Large-temperature-difference heat exchange device for Freon

A heat exchange device and freon technology, applied in the thermal field, can solve problems such as insufficient heat supply, and achieve the effects of reducing high energy consumption, improving heat quality, and improving scientific adjustment capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

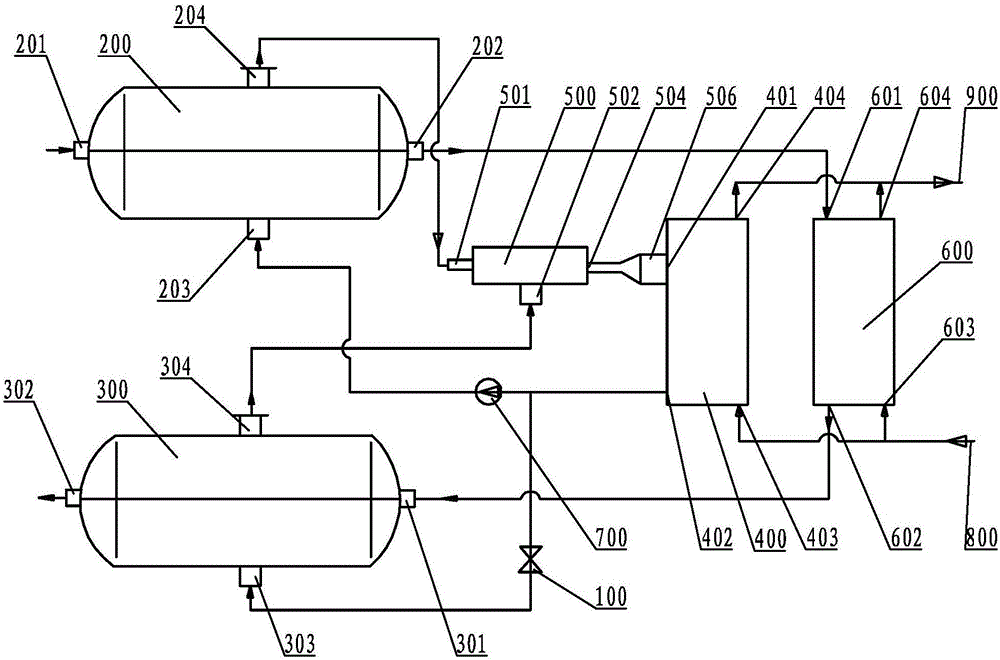

[0028] Specific implementation mode one: combine figure 1Describe this embodiment. This embodiment includes a high-temperature evaporator 200, a low-temperature evaporator 300, a condenser 400, an injector 500, a heat exchanger 600, a throttle valve 100, a Freon pump 700, and a high-temperature water outlet 202 of the high-temperature evaporator 200. It is connected to the heat exchanger water inlet 601 of the heat exchanger 600, the heat exchanger water outlet 602 of the heat exchanger 600 is connected to the low temperature water inlet 301 of the low temperature evaporator 300, and the high temperature water inlet 201 of the high temperature evaporator 200 is connected to the heat network. The water pipe connection, the low temperature water outlet 302 of the low temperature evaporator 300 is connected with the return pipe of the heating pipe network, the high temperature freon steam outlet 204 of the high temperature evaporator 200 is connected with the drive steam inlet 501...

