SPEEK spontaneous asymmetric gas component adjustment film and its preparation method and use

A gas composition, asymmetric technology, applied in the field of membrane materials, can solve the problems of difficult film forming, insoluble, high melting point, etc., and achieve the effect of improving film forming conditions, low cost and high separation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Take 200mL concentrated H 2 SO 4 and 10g of PEEK, stirred at 300r / min and 60°C for 5h to obtain a crude product, which was washed with 1000 times the mass of water, and then dried at 60°C for 24h to obtain sulfonated polyether ether ketone (SPEEK), with a yield of 13.2g, the degree of sulfonation (DS) is 62.3%;

[0040] (2) Add SPEEK to DMF after pulverization, magnetically stir at 60°C and 500r / min for 2h until completely dissolved, cool for later use, and obtain a casting solution with a concentration of 1g / 10mL;

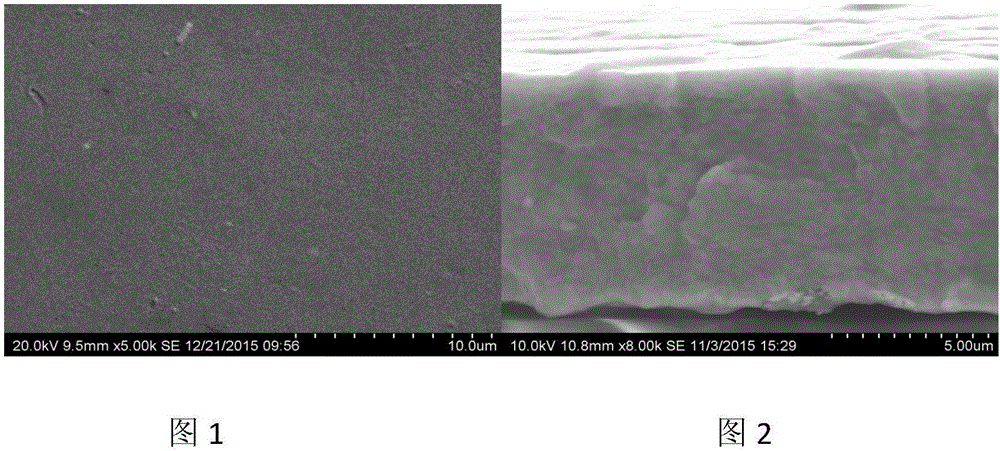

[0041] (3) Cast the film casting solution obtained in step (2) on a clean glass plate to form a film with a film thickness of 50 μm, then put it in an oven and dry it at 60°C for 12 hours, cool it to room temperature naturally, and immerse it in distilled water at room temperature , taken out, and dried at room temperature to obtain the SPEEK spontaneous asymmetric gas composition adjustment membrane.

Embodiment 2

[0043] (1) Take 200mL concentrated H 2 SO 4 and 10g of PEEK, stirred at 300r / min and 60°C for 7h to obtain a crude product, washed with 1000 times the mass of water, and then dried at 60°C for 24h to obtain sulfonated polyether ether ketone (SPEEK), sulfonated Degree (DS) is 67.4%;

[0044] (2) Add SPEEK to DMF after pulverization, magnetically stir at 60°C and 500r / min for 2h until completely dissolved, cool for later use, and obtain a casting solution with a concentration of 1g / 10mL;

[0045] (3) Cast the film casting solution obtained in step (2) on a clean glass plate to form a film with a film thickness of 50 μm, then put it in an oven and dry it at 60°C for 12 hours, cool it to room temperature naturally, and immerse it in distilled water at room temperature , taken out, and dried at room temperature to obtain the SPEEK spontaneous asymmetric gas composition adjustment membrane.

