A gold@zinc oxide core-shell heterojunction thin film and its preparation method and application

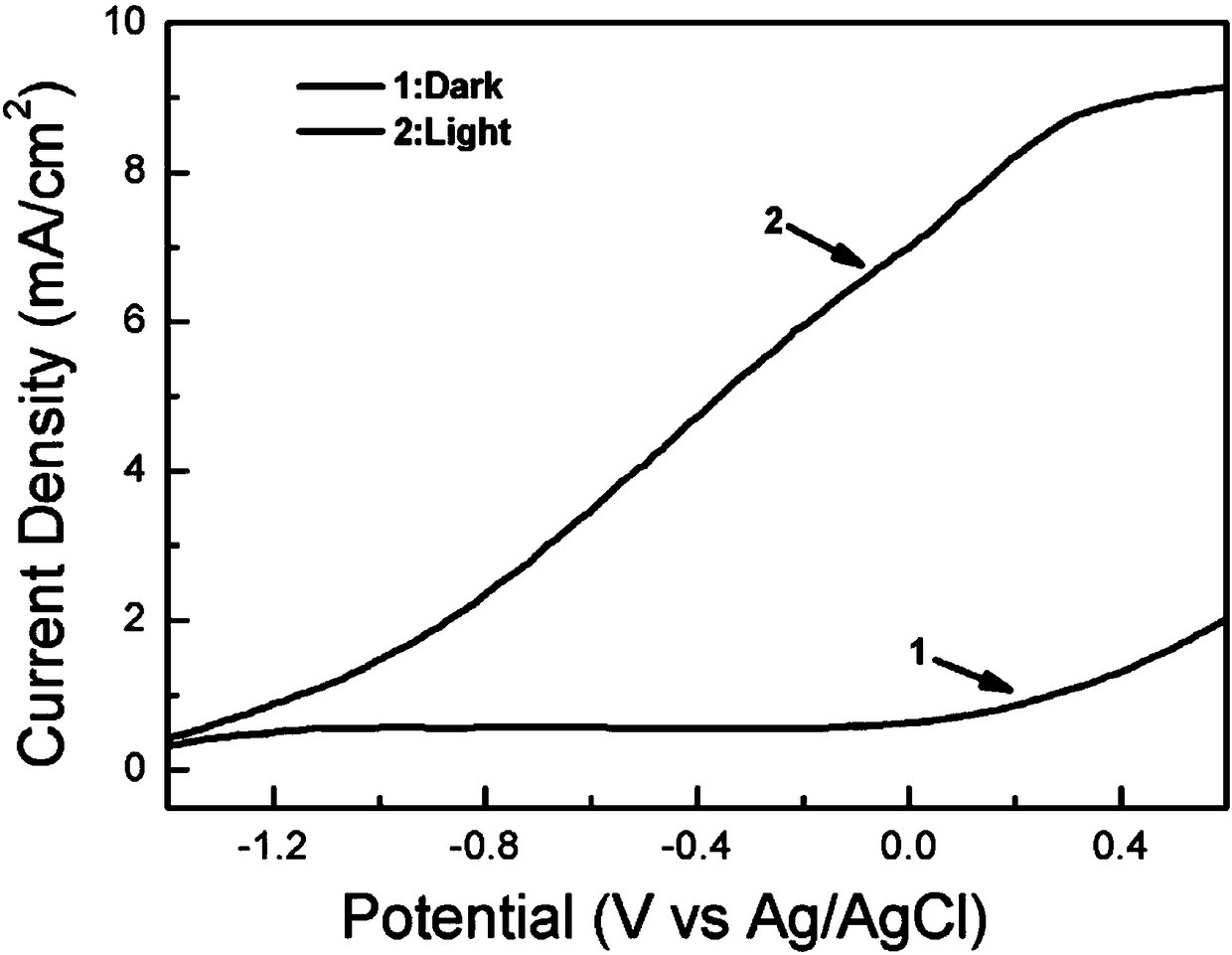

A heterojunction, core-shell technology, applied in the direction of metal processing equipment, electrodes, coatings, etc., can solve the problems of reduced catalytic reaction efficiency, achieve good photoelectric stability, excellent photoelectrochemical hydrogen production capacity, solve the problem of ultraviolet light and The effect of catalytic reaction efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

