Size mixing equipment for preparing malt syrup based on real-time temperature regulation and control

A technology of maltose syrup and real-time temperature, which is applied to mixers with rotating stirring devices, dissolvers, mixers, etc., can solve the problems of unfavorable material mixing process, insufficient heat exchange, poor temperature control stability, etc., and achieve the control effect Good, high quality pulping, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

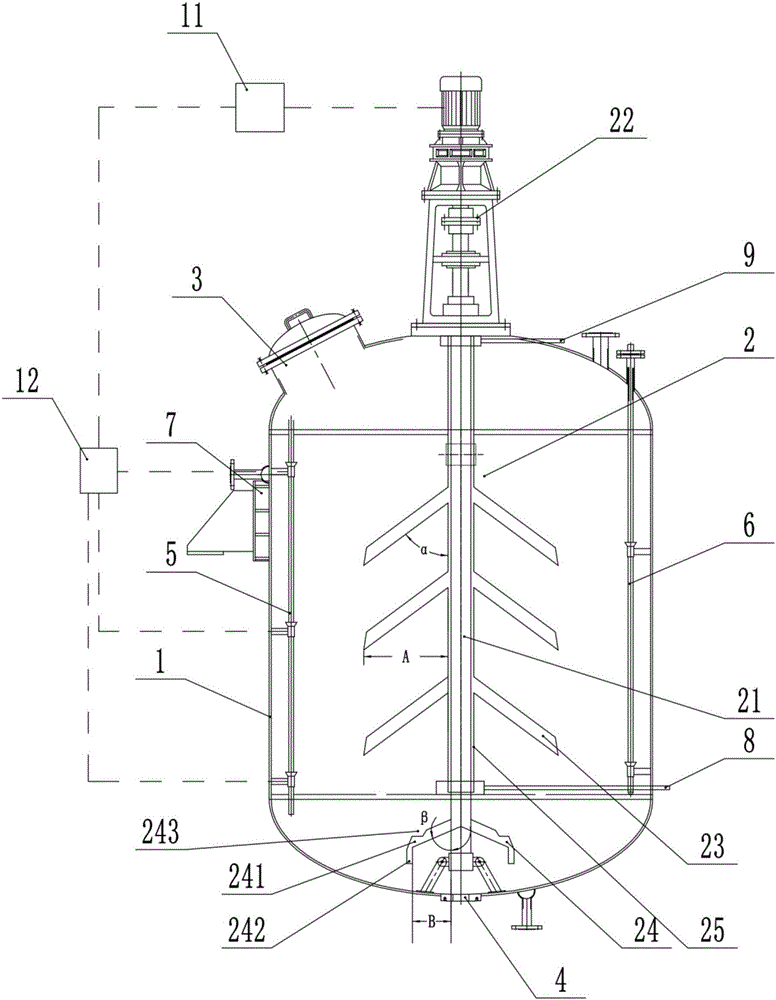

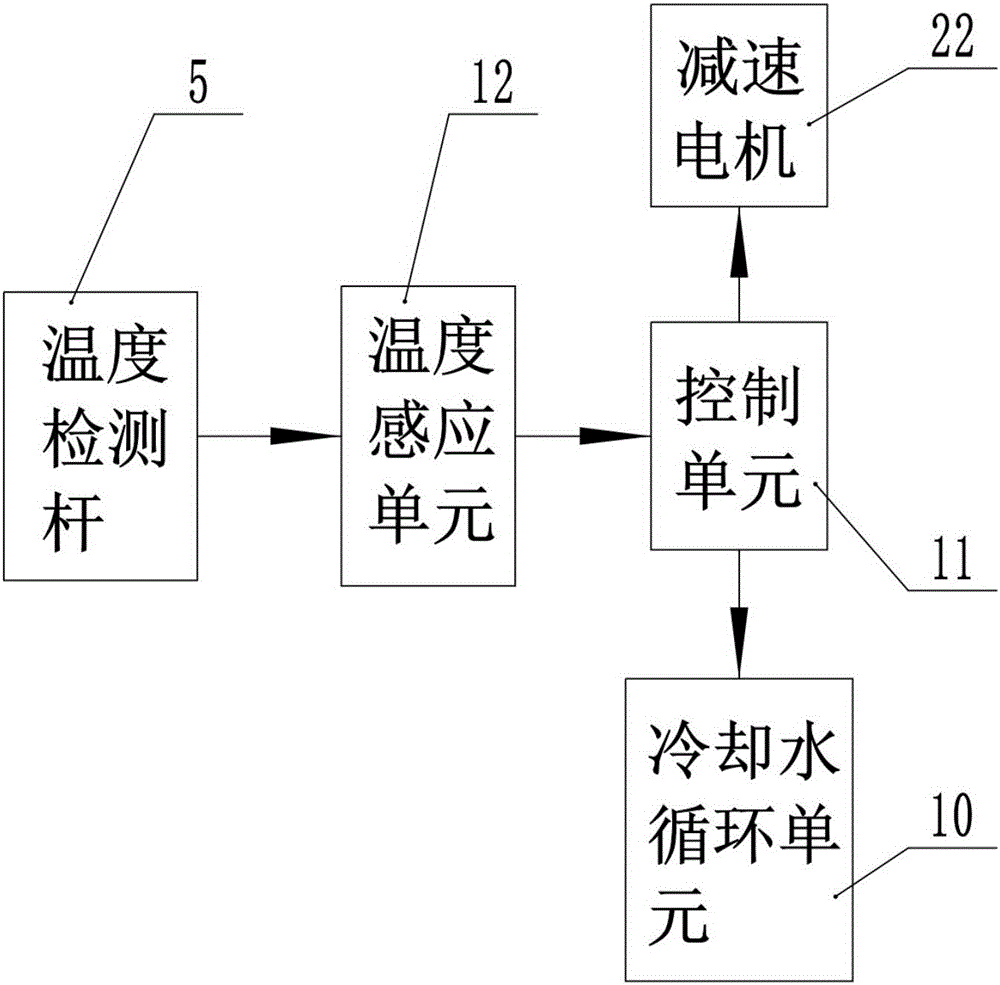

[0017] Embodiment 1: as figure 1 , figure 2 As shown, the maltose syrup preparation equipment based on real-time temperature control in this embodiment includes a tank body 1 and a stirring assembly 2 installed in the tank body 1. The tank body 1 is provided with an upper inlet 3 and a bottom outlet 4. The stirring assembly 2 includes a stirring shaft 21 that is installed in the center of the tank body 1 and coincides with the central axis of the tank body 1, a geared motor 22 that drives the stirring shaft 21 and is placed on the outside of the top of the tank body 1, and the stirring shaft 21 is provided with There is a middle stirring blade 23 located in the middle of the inner cavity of the tank body 1 and a bottom stirring blade 24 located at the bottom of the inner cavity of the tank body 1. The middle stirring blade 23 is sleeved on the stirring shaft 21 by means of a bushing 25, and the bushing 25 and the tank body 1 The middle mixing blade 23 is in the shape of a ho...

Embodiment 2

