High pressure gas filling process

A high-pressure gas filling technology, which is applied to the equipment loaded into the pressure vessel, the installation device of the container structure, gas/liquid distribution and storage, etc., can solve the problems of short life of the sealing ring, leakage, large pressure difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below through specific implementations:

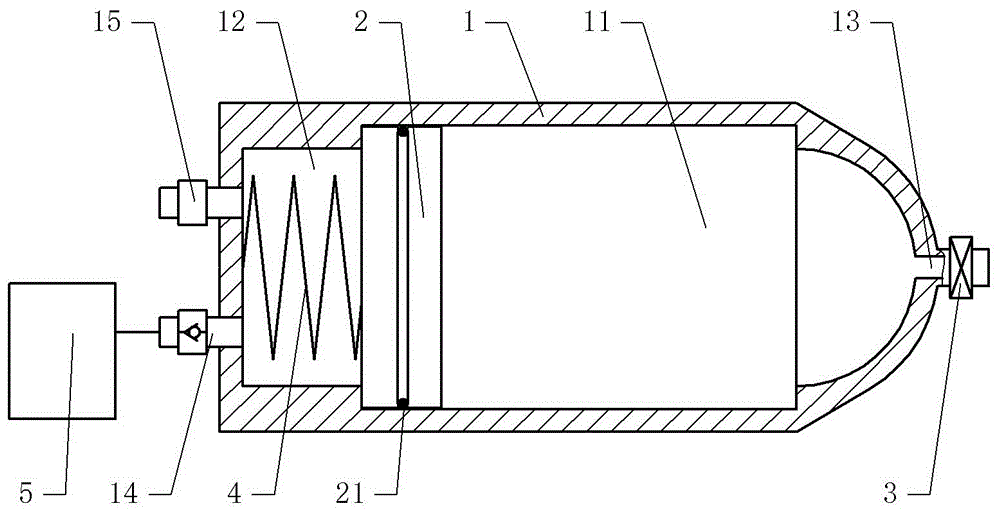

[0029] The reference signs in the drawings of the specification include: tank body 1, compressed natural gas tank 11, air tank 12, air outlet 13, one-way air inlet 14, pressure control valve 15, piston 2, sealing ring 21, exhaust valve 3 , Buffer spring 4, air compressor 5.

[0030] The embodiment is basically like figure 1 Shown:

[0031] The high-pressure gas filling process of this embodiment provides a gas storage tank; the gas storage tank includes a tank body 1, a piston 2 arranged in the tank body 1, and the tank body 1 includes a head end and a tail end. The head end is provided with an air outlet 13 and the air outlet 13 is provided with an exhaust valve 3; the end of the tank body 1 is provided with a pressure control valve 15 and a one-way air inlet 14, and the one-way air inlet 14 is connected to an air compressor 5. Between the piston 2 and the head end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com