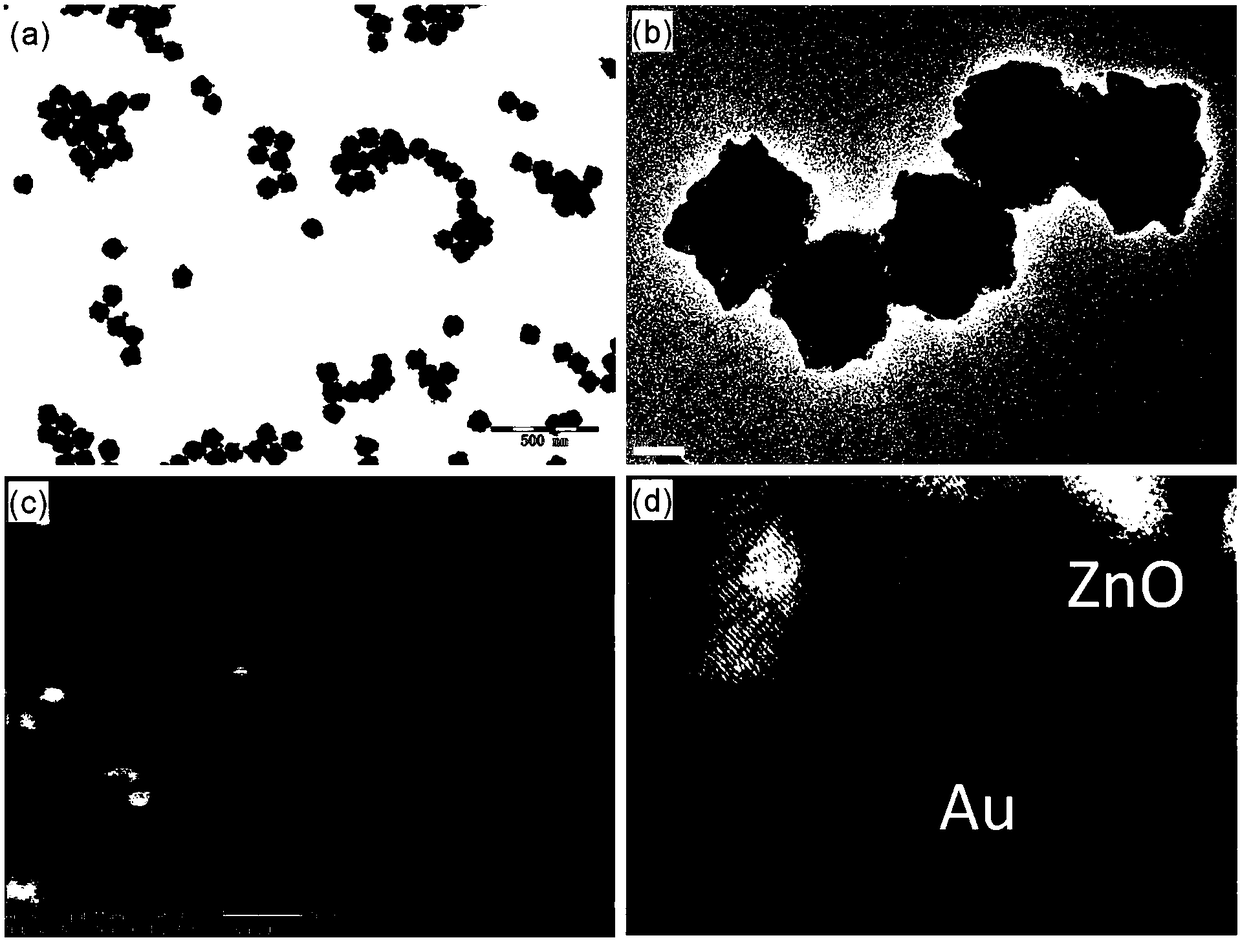

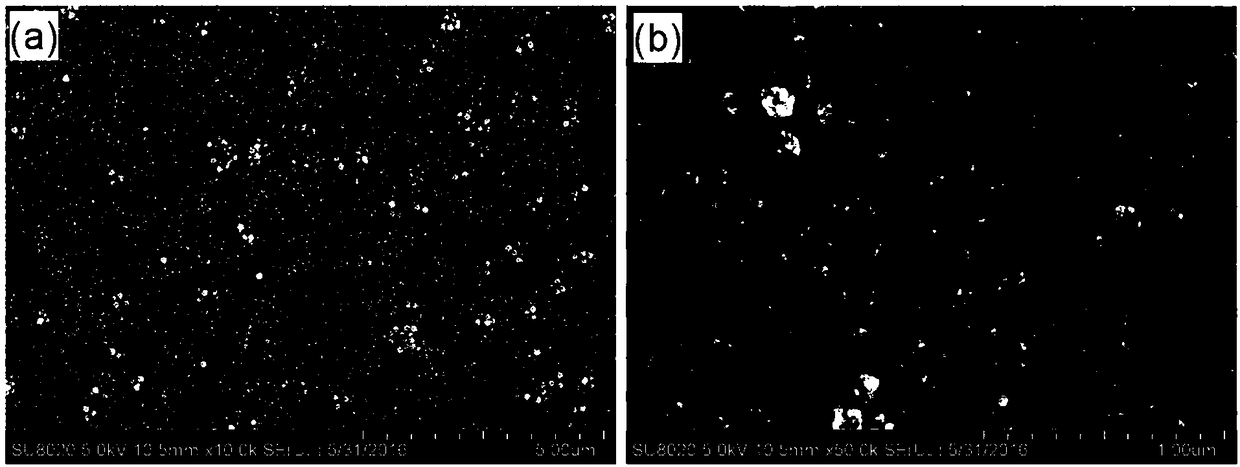

[0033] A gold@zinc oxide core-shell heterojunction thin film, the preparation method of which comprises the following steps:

[0034] Step A, disperse the gold@zinc oxide core-shell heterogeneous composite nanoparticles into the ethanol solution, and add dodecanethiol under stirring state (for example: under magnetic stirring state), so that dodecanethiol in the mixed liquid The concentration is 5-30 mmol / L, and then stand in the air for 10-30 minutes (preferably 15 minutes), so as to prepare the ethanol dispersion of surface-hydrophobic gold@zinc oxide core-shell heterogeneous composite nanoparticles.

[0035]Specifically, the treatment of dodecanethiol can make the gold@zinc oxide core-shell heterogeneous composite nanoparticles have good surface hydrophobic properties, which is conducive to the preparation of gold@zinc oxide core-shell heterogeneous composite nanoparticles through the gas-liquid interface self-assembly method. Thin film. The gold@zinc oxide core-shell hete...

Embodiment 1

[0051] A gold@zinc oxide core-shell heterojunction thin film, the preparation method of which comprises the following steps:

[0052] Step a1, adding a diethylene glycol diacrylate aqueous solution (the relative molecular weight of the diethylene glycol diacrylate is 100,000 to 200,000) with a mass concentration of 20% purchased on the market into the ethyl alcohol diol solution, and stir evenly, so as to obtain the ethylene glycol solution of diethylene glycol diacrylate