A boarding bridge device for vehicle-mounted remote control non-road walking equipment

A technology of walking equipment and boarding bridge, which is applied in the field of loading and unloading and transportation of special equipment, can solve the problems of falling damage, long length of boarding bridge, self-heaviness, etc., and achieve the goals of preventing damage from falling, reducing the number and improving the supporting strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

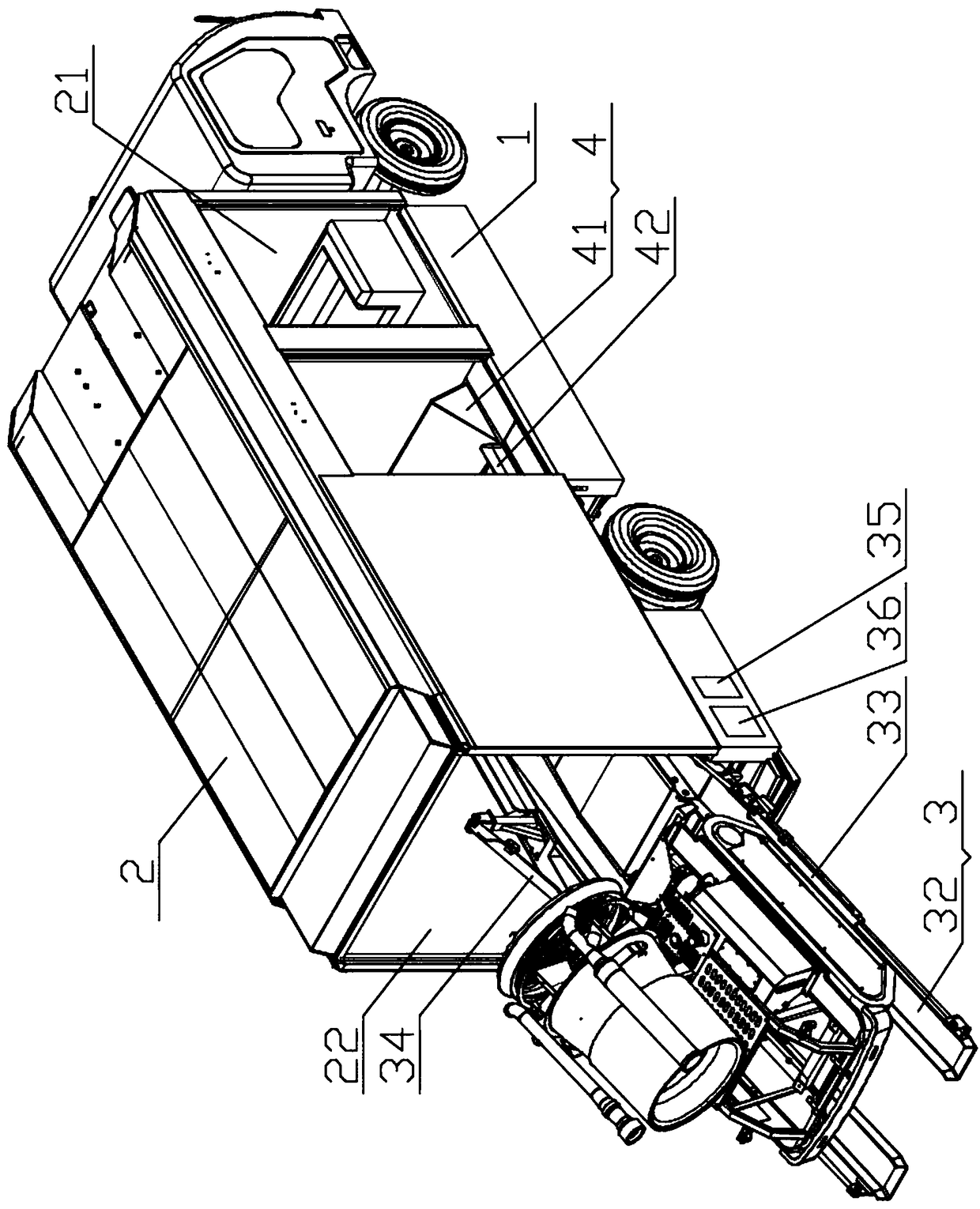