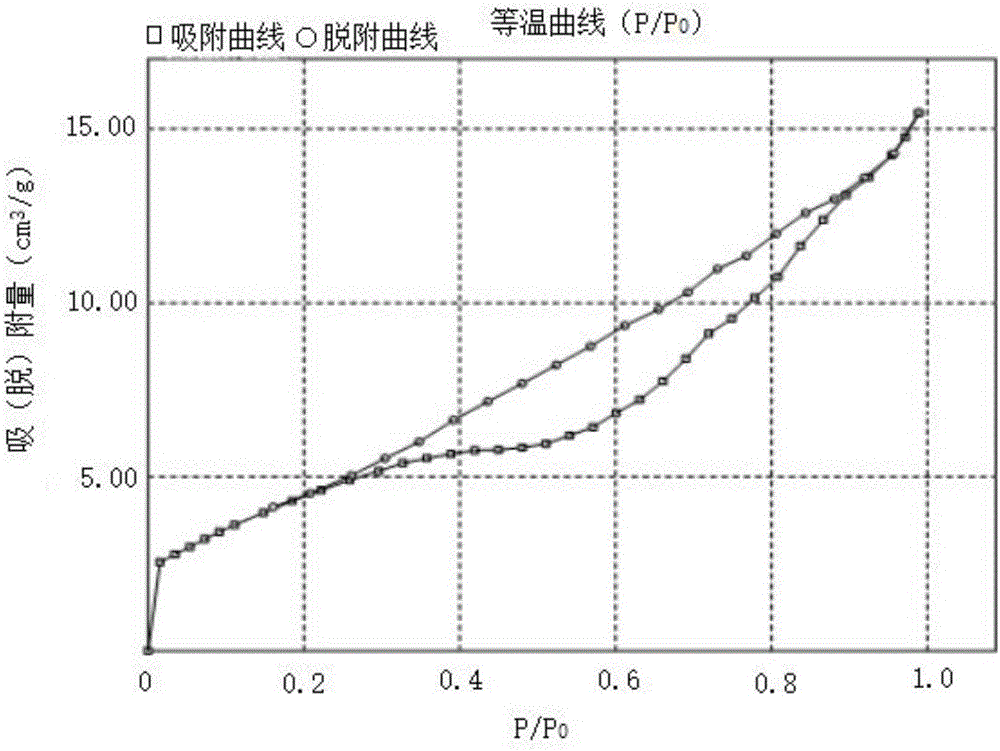

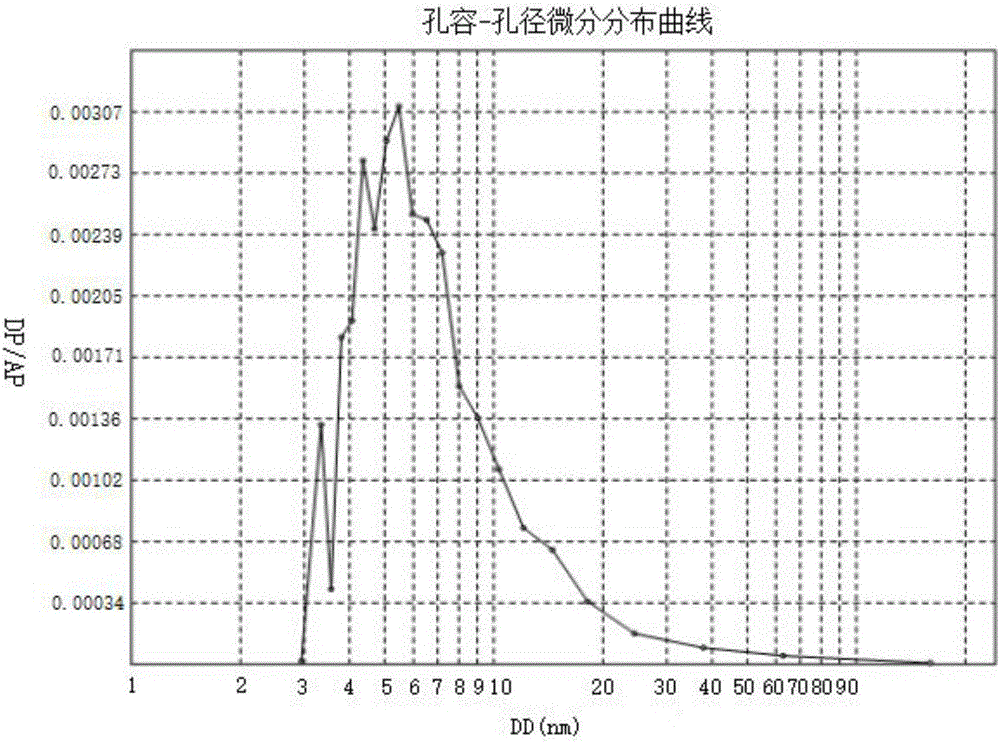

[0046] The specific surface area of the SPEEK spontaneous asymmetric gas composition a...

Embodiment 3

[0048] (1) Take 200mL concentrated H 2 SO 4 and 10g of PEEK, stirred at 300r / min and 50°C for 7h to obtain a crude product, washed with 1000 times the mass of water, and then dried at 60°C for 24h to obtain sulfonated polyether ether ketone (SPEEK), sulfonated The degree is (DS) 49.8%;

[0049] (2) Add SPEEK to DMF after pulverization, magnetically stir at 60°C and 500r / min for 2h until completely dissolved, cool for later use, and obtain a casting solution with a concentration of 1g / 10mL;

[0050] (3) Cast the film casting solution obtained in step (2) on a clean glass plate to form a film with a film thickness of 50 μm, then put it in an oven and dry it at 60°C for 12 hours, cool it to room temperature naturally, and immerse it in distilled water at room temperature , taken out, and dried at room temperature to obtain the SPEEK spontaneous asymmetric gas composition adjustment membrane.

[0051] The specific surface area of the SPEEK spontaneous asymmetric gas compositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com