phthalate; then add gold chloride to the ethylene glycol solution of diethylene glycol diacrylate phthalate Acid aqueous solution, so that the concentration of diethylene glycol diacrylate in the mixed liquid is 0.025 mole / liter, and the concentration of chloroauric acid is 0.0005 mole / liter, thereby obtaining the reaction precursor of gold octahedral nanoparticles.

[0053] Step b1, reacting the reaction precursor of the gold octahedral nanoparticles at 220° C. for 30 minutes to prepare a colloidal solution ...

Embodiment 2

[0060] A gold@zinc oxide core-shell heterojunction thin film, the preparation method of which comprises the following steps:

[0061] Step a2, adding a diethylene glycol diacrylate aqueous solution (the relative molecular weight of the diethylene glycol diacrylate is 100000 to 200000) purchased on the market with a mass concentration of 20% into the ethyl alcohol diol solution, and stir evenly, so as to obtain the ethylene glycol solution of diethylene glycol diacrylate phthalate; then add gold chloride to the ethylene glycol solution of diethylene glycol diacrylate phthalate Acid aqueous solution, so that the concentration of diethylene glycol diacrylate in the mixed liquid is 0.025 mole / liter, and the concentration of chloroauric acid is 0.0005 mole / liter, thereby obtaining the reaction precursor of gold octahedral nanoparticles.

[0062] Step b2, reacting the reaction precursor of the gold octahedral nanoparticles at 220° C. for 30 minutes to prepare a colloidal solution of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com