Rapid densifying method for powder high-temperature alloy component

A superalloy and densification technology, which is applied to the improvement of the preparation process of powder superalloy components and the field of rapid densification, can solve the problems of complex process, difficult process execution and structure control, and narrow processing window, so as to reduce the manufacturing cost and shorten the The effect of development cycle and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

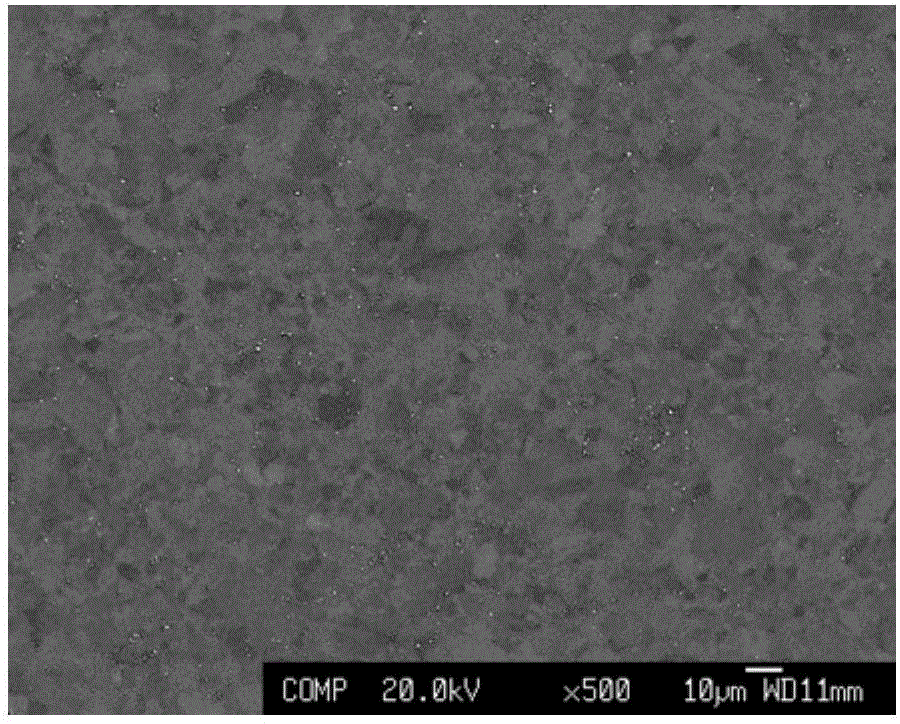

Embodiment 1

[0030] The rapid prototyping method for powder superalloy components is characterized in that: the steps of the method are:

[0031] Step 1. Preparation of powder billet

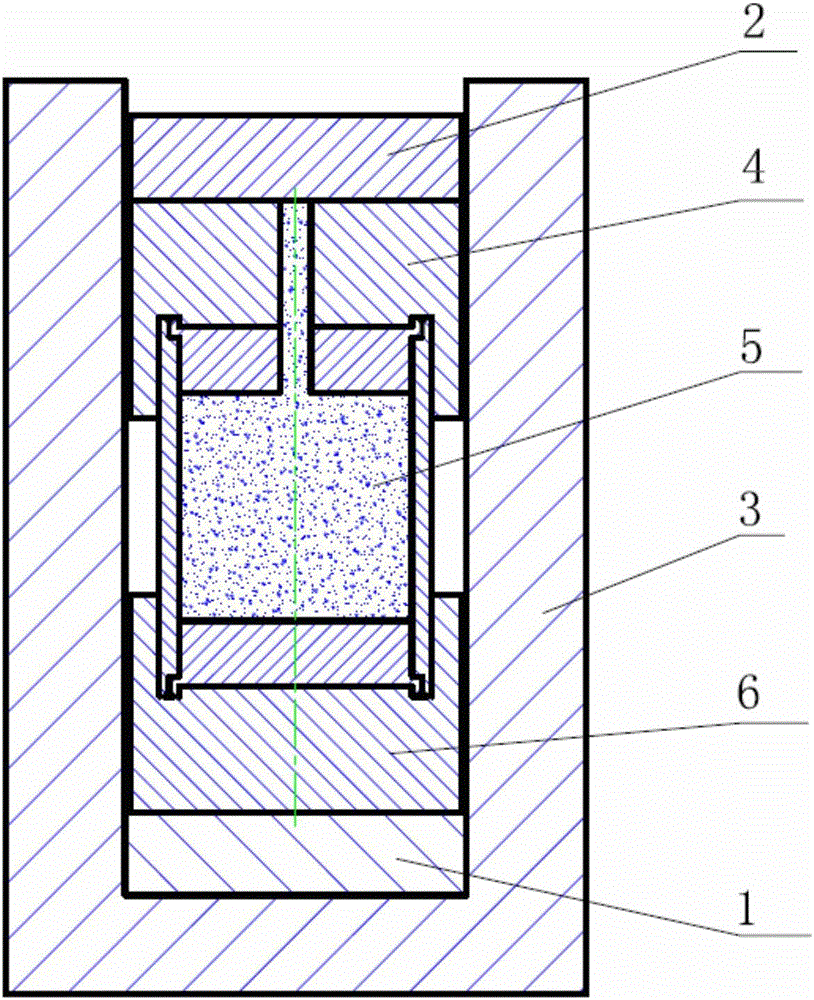

[0032] According to the calculation of the volume of the component, a cylindrical stainless steel sheath is made, the grade of the stainless steel material is 304, the superalloy powder is filled in the sheath, the inside of the sheath is vacuumed and then sealed and welded to obtain a cylindrical powder ingot 5. The upper end of the powder ingot 5 is connected by welding to an upper end cover 4 for protecting the powder inlet pipe of the sheath, and the lower end of the powder ingot 5 is connected by welding to a lower end cover 6 that matches the shape of the upper end cover 4 so that the sheath is evenly pressed ;

[0033] Step 2. Preparation of forging mold

[0034] The forging mold is prepared by adopting a steel material with a fracture strength exceeding 2000MPa, and the forging mold is composed of ...

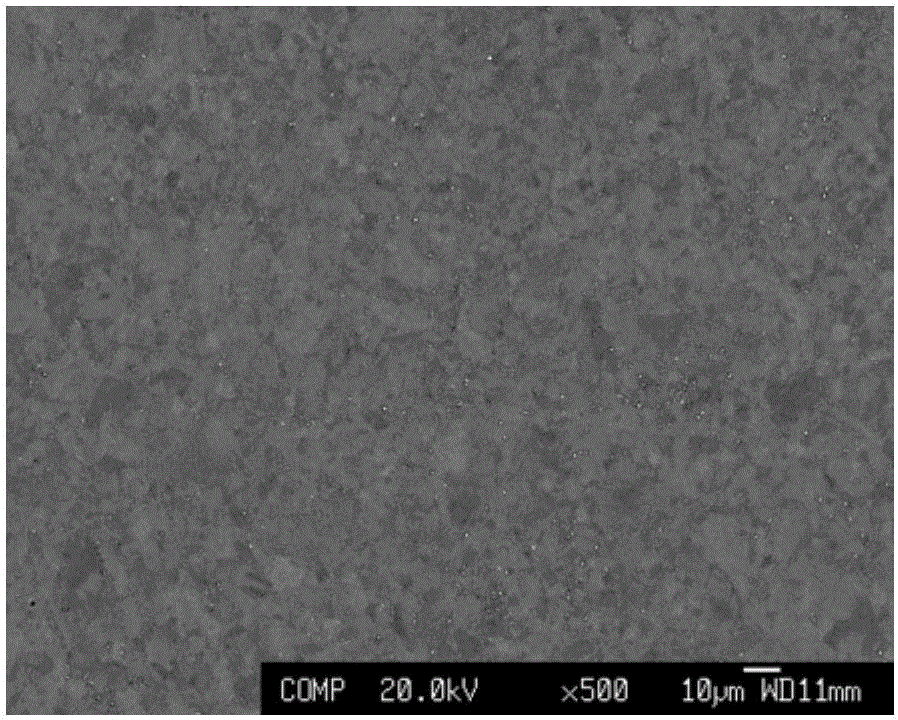

Embodiment 2

[0044] The rapid prototyping method for powder superalloy components is characterized in that: the steps of the method are:

[0045] Step 1. Preparation of powder billet

[0046] According to the calculation of the volume of the component, a cylindrical stainless steel sheath is made, the grade of the stainless steel material is 304, the superalloy powder is filled in the sheath, the inside of the sheath is vacuumed and then sealed and welded to obtain a cylindrical powder ingot 5. The upper end of the powder ingot 5 is connected by welding to an upper end cover 4 for protecting the powder inlet pipe of the sheath, and the lower end of the powder ingot 5 is connected by welding to a lower end cover 6 that matches the shape of the upper end cover 4 so that the sheath is evenly pressed ;

[0047] Step 2. Preparation of forging mold

[0048]The forging mold is prepared by adopting a steel material with a fracture strength exceeding 2000MPa, and the forging mold is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com