Active disturbance rejection control method for a rodless cylinder position servo system

A technology of active disturbance rejection control and servo system, applied in the direction of adaptive control, controller with specific characteristics, electric controller, etc., to achieve the effect of simple controller structure, convenient parameter setting, fast and precise position control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

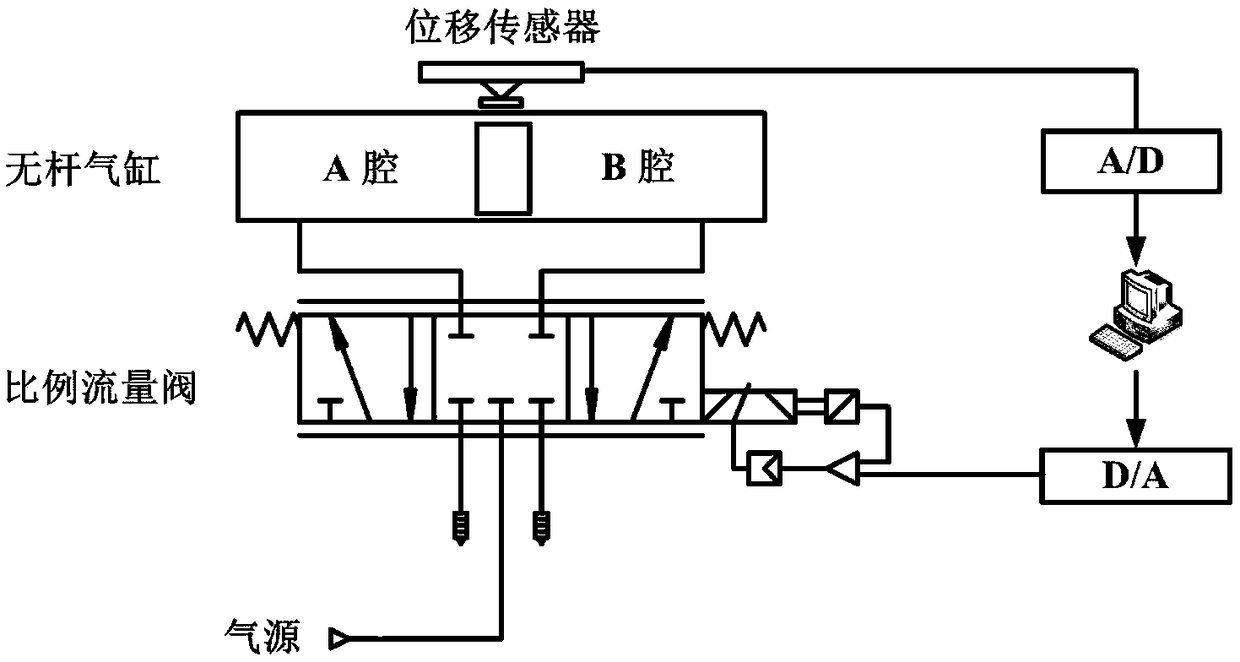

[0094] The components of the rodless cylinder pneumatic servo system are: CY1H rodless cylinder produced by SMC company, MPYE proportional directional control valve produced by FESTO company, grating displacement sensor, Advantech industrial computer, analog output board, data acquisition board cards, air compressors, etc.

[0095] The control target is set to

[0096] Reference input signal: v 0 = 100mm step signal;

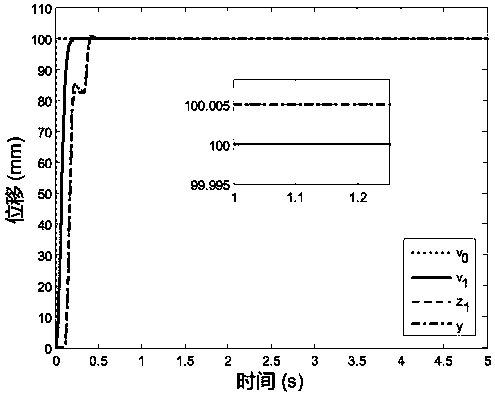

[0097] When a step signal v is given 0 =100mm, the system displacement output curve is as follows image 3 shown. where v 0 is the reference input signal, v 1 is the reference input signal v 0 tracking signal, z 1 Outputs the observed value of y for the system. It can be seen from the figure that the system output y can quickly and accurately track the upper reference input signal v 0 , and z 1The system displacement output y can be well observed.

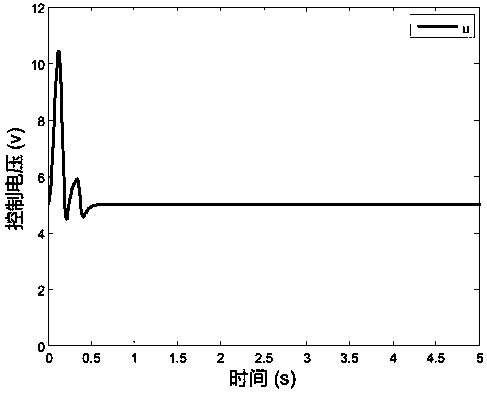

[0098] In a pneumatic servo system, the control input signal is a voltage signal. Figure 4 Shown is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com