Ornithopter with elastic wings

A flapping-wing aircraft and elastic technology, applied in the field of bionic flapping-wing aircraft, can solve the problems of flapping wings, poor manned driving comfort, heavy fuselage structure, etc., achieve flexible flight attitude adjustment, improve flight flexibility, and solve rolling problems. The effect of turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] The technical solutions provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

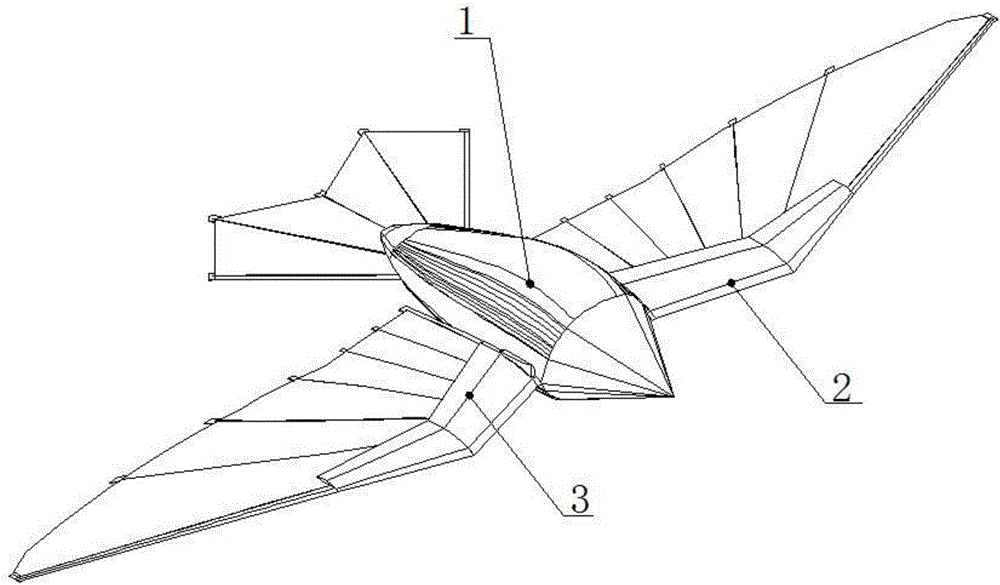

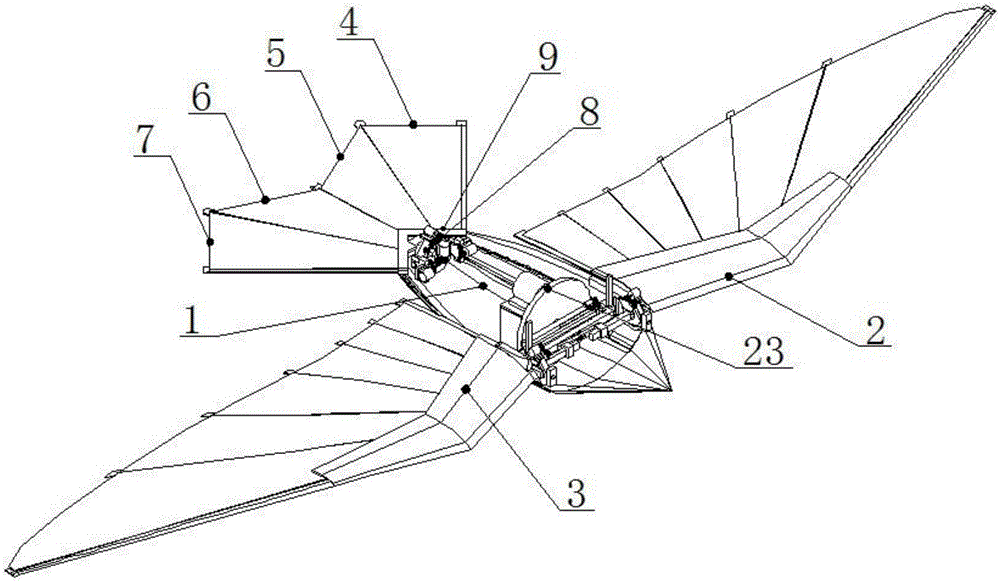

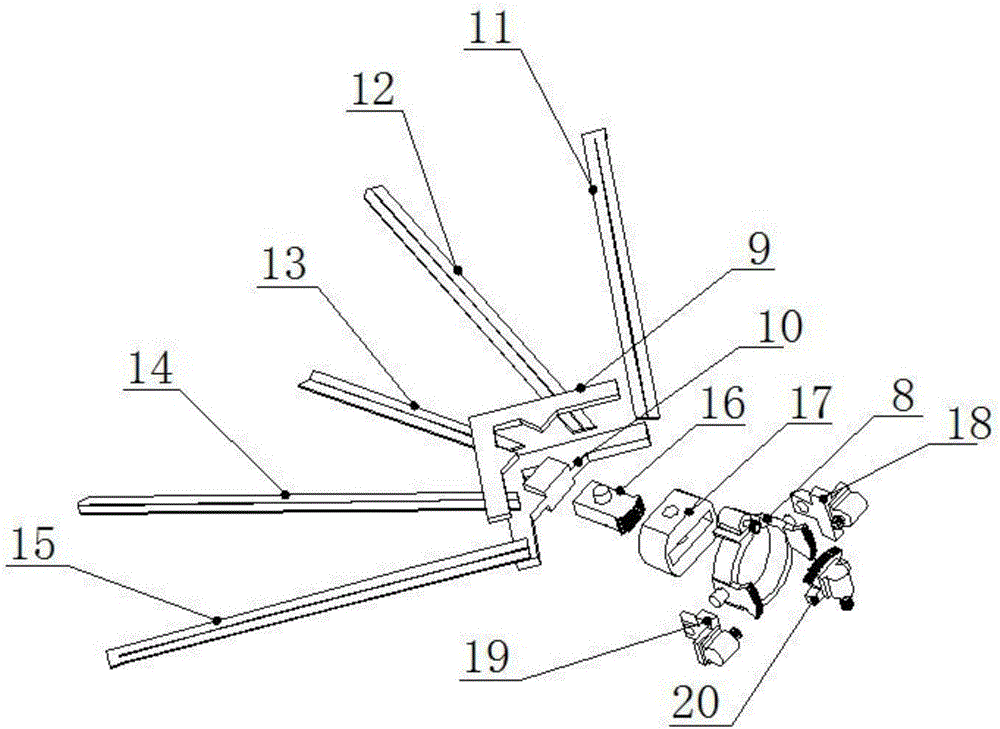

[0050] Such as figure 1 , figure 2 , Figure 5 As shown, the flapping-wing aircraft with elastic wings provided in this embodiment includes a fuselage main body 1, a left elastic wing 2, a right elastic wing 3, an elastic empennage 4, a flapping wing transmission mechanism, and an adjustable support three-point landing gear. Wherein the flapping wing transmission mechanism is installed and fixed on the middle section of the fuselage main body 1, the left elastic wing 2 is installed by the left wing connecting plate 45 on the left side of the fuselage main body middle section, and the right elastic wing is installed by the right wing connecting plate 44 on the right side of the fuselage main body middle section wing3. Elastic empennage is fixedly installed in fuselage body afterbody by left and right empennage swing supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com