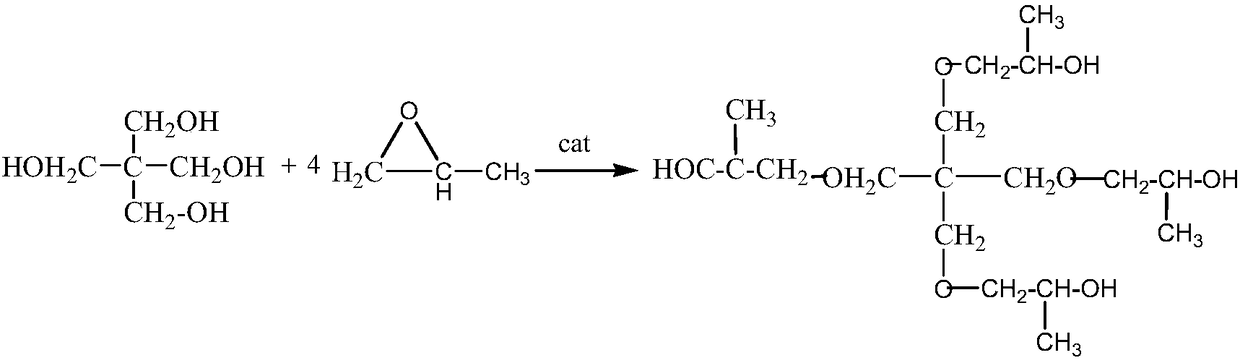

A kind of preparation method of hydroxypropylated pentaerythritol ether

A technology of hydroxypropylated pentaerythritol ether and pentaerythritol, which is applied in the field of organic compound synthesis, can solve the problems of affecting product quality and application performance, failing to synthesize narrow-distribution polyether, and affecting product performance, so as to shorten the production process and improve the overall activity , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of the reaction kettle before the implementation of this embodiment: wash the 2.5L high-pressure stirred glass reaction kettle with distilled water several times until it is clean, dry the reaction kettle, and cool it to normal temperature for later use.

[0035] Example 1

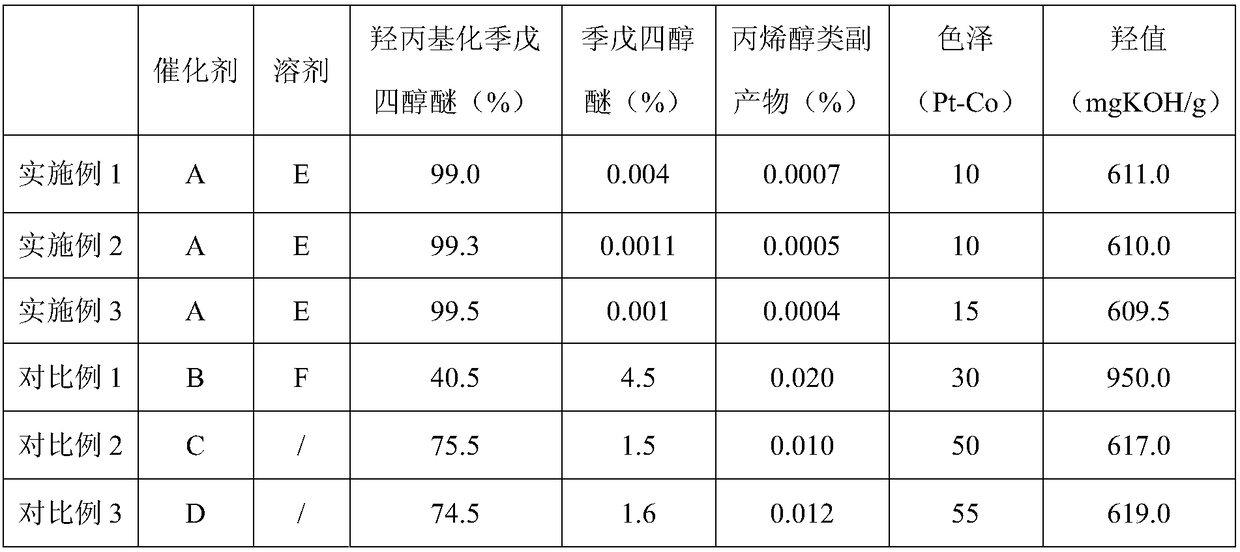

[0036] In reactor, add pentaerythritol 408g, three (4-methoxyphenyl) phosphine 1.0g, solvent hydroxypropylated pentaerythritol ether 350g, vacuumize with vacuum pump, adopt N 2 Replace the air in the reactor. After three replacements, turn off the vacuum and start to heat up to 110°C under the vacuum degree ≥ -0.096MPa. After the material has no obvious solid material, continue to add 710g of propylene oxide, and control the reaction temperature at 110-125°C , The pressure in the reactor is -0.02 ~ 0.4Mpa. After the addition, keep warm and continue the reaction until the pressure no longer drops. The entire reaction addition time is about 3h. After the reaction is completed, the tem...

Embodiment 2

[0038] In reactor, add pentaerythritol 408g, three (4-methoxyphenyl) phosphine 0.8g, solvent hydroxypropylated pentaerythritol ether 410g, vacuumize with vacuum pump, adopt N 2 Replace the air in the reactor. After three replacements, turn off the vacuum and start to heat up to 100°C under the vacuum degree ≥ -0.096MPa. After the material has no obvious solid material, continue to add 780g of propylene oxide, and control the reaction temperature at 110-125°C , The pressure in the reactor is -0.02 ~ 0.4Mpa. After the addition, keep warm and continue the reaction until the pressure no longer drops. The entire reaction addition time is about 3.5h. After the reaction is completed, the temperature is lowered to about 70°C and vacuum degassing is adopted, and the vacuum ≥ -0.098MPa is kept for 10 minutes, and then the material is discharged to obtain the finished product. The product is analyzed by liquid chromatography: the content of propylene alcohol by-products is 0.0005%, the c...

Embodiment 3

[0040] In reactor, add pentaerythritol 408g, three (4-methoxyphenyl) phosphine 1.6g, solvent hydroxypropylated pentaerythritol ether 470g, vacuumize with vacuum pump, adopt N 2 Replace the air in the reactor. After three replacements, turn off the vacuum and start to heat up to 100°C under the vacuum degree ≥ -0.096MPa. After the material has no obvious solid material, continue to add 750g of propylene oxide, and control the reaction temperature at 110-125°C , The pressure in the reactor is -0.02 ~ 0.35Mpa. After the addition, keep warm and continue the reaction until the pressure no longer drops. The entire reaction addition time is about 3.0h. After the reaction is completed, the temperature is lowered to about 70°C and vacuum degassing is adopted, and the vacuum ≥ -0.098MPa is kept for 10 minutes, and then the material is discharged to obtain the finished product. The product is analyzed by liquid chromatography: the content of propylene alcohol by-products is 0.0004%, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com