A kind of nano artificial leather and preparation method thereof

A kind of artificial leather and nano technology, which is applied in the field of nano artificial leather and artificial leather preparation, and can solve the problems of fast wear and poor folding resistance of artificial leather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

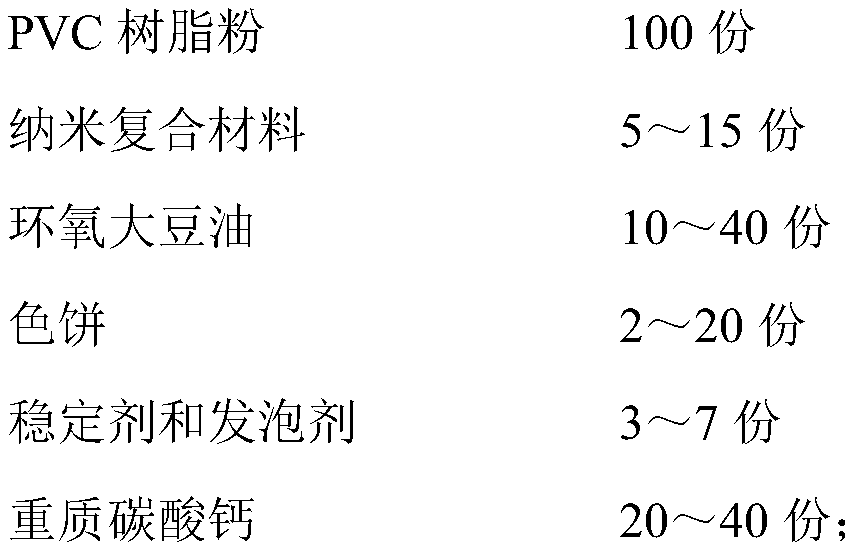

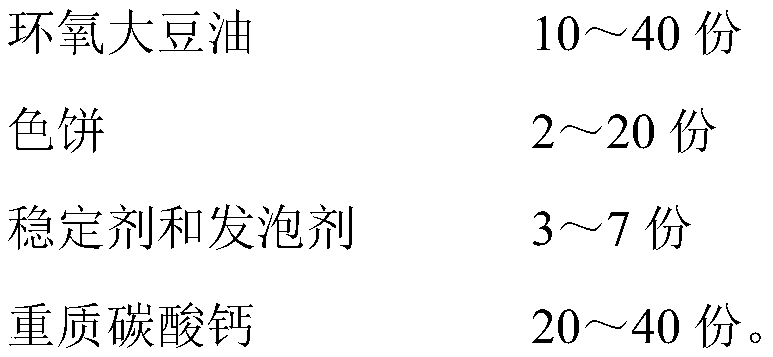

[0019] The raw materials of the high-strength slurry and their weight ratios are: 100 parts of PVC resin powder, nano-titanium dioxide and nano-silica composite material (1:1, average particle size 20nm; specific surface area ≥ 50m 2 / g) 14 parts, 30 parts of epoxidized soybean oil, 7 parts of color cake, 2 parts of potassium zinc stabilizer, 2 parts of foaming agent, 30 parts of heavy calcium.

[0020] According to the ingredients, the above-mentioned materials measured are input into the high-speed mixer through the pulse feeder, and the temperature is controlled at 100-150 ° C. After fully stirring, they enter the internal mixer, and the temperature is controlled at (160 ° C) for several minutes; After the base material (various fabrics) is opened, apply PU slurry (150°C), combine the fully mixed material with the base material with PU slurry, enter the second rolling mill (160°C) for kneading, and then After entering the four-roll calender (temperature 160-190 ℃) and calen...

Embodiment 2

[0024] The raw materials of the high-strength slurry and their weight ratios are: 100 parts of PVC resin powder, nano-titanium dioxide and nano-silica composite material (1:1.2, average particle size 20nm; specific surface area ≥ 50m 2 / g) 13 parts, 31 parts of epoxidized soybean oil, 7 parts of color cake, 2 parts of potassium zinc stabilizer, 2 parts of foaming agent, 35 parts of heavy calcium. The preparation method is the same as in Example 1.

[0025] This artificial leather physical and chemical property is as follows: stripping load 17N; Warp tensile load 228N; Weft tensile load 159N; Warp tear load 20N; Weft tear load 16N; 23°C, 100,000 cycles -10°C, 35,000 cycles) No cracks on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com