Exhaust gas processor in coating production process

A waste gas processor and production process technology, applied in the direction of gas treatment, chemical instruments and methods, combined devices, etc., can solve problems such as weak adsorption capacity, air pollution, and inability to effectively remove formaldehyde and other pollutants, and achieve good purification effect, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

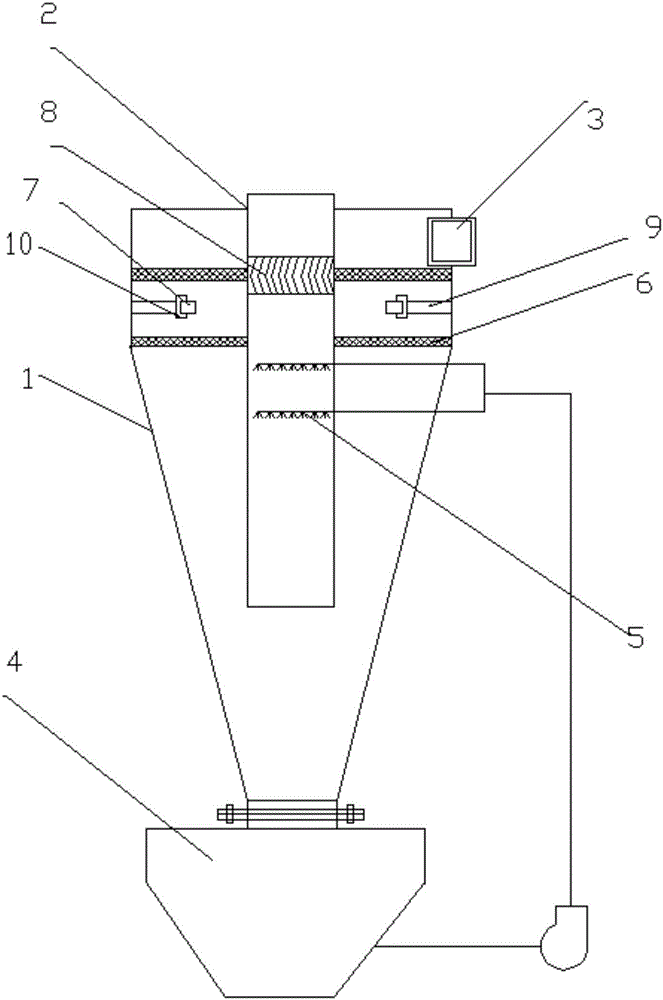

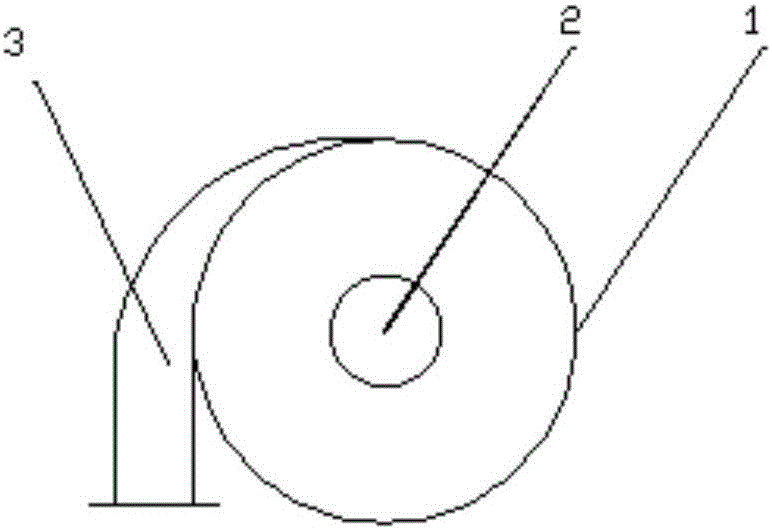

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0013] see figure 1 and figure 2 , an exhaust gas processor in the paint production process, comprising an outer cylinder body 1 and an inner air guide cylinder 2 arranged in the center of the outer cylinder body, an air inlet pipe 3 is arranged in a tangential direction on the outer wall of the upper part of the outer cylinder body, and the upper part of the outer cylinder body is Cylindrical, the lower part is conical with gradually reduced diameter, the inner air guide tube is cylindrical with openings on the top and bottom, and the upper end of the inner air guide tube passes through the top wall of the outer cylinder body and protrudes out ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap