Engine assembly line and assembly method thereof

An assembly line and engine technology, applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing engine production costs, increasing production line construction costs, unfavorable long-term mass production, etc., to reduce consumption time and reduce construction Cost, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

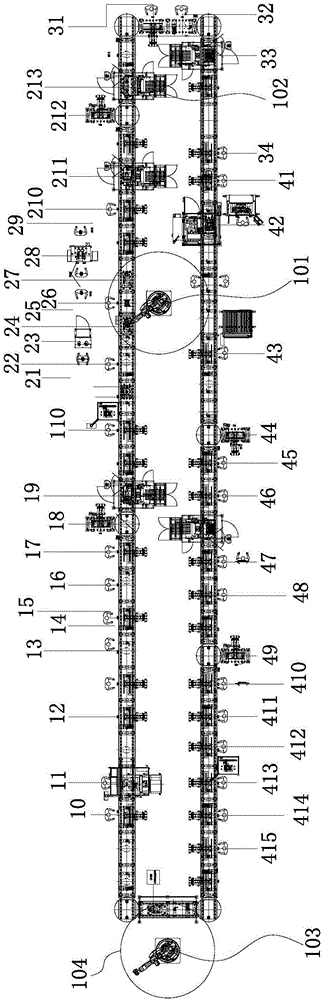

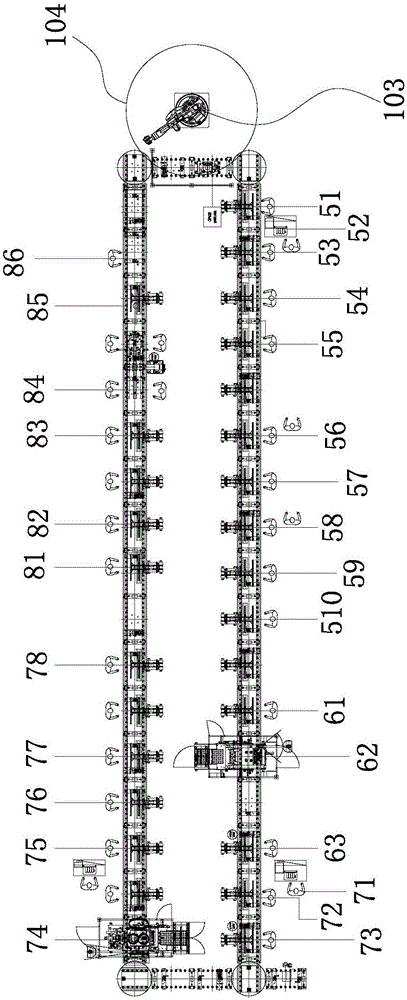

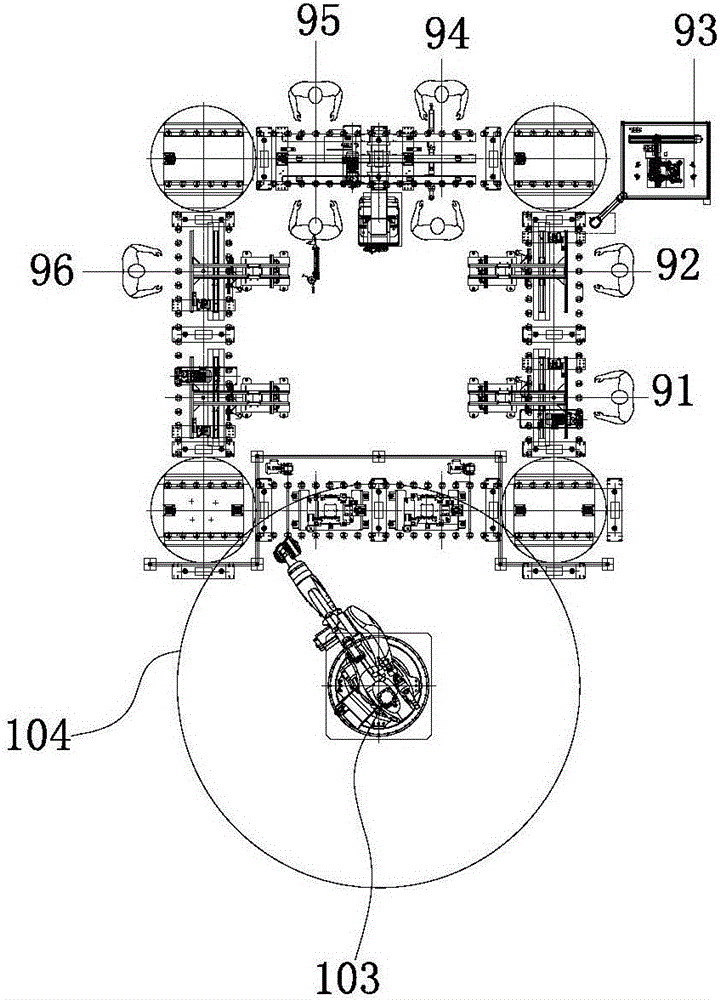

[0029]An engine assembly line, including an internal assembly line, an external assembly line, and an oil pan assembly line, each of which includes a closed-loop conveying line; the internal assembly line mainly includes a conveying direction along its conveying line The cylinder block inspection line section, the piston connecting rod installation section, the cylinder head installation section, the camshaft and tappet installation section are arranged in sequence, and the piston connecting rod installation section is provided with a turning robot 101 for turning over the engine cylinder block The exterior assembly line mainly includes the cylinder head cover installation section, the engine leak test section, and the intake and exhaust pipe installation section which are arranged in sequence along the delivery direction of the delivery line; the oil pan assembly line mainly includes the installation section along the delivery line The filter installation station 91, the oil p...

Embodiment 2

[0039] A method of assembling an engine using the engine assembly line, comprising the following steps:

[0040] Step 1: Hoist the engine cylinder block from the front end of the cylinder block inspection line section of the internal installation line. At this time, the top of the engine cylinder block faces downward, and then perform marking, main cover removal, main upper tile installation, main tile oil dripping, and crankshaft in sequence. Sending wheel installation, crankshaft on-line pre-installation, main shaft bearing bearing installation and thrust plate installation, main cover installation and bolt pre-tightening, main cover bolt tightening and axial clearance measurement, rear oil seal bracket gluing and installation operations, among which the main After the cover installation and bolt pre-tightening operations are completed, the installed parts need to be inspected, and the parts that are not installed up to the standard shall be manually repaired;

[0041] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com