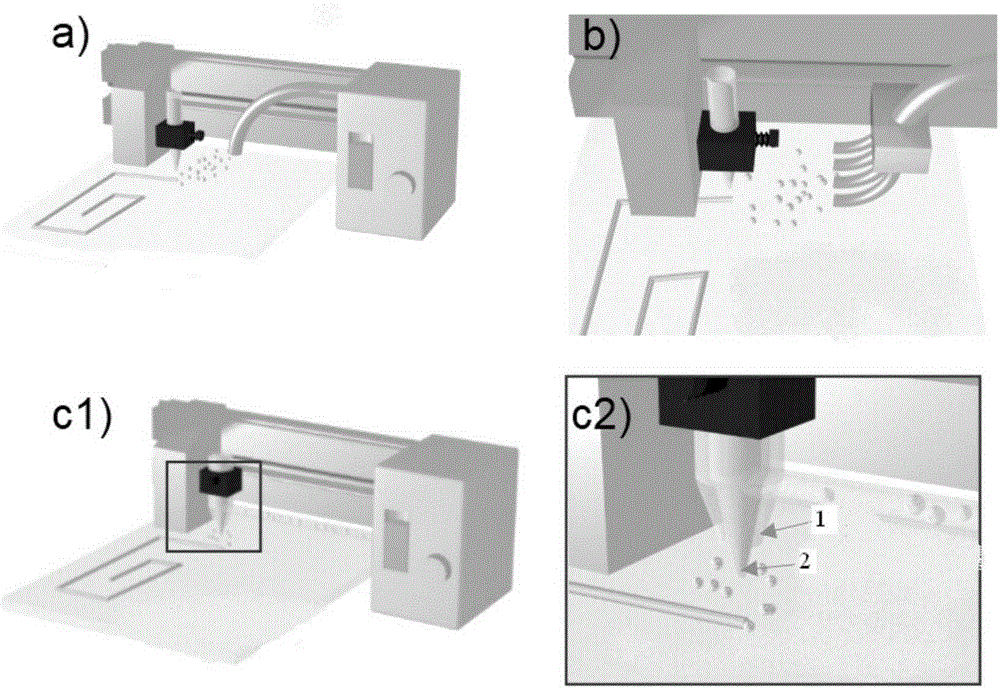

[0031] This embodiment relates to a method for liquid metal printing on paper, including the following steps:

[0032] 1) Take A4 printing paper, and use a single spray nozzle to spray evenly on its surface. During the spraying process, control the diameter of the water vapor in the mist to be 10-50μm, the outlet velocity of the mist to be 0.1-0.3m / s, and the distance between the nozzles The paper surface is 1-5cm, the relative humidity of the printing paper surface is 100%, spray for 1-4s, stop spraying, and get the sprayed printing paper;

[0033] 2) standing and soaking the sprayed printing paper for 1-4s until the water content of the printing paper is 0.2-1%;

[0034] 3) Use a liquid metal printer to perform Ga liquid metal printing on the surface of the printing paper after standing to obtain a linear printed product. During the printing process, the printing pen and the printing paper are in contact with each other.

