Transition loading plate device, display panel and manufacture method, minisize light-emitting member detection method

A manufacturing method and technology of light-emitting parts, which are applied in the direction of single semiconductor device testing, semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, etc., and can solve the problem of small size, excessively large probe size, and damage to micro-luminous light by probes Problems such as diodes to achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

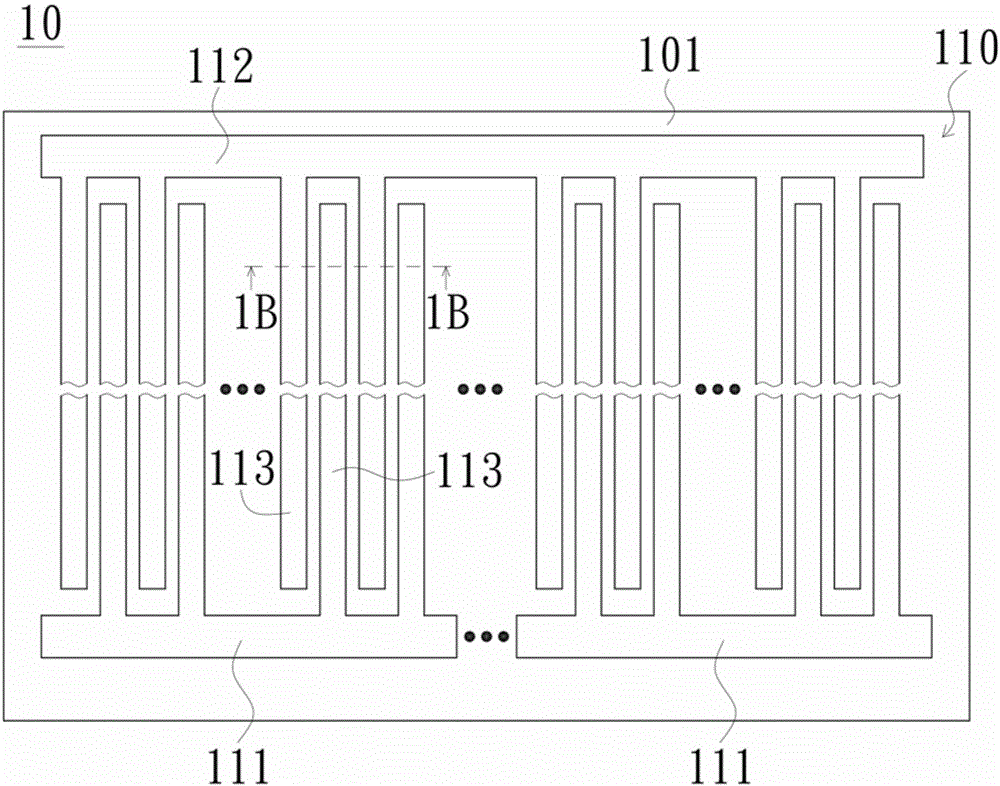

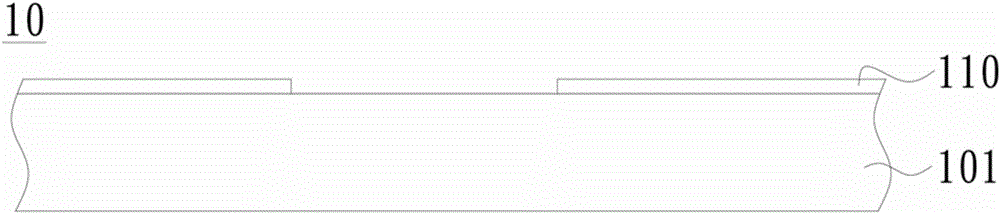

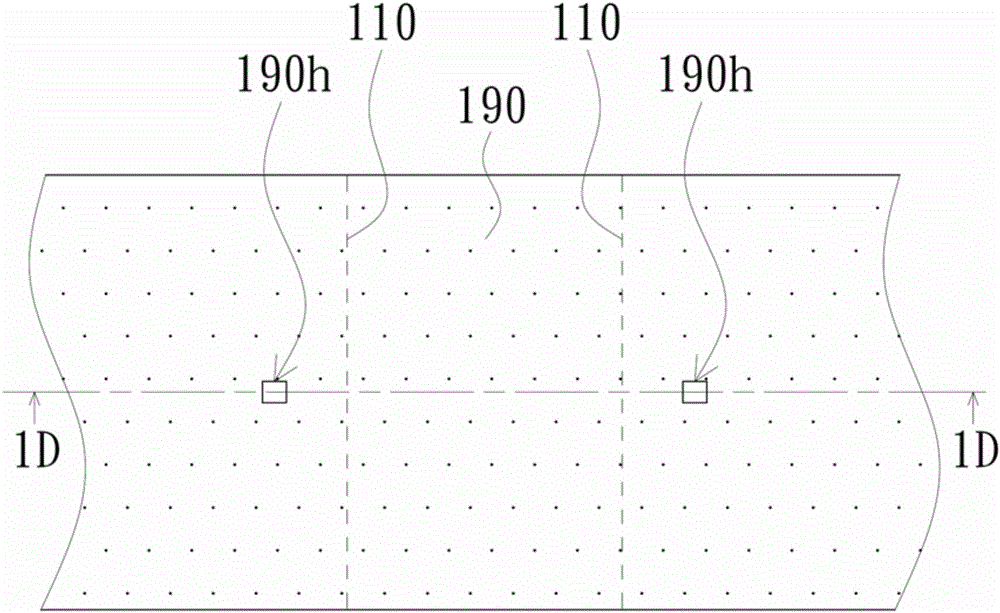

[0075] Figure 1A , Figure 1B , Figure 1C , Figure 1D , Figure 1E , Figure 1F , Figure 1G , Figure 1H , Figure 1I , Figure 1J , Figure 1K , Figure 1L , Figure 1M , Figure 1N and Figure 1O is a schematic diagram of a method for manufacturing a transition carrier device according to an embodiment of the present invention. see Figure 1A and Figure 1B , in the manufacturing method of the transition carrier device, firstly, the wiring layer 110 is formed on the substrate 101 to form the transition carrier 10 including the substrate 101 and the wiring layer 110 . Figure 1A shows a top view of the transition carrier 10, and Figure 1B for Figure 1A The cross-sectional view drawn along the line 1B-1B in the center.

[0076] The substrate 101 is preferably a rigid substrate, such as a glass plate or a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com