Preparation method of concrete early strength agent

A technology of early strength agent and concrete, which is applied in the field of preparation of concrete early strength agent, can solve the problems of unsatisfactory concrete strength, restrict the development of early strength agent, increase the preparation cost, etc., and achieve the reduction of preparation cost and good early strength effect , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

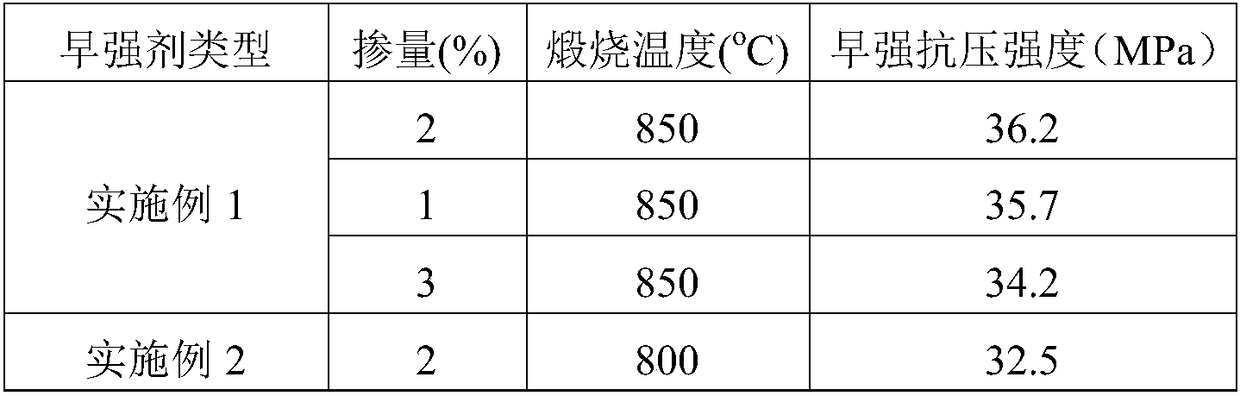

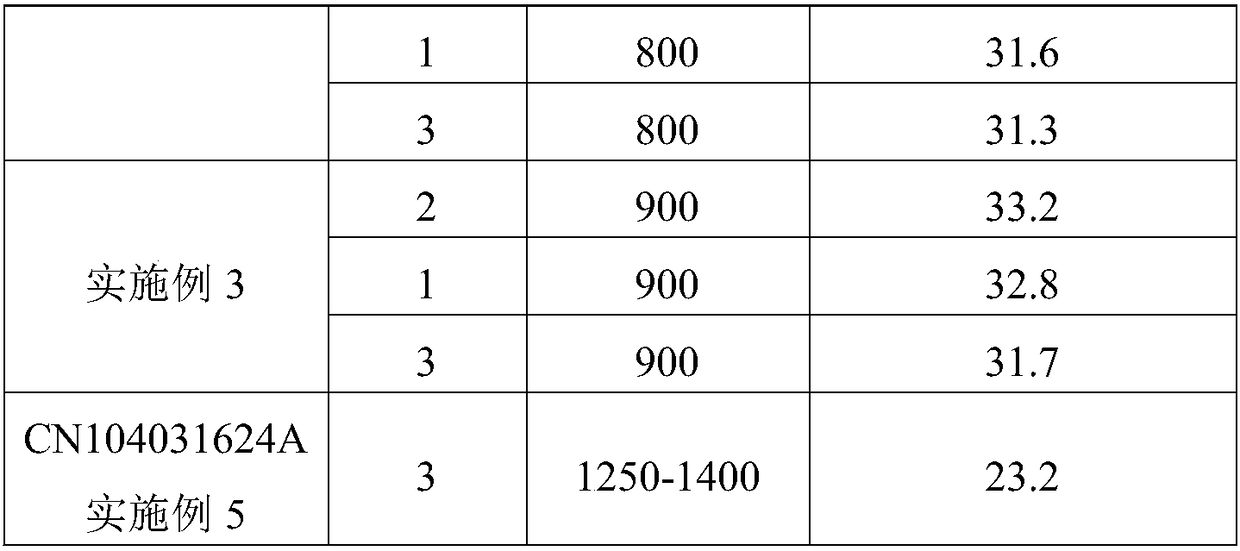

Examples

preparation example Construction

[0030] The present invention provides a method for preparing a concrete early strength agent. In order to achieve the purpose, technical scheme and effect of the present invention to be more clear and definite, the present invention will be further described in detail below.

[0031] A concrete early-strength agent, made of the following components in proportion by weight: 20-30 parts of CaO, 20-30 parts of Al 2 o 3 15~25 parts, TiO 2 3~5 parts, FeSO 4 4 to 6 parts, 10 to 15 parts of silica fume, 15 to 20 parts of fluorite powder, Y 2 o 3 0.5~0.7 parts, Li 2 CO 3 1-3 parts, NaCl 0.1-0.3 parts, KCl 0.1-0.3 parts;

[0032] The preparation method of described concrete accelerator comprises the following steps:

[0033] 1) The above-mentioned components are divided into components according to the weight ratio: absolute ethanol: zirconia ball = 1:1:3, and the material is placed on a ball mill with a rotating speed of 200-300 rpm for 6-8 hours;

[0034] 2) Sieve, dry, ...

Embodiment 1

[0041] A concrete accelerator, made of the following components by weight: 25 parts of CaO, 25 parts of Al 2 o 3 20 parts, TiO 2 4 parts, FeSO 4 5 parts, microsilica fume 12 parts, fluorite powder 18 parts, Y 2 o 3 0.6 parts, Li 2 CO 32 parts, 0.2 parts of NaCl, 0.2 parts of KCl;

[0042] The preparation method of described concrete accelerator comprises the following steps:

[0043] 1) The above-mentioned components are divided into components according to the weight ratio: absolute ethanol: zirconia balls = 1:1:3, and the material is placed on a ball mill with a rotating speed of 250 rpm for 7 hours;

[0044] 2) Screening, drying, and dry pressing in a stainless steel mold for molding and demoulding; and placing the demoulded sample in a muffle furnace at 850°C for 1.5 hours for calcination, and cooling naturally;

[0045] 3) Crushed into 100 mesh powder, and washed with deionized water until AgNO 3 Check until no precipitation occurs;

[0046] 4) Add 5 parts of...

Embodiment 2

[0050] A concrete early-strength agent, made of the following components in proportions by weight: 20 parts of CaO, 20 parts of Al 2 o 3 15 parts, TiO 2 3 parts, FeSO 4 4 parts, microsilica fume 10 parts, fluorite powder 15 parts, Y 2 o 3 0.5 parts, Li 2 CO 3 1 part, NaCl 0.1 part, KCl 0.1 part.

[0051] The preparation method of described concrete accelerator comprises the following steps:

[0052] 1) The above-mentioned components are divided into components according to the weight ratio: absolute ethanol: zirconia balls = 1:1:3, and the material is placed on a ball mill with a rotating speed of 200 rpm for 6 hours;

[0053] 2) Screening, drying, and dry pressing in a stainless steel mold for molding and demoulding; and placing the demoulded sample in a muffle furnace at 800°C for 1 hour for calcination, and cooling naturally;

[0054] 3) Crushed into 60 mesh powder, and washed with deionized water until AgNO 3 Check until no precipitation occurs;

[0055] 4) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com