CMR or CMP graded flame retardant cable material

A technology of flame retardant cable material and flame retardant, which can be used in plastic/resin/wax insulators, organic insulators, etc., and can solve problems such as the decline of flame retardant performance

Inactive Publication Date: 2017-02-08

余姚市楷瑞电子有限公司

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the addition of a large amount of plasticizers and other additives to PVC cable materials, the flame retardant performance is greatly reduced, and the oxygen index drops to about 24%.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

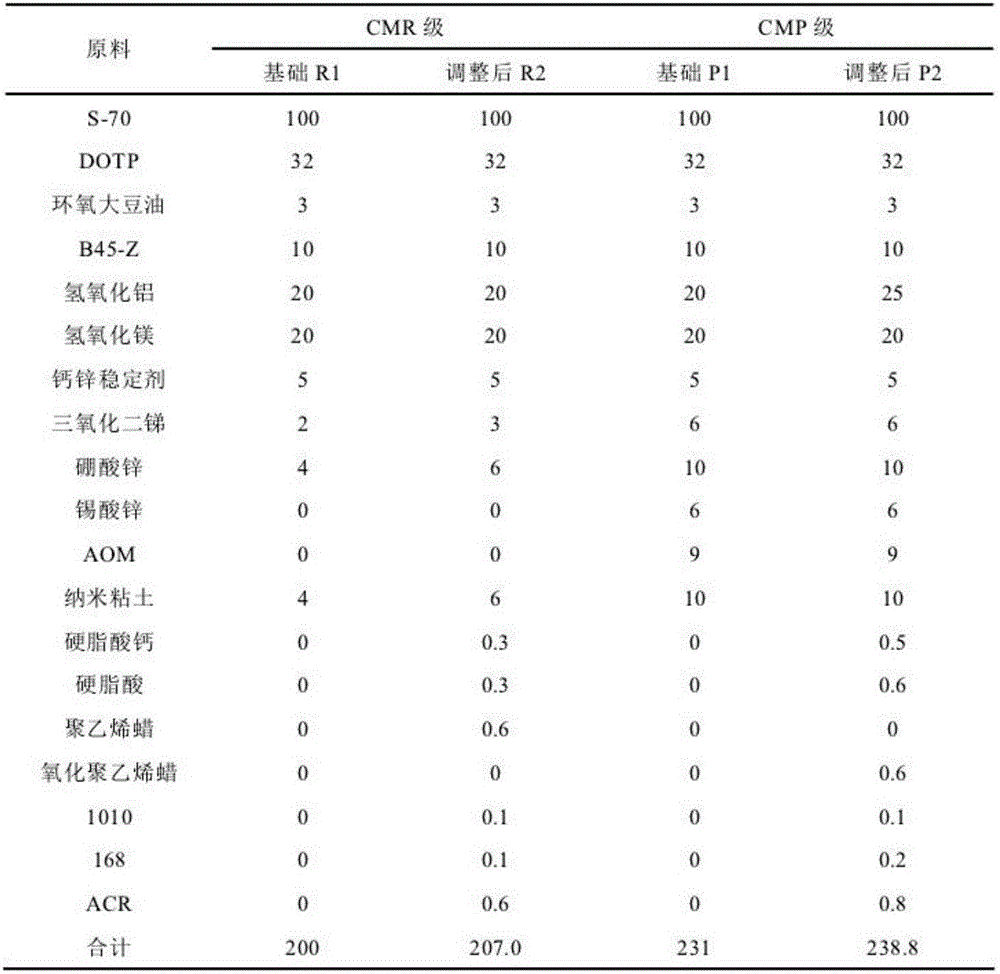

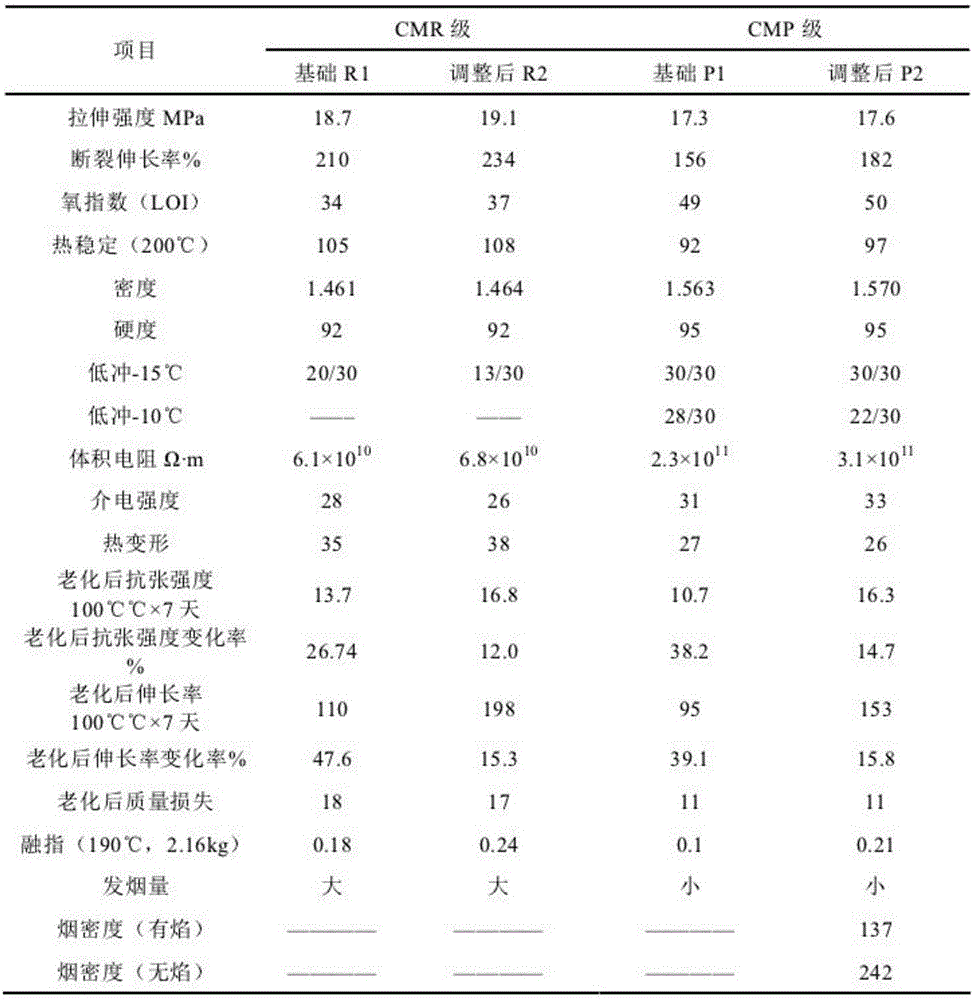

[0026] The samples of the examples were prepared according to the formula shown in the table below and according to the method described above. The properties were tested according to the following methods.

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a CMR or CMP graded flame retardant cable material including polyvinyl chloride, a tetrabromo phthalic anhydride ester-containing plasticizer, a first flame retardant, a second flame retardant, a calcium zinc stabilizer, a lubricant and a processing modifier, wherein based on 100 parts by weight of the polyvinyl chloride, the amount of the plasticizer is 30-50 parts by weight, the amount of the first flame retardant is 30-50 parts by weight, the amount of the calcium zinc stabilizer is 1-5 parts by weight, the amount of the second flame retardant is 10-40 parts by weight, the amount of the lubricant is 0.1-2 parts by weight, and the amount of the processing modifier is 0.1-1 part by weight; the first flame retardant is selected from a combination of aluminum hydroxide and magnesium