A water-cooling device for the main ditch of a blast furnace tapping ditch and its installation and use method

A blast furnace tapping and water-cooling technology, applied in cooling devices, discharge devices, etc., can solve the problems of gas, mechanical damage, time-consuming and energy-consuming maintenance of large trenches, and high labor intensity of workers, achieving high safety, simple structure, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

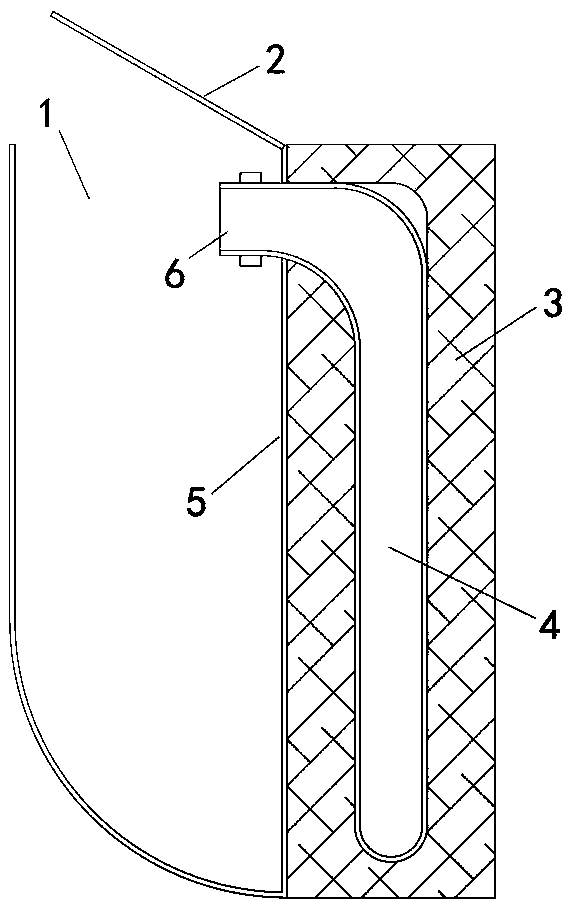

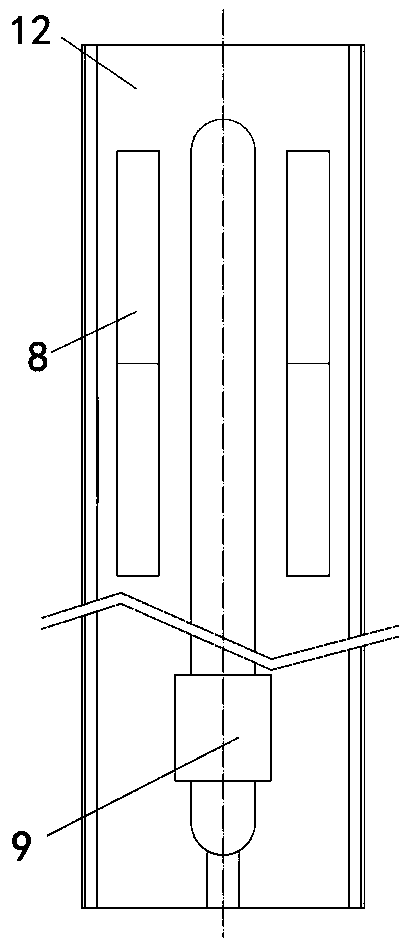

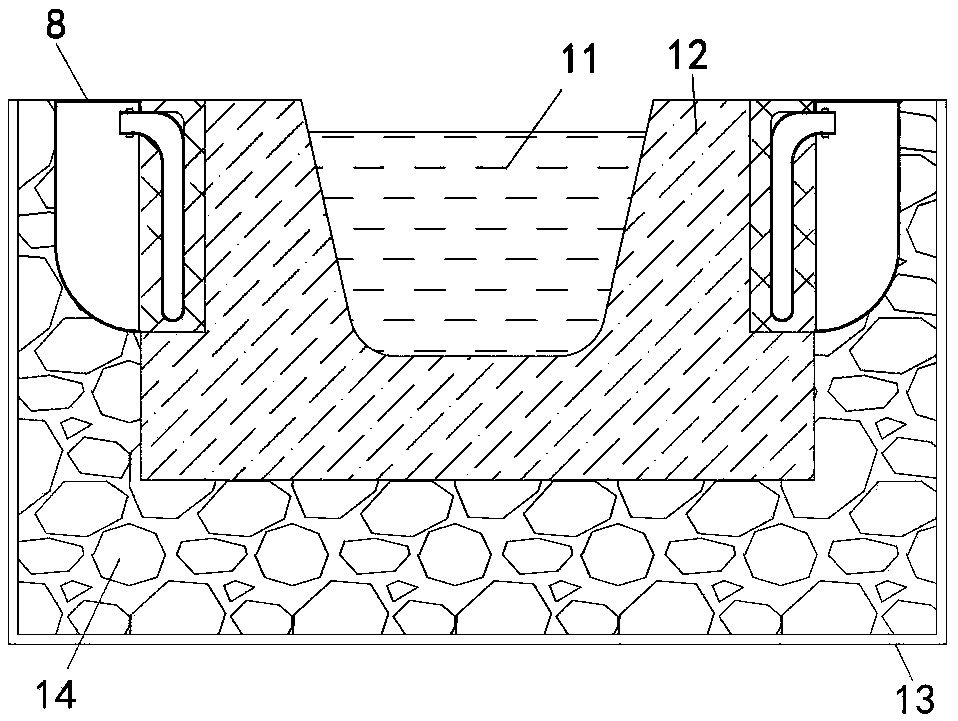

[0034] Embodiment 1: as figure 1 , figure 2 , image 3 and Figure 4 As shown, a water-cooling device for the main channel of a blast furnace tapping channel, the cooler body 8 contains a cooler cavity 1, the top of the cooler cavity 1 is connected to the sealing plate 2, the sealing plate 2 can be opened, and the metal ceramic 3 is filled in the metal back Between the plate 5 and the shell of the cooler body 8, the cooling water pipe 4 is connected in the cermet 3, the cooling water pipe 4 has a water pipe inlet section 6, and the water pipe inlet section 6 protrudes from the metal back plate 5 and is located in the cooler cavity In 1, the skimmer beam 9 and the cooler body 8 are respectively located in the iron ditch castable 12, and there is a slag-iron mixture 11 in the large ditch surrounded by the iron ditch castable 12, and the lower part of the iron ditch castable 12 is connected with iron Ditch material or pre-cast iron ditch permanent layer 14, main ditch steel s...

Embodiment 2

[0036] Embodiment 2: A method for installing and using water-cooled devices in the main ditch of a blast furnace tapping ditch; it includes the steps of making the cooler, installing it, and pouring it,

[0037] Cooler manufacturing steps: first use metal seamless pipes as cooling water pipes 4, process them into circular rotary devices by filling sand with hot bending, and then fix the bent metal seamless pipes to the cavity made of steel plates On the surface of the structure, metal ceramics are used to cast the protective layer of metal seamless pipes by casting;

[0038] The structure of the main ditch water cooler is completed. After the cermet is solidified, it will be dried at a temperature above 500°C, and the free water in the cermet will be removed before being transported to the site for installation;

[0039] Installation steps: Remove the materials in the original iron ditch during installation, then fix the cooler in the ditch, and install the inner mold for iron...

Embodiment 3

[0046] Embodiment 3: as figure 1 , figure 2 , image 3 As shown in Fig. 1, a water-cooling device for the main channel of a blast furnace tapping channel, its core is designed with a cavity structure, a seamless metal tube bending pipeline, and a protective layer made of cermets is attached to the metal pipeline.

[0047] The thickness of a single stave of the cooler is 400-600mm, the height is 600-1200mm, and the length is 1000-2000mm. The actual size is related to the size of the big ditch and the size of the blast furnace.

[0048] The seamless pipe used in the cooler is a 1-3 inch seamless pipe, which is bent by a hot bending process to form a rotary channel.

[0049] The cermet material covering the metal seamless pipe is composed of alumina particles and fine powder, corundum particles and fine powder, binder, steel fiber, and mixed into the mold by mechanical stirring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com