Reaction compounding type aldehyde-removing aqueous wood paint and preparation method thereof

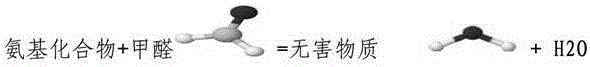

A water-based wood paint and composite technology, applied in the direction of coating, etc., can solve the problems of indoor air quality deterioration, lack of functional effects, immature technology, etc., to improve the effect of removing aldehydes, the process is simple and easy to control, The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

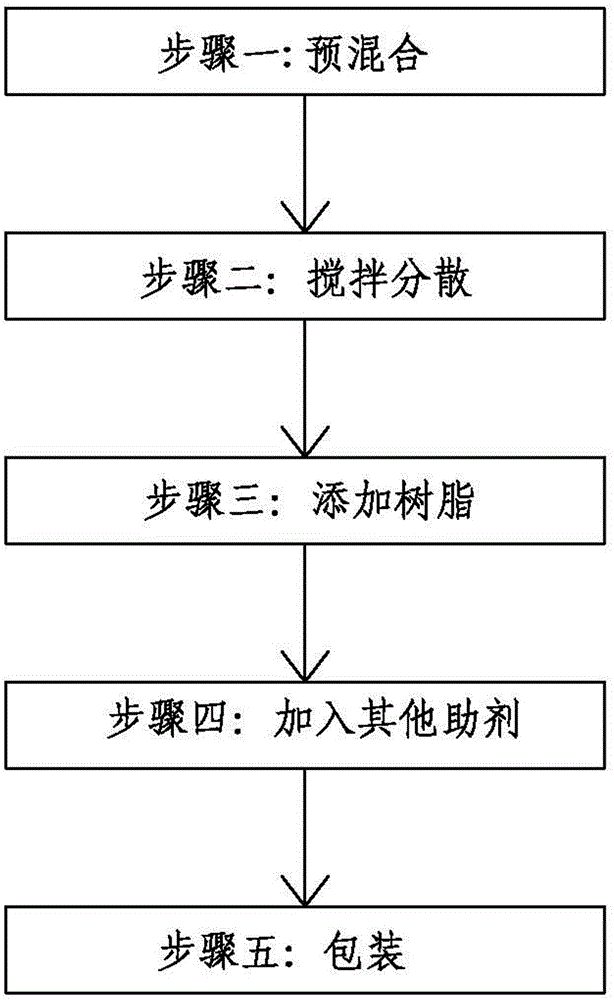

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with specific embodiment:

[0035] A kind of reactive composite type aldehyde-removing water-based wood paint is characterized in that it comprises the following components and their weight percentages:

[0036] Water: 7-15%;

[0037] Multifunctional additives: 3-4.5%;

[0038] Aminated compound raw materials: 1.5%-5%;

[0039] Pure acrylic core-shell emulsion polymer: 70-85%;

[0040] Coalescing aids: 2-5%.

[0041] As a further optimized solution, the amino compound composite raw material is an organic amino copolymer, and its optimum weight percentage is preferably between 2-4%.

[0042] The pure acrylic core-shell emulsion polymer is an acrylic emulsion, that is, a core-shell emulsion polymer.

[0043] As a better solution, the multifunctional auxiliary agent includes one or more of emulsifier, defoamer and thickener; wherein, the thickener can be a leveling agent.

[0044] The film-form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com