specific Embodiment approach 2

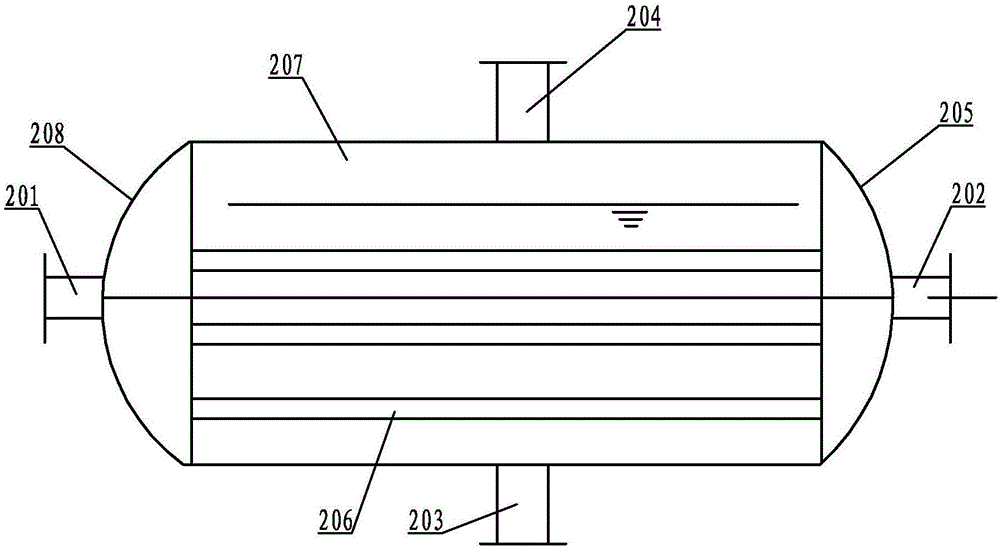

[0029] Specific implementation mode two: combination figure 2 To illustrate this embodiment, the high-temperature evaporator 200 of this embodiment is a horizontal pressure vessel, and its composition includes a high-temperature water inlet 201, a high-temperature water outlet 202, a high-temperature Freon liquid inlet 203, a high-temperature Freon steam outlet 204, a high-temperature right Head 205, high-temperature cylinder 207, high-temperature left head 208 and multiple high-temperature heat transfer tubes 206, high-temperature cylinder 207 is arranged horizontally, the left end of high-temperature cylinder 207 is connected with high-temperature left Connected with the high-temperature right head 205, a plurality of high-temperature heat transfer tubes 206 are arranged horizontally in the high-temperature cylinder 207, the high-temperature water inlet 201 is arranged on the high-temperature left head 208, and the high-temperature water outlet 202 is arranged on the high-te...

specific Embodiment approach 3

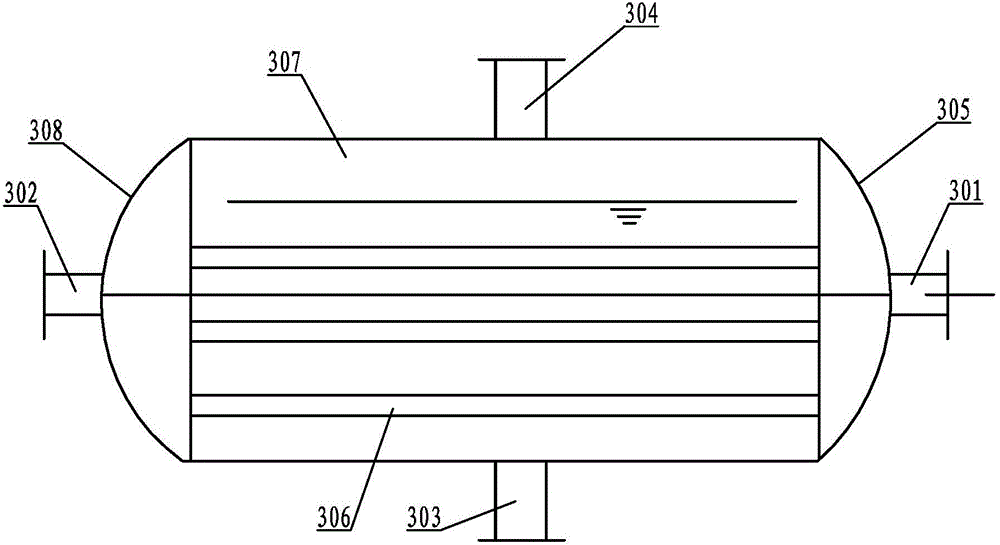

[0030] Specific implementation mode three: combination image 3 Describe this embodiment, the low-temperature evaporator 300 of this embodiment is a horizontal pressure vessel, and its composition includes a low-temperature water inlet 301, a low-temperature water outlet 302, a low-temperature Freon liquid inlet 303, a low-temperature Freon steam outlet 304, a low-temperature right Head 305, low-temperature cylinder body 307, low-temperature left cylinder head 308 and multiple low-temperature heat transfer tubes 306. The low-temperature cylinder body 307 is arranged horizontally. Connected with the low-temperature right head 305, the low-temperature cylinder 307 is horizontally provided with a plurality of low-temperature heat transfer tubes 306, the low-temperature water outlet 302 is arranged on the low-temperature left head 308, and the low-temperature water inlet 301 is arranged on the low-temperature right head 305. The low-temperature Freon steam outlet 304 is arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com