Preparation method of Pt-Cu linear nano-catalyst

A nano-catalyst and wire-shaped technology, which is applied in the field of preparation of Pt-Cu wire-shaped nano-catalysts, can solve the problems of unguaranteed yield, small long diameter, long preparation cycle, etc., achieve broad application prospects, and the method is simple and easy line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

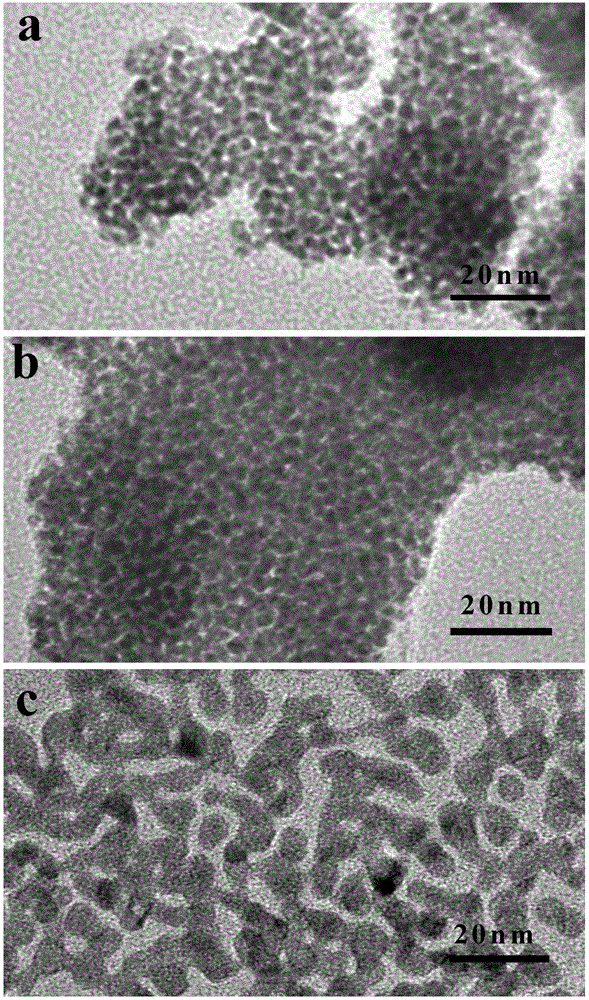

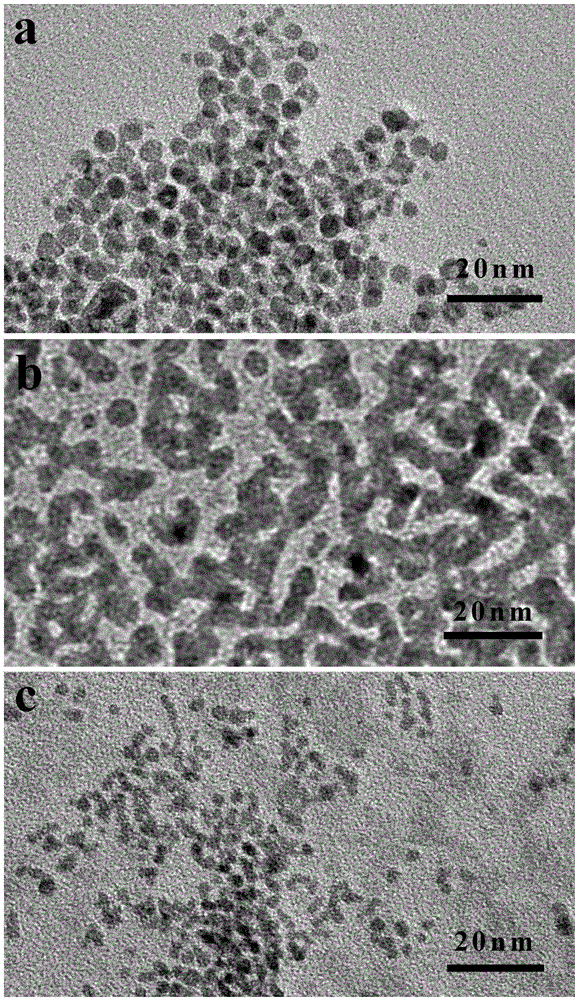

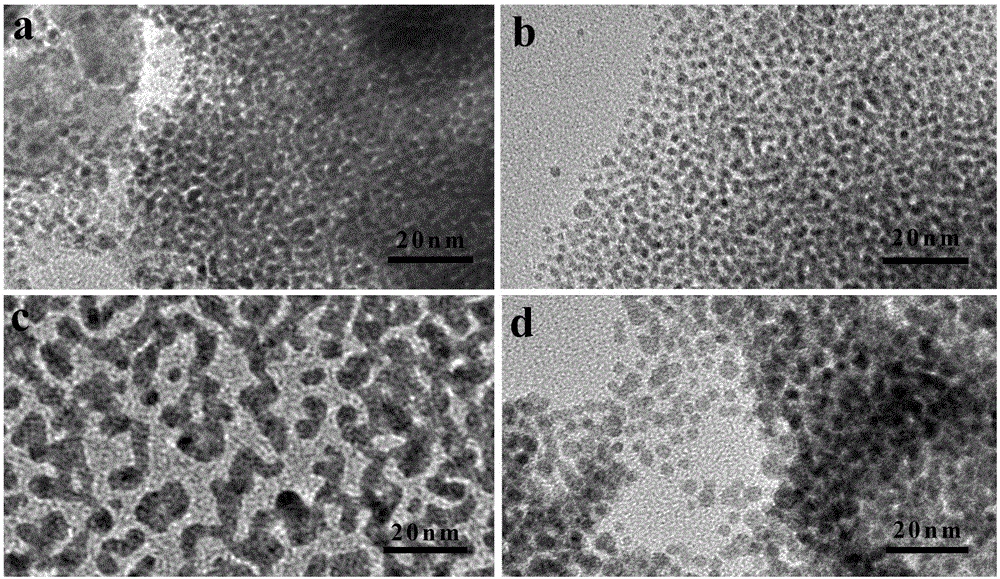

Embodiment 1

[0033] 1. At room temperature, add 5ml of oleylamine to the reaction kettle.

[0034] 2. At room temperature, 0.01g of platinum acetylacetonate (Pt(acac) 2 , 2.54×10 -5 mol) and 0.05g potassium iodide (1.51×10 -4 mol) into 5ml oleylamine, magnetically stirred for 30min, then added 0.02g copper acetylacetonate (Cu(acac) 2 , 7.64×10 -5 mol), and magnetically stirred for 10 min.

[0035] 3. Tighten the reactor and put it in the oven, set the oven temperature to 170°C, and the reaction time to 12 hours.

[0036] 4. After the reaction is finished, wash with absolute ethanol for 4 times to obtain the Pt-Cu linear nanocatalyst.

experiment example 2

[0038] Other experimental steps are the same as in Experimental Example 1, except that the amount of KI in step 2 is changed from 0.05 g to 0 g.

experiment example 3

[0040] Other experimental steps are the same as in Experimental Example 1, except that the amount of KI in step 2 is changed from 0.05g to 0.025g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com