CIP (Clean in Place) cleaning method for dairy production line

A cleaning equipment and pickling technology, which is applied in the direction of dairy products, other dairy products, applications, etc., can solve the problems of long cycle cleaning time and poor pertinence, and achieve the effect of increasing the washing time, good pre-rinsing effect, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

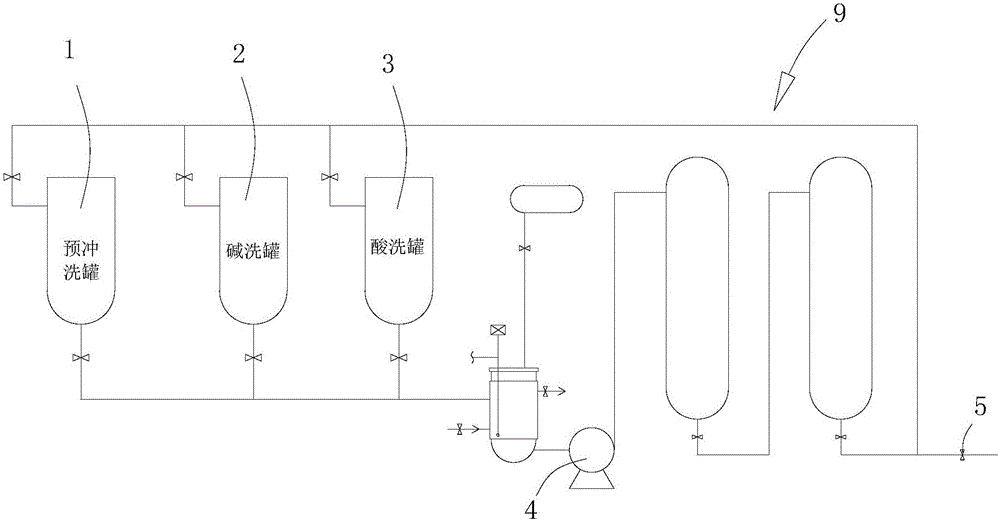

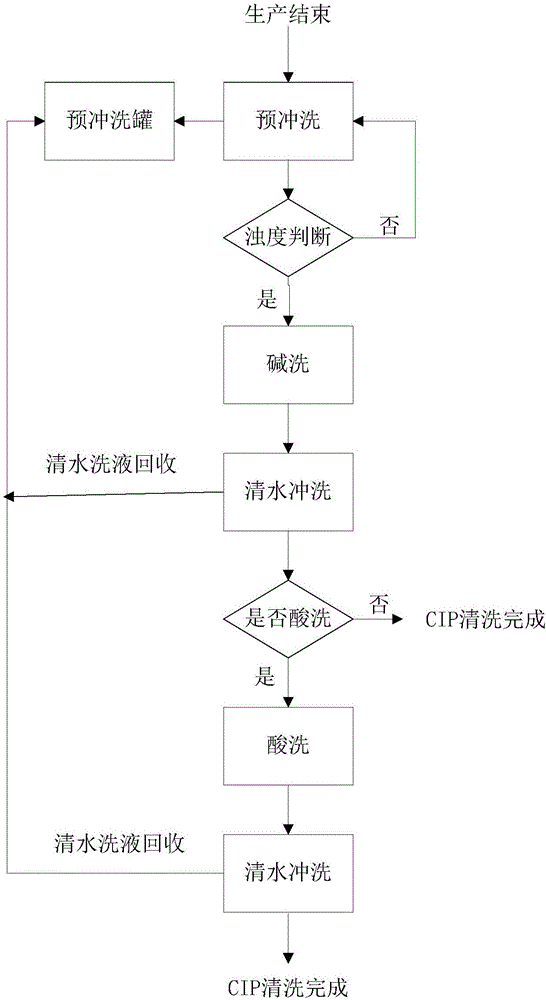

[0027] In the fresh milk No. X canning workshop, the CIP cleaning method technique of the present invention is implemented on the production line A, and the process flow is as follows figure 2 As shown, pickling is not carried out after alkaline cleaning. The specific description is as follows: applications such as figure 1 In the shown CIP cleaning equipment system, after the canned production work on Monday, the CIP cleaning equipment is turned on, and the solution in the pre-rinsing tank 1 is used to pre-wash the equipment 9 on the production line in sequence, and the pre-rinsing solution is exhausted at the end of the valve. 5 Discharge into the waste water tank, observe the turbidity of the pre-flush solution at the discharge outlet, and stop the pre-flush when the solution is not obviously turbid. Then, start the alkaline cleaning process in the CIP cleaning equipment, and use the 2% alkaline solution in the alkaline cleaning tank 2 to perform alkaline cleaning on the ...

Embodiment 2

[0031] Similar to Example 1, on the unified production line, after finishing the canned production on Wednesday, the production line is cleaned by CIP, and the pre-rinsing and alkali cleaning steps described in Example 1 are completed first, and then the CIP cleaning program is adjusted so that the CIP cleaning The 1.8% nitric acid solution in the pickling tank in the equipment enters the pipeline of the CIP flushing equipment and is circulated for 30 minutes. After completion, clean water is used for final flushing (final flushing) of the filling equipment, and the circulation line of CIP flushing is set so that the flushing liquid is circulated back to the pre-rinsing tank or the return tank. Improve the sanitation of tanking lines by preventing the growth of alkali-resistant microorganisms through regular pickling every Wednesday.

[0032] Preferably, after the pickling is completed, the concentration of the nitric acid solution in the pickling tank is adjusted, and repleni...

Embodiment 3

[0034] In the fresh milk canning workshop X of the new factory, adjust the CIP cleaning procedure of the filling machine part on the production line A. Realization includes steps such as pre-rinsing, alkali washing, intermediate washing, pickling, and final washing. The water for the pre-flushing in the control comes from the recovery water tank, and the water for the final flushing comes from the clean water tank. In the process of pre-flushing, the flushing water is not recycled and discharged directly. When the water in the recovery water tank is insufficient, the water in the clean water tank is used for flushing. Experimental research adjusts the CIP data of the filling machine, optimizes the pre-flush time, and then tracks and verifies the optimized pre-flush parameters to ensure the cleaning effect of the filling machine. Finally, the verified optimized parameters were confirmed, and the pre-flushing of the filling machine was performed according to this parameter. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com