hydroxide, the second flame retardant is selected from at least four of antimonous oxide, zinc borate, zinc stannate, ammonium octamolybdate and nano clay. The CMR or CMP graded flame retardant cable material has excellent comprehensive performance and processing performance.

Description

technical field [0001] The present invention relates to high-performance cables, and more particularly to CMR or CMP grade flame-retardant cable compounds for forming cable covering materials. Background technique [0002] After China's accession to the WTO, the standards established are basically in line with international standards, and the initial formulation of international cable standards is mostly from Europe, so it can be regarded as a system. The flame-retardant cable standard in the United States is formulated by the unofficial Underwriters Laboratories (UL), which requires flame-retardant cables to be divided into CMX, CM, CMR, and CMP from low to high. [0003] Compared with the European standard, the flame retardant cable standard in the United States adds higher grades of CMR and CMP, especially the highest flame retardant grade CMP (supercharged grade). In order to meet the requirements of this level, the selected polymer has relatively high requirements, or ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/06C08L91/00C08L23/06C08L23/30C08L33/04C08K5/12C08K3/22C08K3/38C08K3/34C08K5/098C08K5/09C08K5/134C08K5/526C08K3/24H01B3/44

CPCC08L27/06C08L2201/02C08L2203/202C08L2205/035H01B3/443C08L91/00C08L23/06C08L33/04C08K13/02C08K5/12C08K2003/2227C08K2003/2224C08K3/2279C08K2003/387C08K3/346C08K5/098C08K5/09C08K5/1345C08K5/526C08L23/30C08K3/24

Inventor 应国军

Owner 余姚市楷瑞电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com