Instant dry sublimation transfer digital paper

A thermal sublimation, digital paper technology, applied in printing, copying/marking method, temperature recording method, etc., can solve the problem that the drying speed cannot meet the printing speed requirement, achieve ideal transfer effect, increase ink absorption, Improve the effect of fast delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

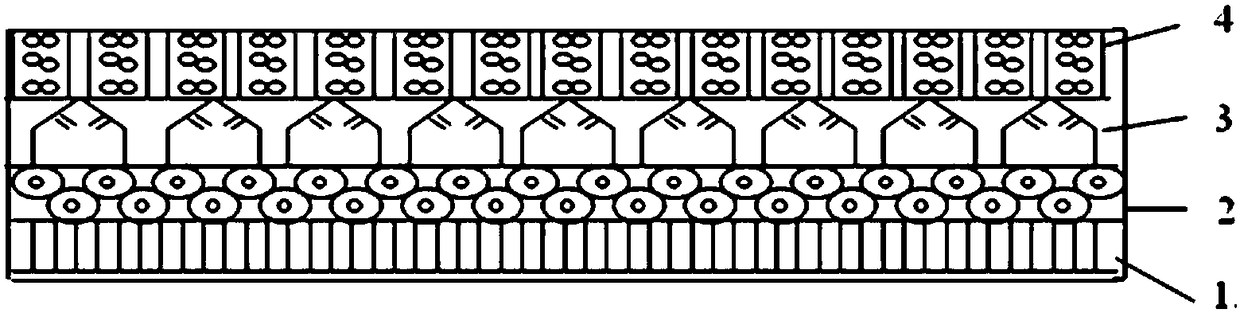

[0036] Instant dry sublimation transfer digital paper, such as figure 1 As shown, base paper 1, water-absorbing and permeable layer 2, porous layer 3, and surface channel layer 4 are sequentially included from bottom to top.

[0037] The surface channel layer 4 is calculated by mass percentage, and the components and contents are as follows:

[0038] Resin composite 92%;

[0039] Porous silica 8%;

[0040] Wherein, the resin compound is composed of polyvinyl acetate with a mass percentage of 70% and a vinyl alcohol-vinyl acetate copolymer with a mass percentage of 30%. The mass of the channel layer 4 on the upper surface of the substrate paper 1 per square meter is 2.0 g.

[0041] The porous layer 3 is made of 62% by mass of cellulose, 30% by mass of cationic modified polyacrylamide, and is prepared by reacting 8% by mass of diisocyanate, and the cellulose is made of 20% by mass of hydroxyethyl Cellulose and 80% by mass of hydroxypropyl cellulose, cationic modified polyacr...

Embodiment 2

[0047] Instant dry sublimation transfer digital paper, such as figure 1 As shown, base paper 1, water-absorbing and permeable layer 2, porous layer 3, and surface channel layer 4 are sequentially included from bottom to top.

[0048] The surface channel layer 4 is calculated by mass percentage, and the components and contents are as follows:

[0049] Resin composite 75%;

[0050] Porous silica 25%;

[0051] Wherein, the resin compound is composed of ethylene-vinyl alcohol-vinyl acetate copolymer with a mass percentage of 50% and sodium carboxymethyl cellulose with a mass percentage of 50%. The mass of the channel layer 4 on the upper surface of the substrate paper 1 per square meter is 3.0 g.

[0052] Porous layer 3 is made of 75% by mass percentage of cellulose, 20% by mass percentage of cationic modified starch by reacting 5% of diisocyanate by mass percentage, and the cellulose is made of 30% by mass of carboxymethyl cellulose and 70% by mass of hydroxyethyl cellulose, ...

Embodiment 3

[0058] Instant dry sublimation transfer digital paper, such as figure 1 As shown, base paper 1, water-absorbing and permeable layer 2, porous layer 3, and surface channel layer 4 are sequentially included from bottom to top.

[0059] The surface channel layer 4 is calculated by mass percentage, and the components and contents are as follows:

[0060] Resin composite 60%;

[0061] Porous silica 40%;

[0062] Wherein, the resin composite is composed of vinyl alcohol-vinyl acetate copolymer with a mass percentage of 45% and sodium carboxymethyl cellulose with a mass percentage of 55%. The mass of the channel layer 4 on the upper surface of the substrate paper 1 per square meter is 2.4 g.

[0063] Porous layer 3 is made by the reaction of 7% diisocyanate by mass percent of 68% sodium carboxymethyl cellulose, 25% by mass of cationic modified starch, and the diisocyanate is 50% by mass of H 12 MDI and 50% by weight of p-phenylene diisocyanate. The mass of the porous layer 3 on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com