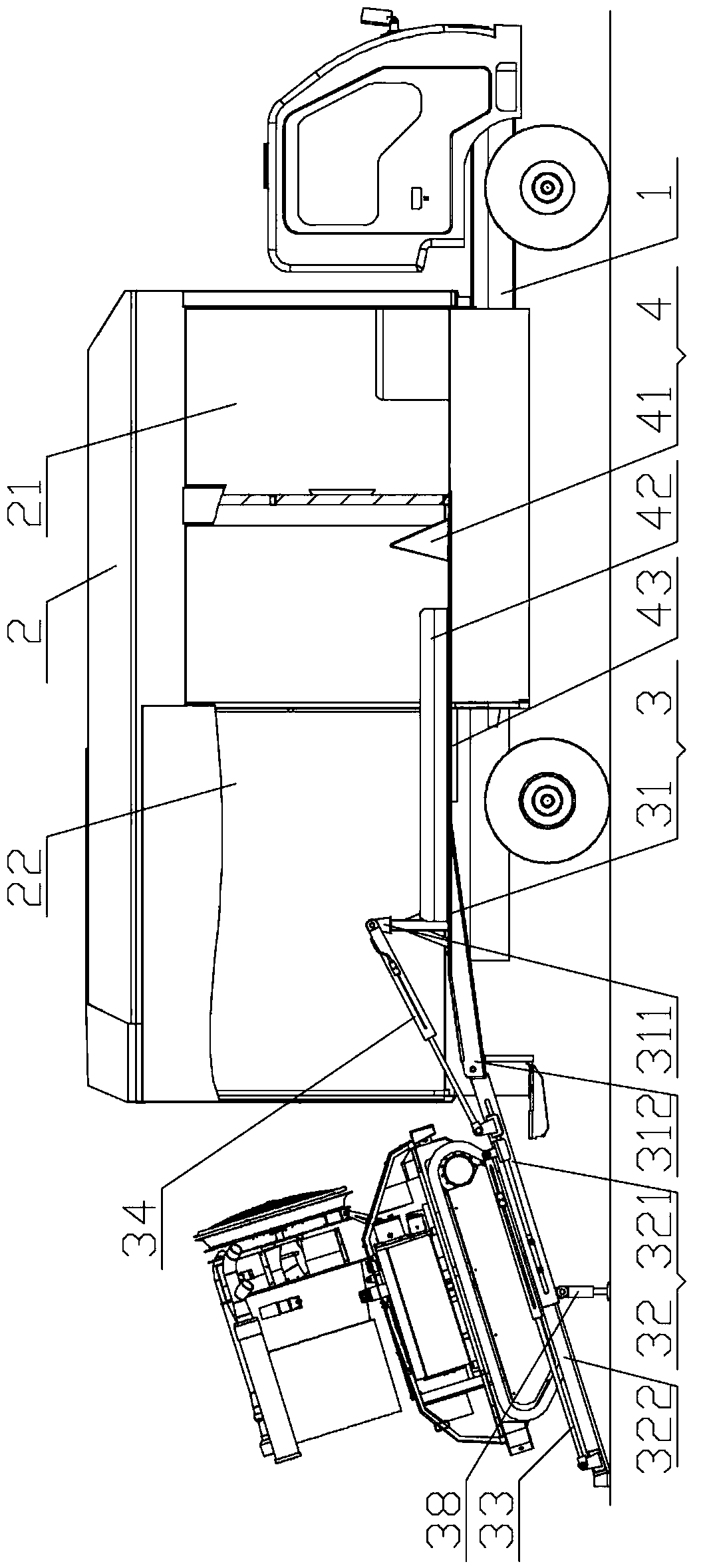

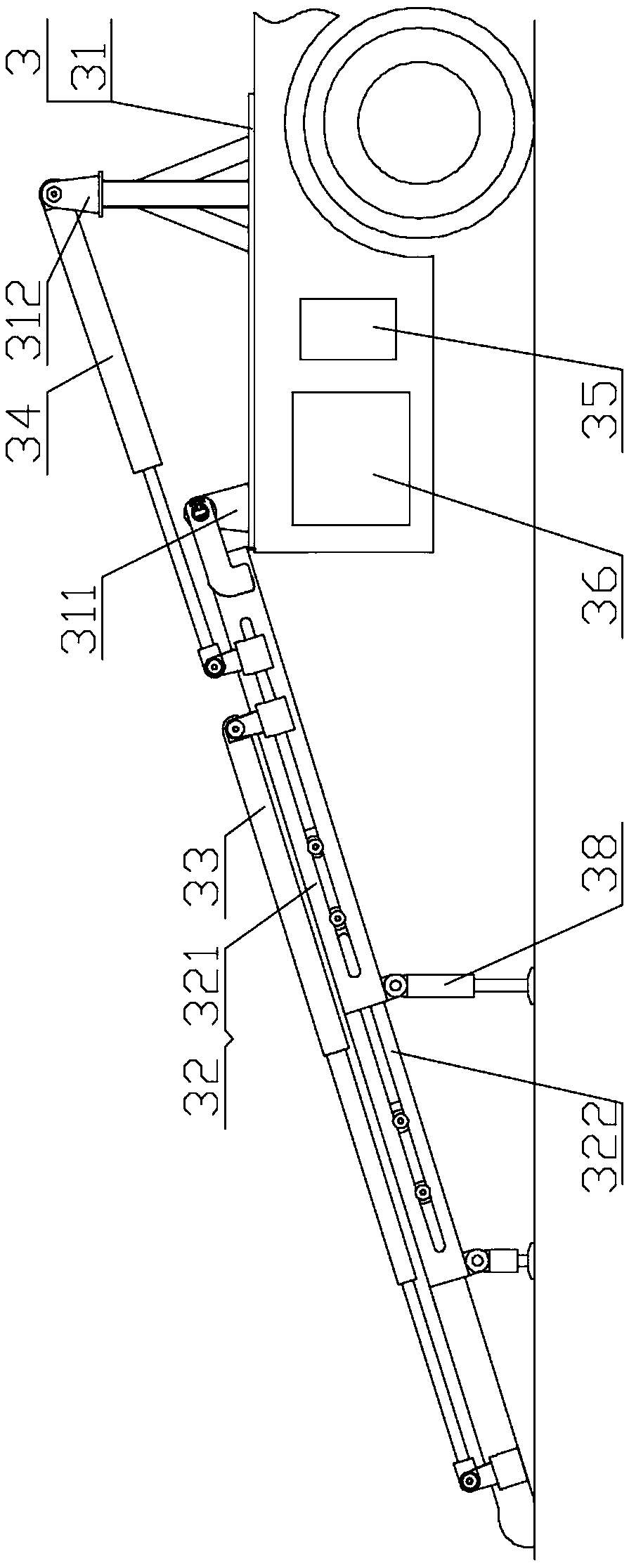

[0024] Take the fire-fighting robot and the fire-fighting command comprehensive operation vehicle as example below, and the state that the boarding bridge device of this vehicle-mounted remote control non-road surface walking equipment is fully expanded in conjunction with the accompanying drawings will further illustrate the present invention (the normal driving of the fire-fighting command comprehensive operation vehicle below) directions are described above).

[0025] Such as figure 1 , figure 2 As shown, the integrated fire control operation vehicle includes a car body chassis 1, a compartment 2, a boarding bridge device 3 and a fire robot positioning device assembly 4.

[0026] The compartment 2 is a closed structure comprising a compartment floor, the front portion of the compartment 2 is provided with a fire-fighting robot command room 21, and the fire-fighting robot command room 21 is provided with a fire-fighting robot monitoring system including a monitoring screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com