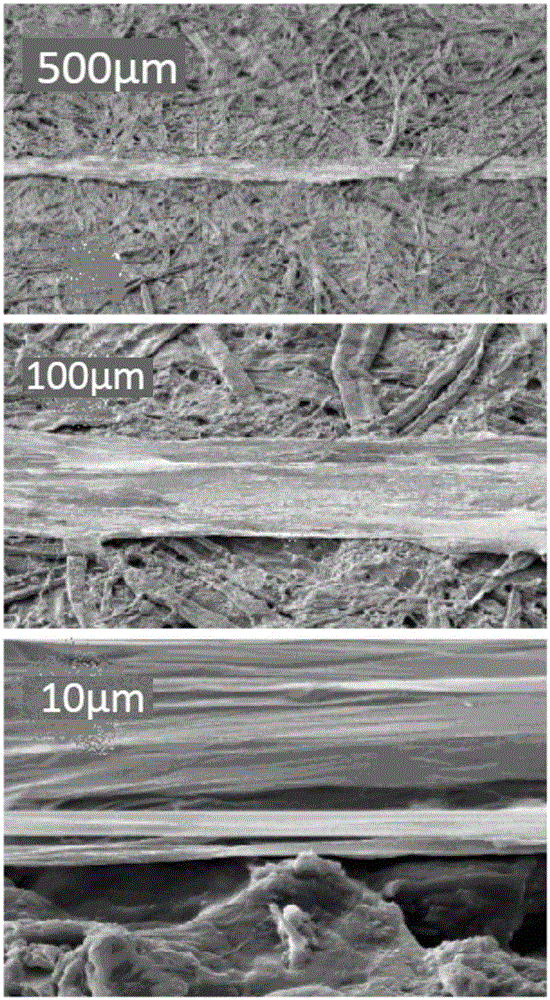

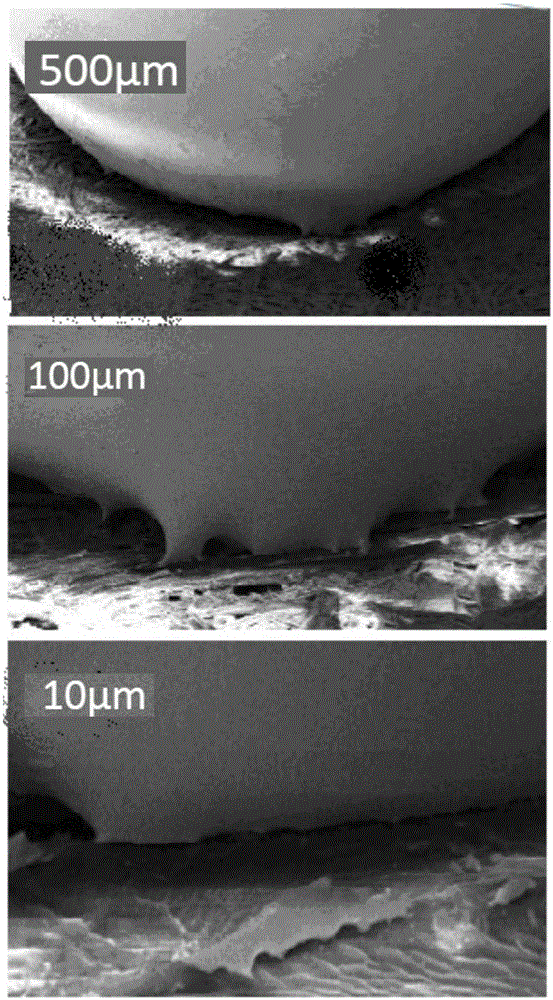

[0035] The scanning electron microscope picture of...

Embodiment 2

[0037] This embodiment relates to a method for liquid metal printing on paper, including the following steps:

[0038] 1) Take A4 printing paper and spray it evenly on the surface with a multi-spray nozzle. During the spraying process, control the diameter of the water vapor in the mist to be 10-50μm, the outlet velocity of the mist to be 0.1-0.3m / s, and the distance between the nozzles The paper surface is 1-5cm, the relative humidity of the printing paper surface is 10%, spray for 1-4s, stop spraying, and get the sprayed printing paper;

[0039] 2) standing and soaking the sprayed printing paper for 1-4s until the water content of the printing paper is 0.2-1%;

[0040] 3) Use a liquid metal printer to perform Ga 75.5 In 24.5 Metal printing, get linear printing products. During the printing process, the printing pen and the printing paper are in contact with each other.

[0041] The schematic diagram of the printing process in this embodiment is as follows figure 1 b)

Embodiment 3

[0043] This embodiment relates to a method for liquid metal printing on paper, including the following steps:

[0044] 1) Take A4 printing paper, and use the sleeve spray nozzle to spray evenly on its surface. During the spraying process, control the diameter of the water vapor in the mist to be 10-50 μm, the outlet velocity of the mist to be 0.1-0.3m / s, and the nozzle distance The paper surface is 1cm, the relative humidity of the printing paper surface is 100%, spray for 1s, stop spraying, and get the sprayed printing paper;

[0045] 2) Let the sprayed printing paper stand and soak for 1 second until the water content of the printing paper is 0.2%;

[0046] 3) Use a liquid metal printer to perform Ga 75.5 In 24.5 Metal printing, to obtain liquid metal wire printing products. During the printing process, the printing pen and the printing paper are in contact with each other.

[0047] The schematic diagram of the printing process in this embodiment is as follows figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com