SCR (selective catalytic reduction) denitrification system and operating method thereof

A denitration and flue gas mixing technology, applied in the field of SCR denitration system, can solve the problems of exceeding the standard in local areas, limited effect of adjusting the flue gas flow field distribution, uneven distribution of NH3 at the SCR outlet, etc. Low denitration efficiency and the effect of fly ash removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the specific embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Those skilled in the art should understand that any modification to the specific embodiments of the present invention or equivalent replacement of some technical features without departing from the spirit of the technical solution of the present invention shall be covered by the protection scope of the present invention.

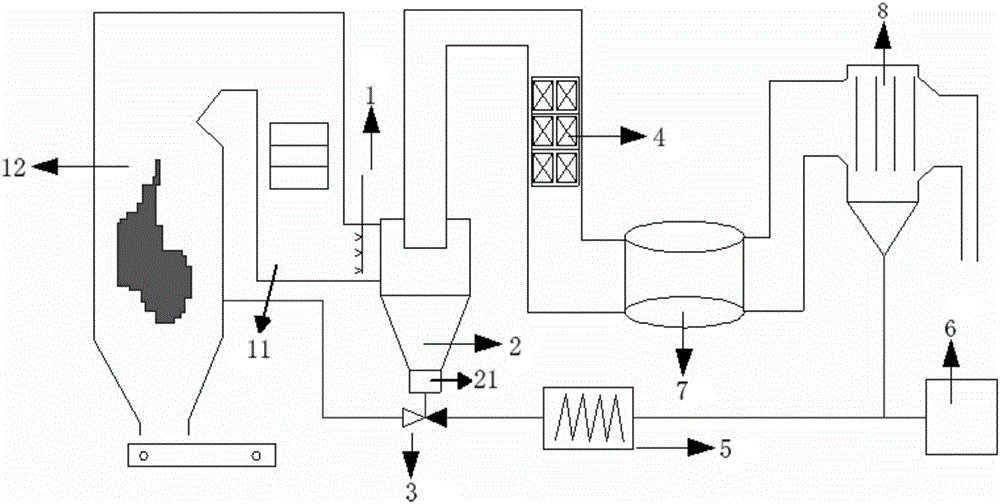

[0031] figure 1 It is a schematic structural diagram of an SCR denitrification system provided in this embodiment, as figure 1 As shown, an SCR denitrification system provided by the present invention includes: an ammonia injection grid (1), a cyclone smoke mixer (2) and a two-way heat exchange valve (3). The cyclone type flue gas mixer (2) is arranged on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com