[0020] Embodiment 2: As a further improvement of the above embodiment 1, such as figure 1 As shown, the middle stirring blade 23 includes multiple layers spaced up and down, and is symmetrically located on both radial sides of the stirring shaft 21; the bottom stirring blade 24 is a single-layer structure, symmetrically arranged on both radial sides of the stirring shaft 21; The included angle α between the stirring blade 23 and the stirring shaft 21 is smaller than the included angle β between the bottom stirring blade 24 and the stirring shaft 21 .

[0021] The mixing blades 23 in the middle are arranged in multiple layers, stirring layer by layer from bottom to top, so as to realize efficient and high-quality pulp mixing. Wherein, the included angle α between the middle part stirring blade 23 and the stirring shaft 21 is smaller than the included angle β between the bottom stirring blade 24 and the stirring shaft 21, the purpose of setting like this is, because the resistan...

Embodiment 3

[0022] Embodiment 3: As a further improvement of Embodiment 1, such as figure 1 As shown, the temperature detection rod 5 is provided with a plurality of temperature detection points arranged up and down, and the temperature detection points are connected with the temperature sensing unit 12 . Due to the high height of the tank body 1, multiple temperature detection points are used to avoid inaccurate detection due to the temperature difference between the upper and lower sides, and the temperature detection reliability is higher.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap