Asphalt modifying agent and modified asphalt

A technology of asphalt modifier and modified asphalt, which is applied in the direction of building components, building insulation materials, buildings, etc. It can solve the problems of unsatisfactory asphalt performance improvement, asphalt performance limitation, and difficulty in dispersion modification, etc., and achieves obvious modification effect , small dosage, good effect of changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

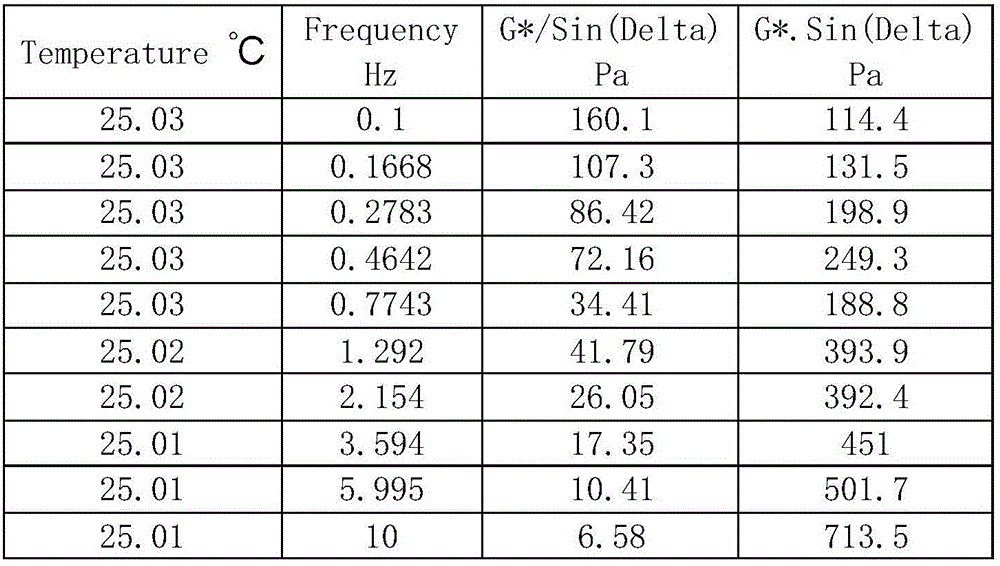

[0023] Add 1 gram of vinyl POSS into 10 grams of trichlorethylene, fully dissolve, add 0.02 grams of KH550, 99 grams of asphalt, stir well, and carry out polymerization and solvent volatilization at 110 ° C to obtain POSS modified asphalt, the POSS modified Asphalt dynamic shear modulus table 2:

[0024] Table 2

[0025]

[0026]

[0027] From the above results, it can be seen that in the modified asphalt of the present invention, when the amount of POSS containing organic functional groups is small, the anti-rutting factor decreases, the elastic modulus decreases significantly, and the anti-fatigue performance is greatly improved.

Embodiment 2

[0029] Add 2.5 grams of vinyl POSS into 10 grams of trichlorethylene, fully dissolve, add 0.03 grams of KH550, 97 grams of asphalt, stir well, and carry out polymerization and solvent volatilization at 120 ° C to obtain POSS modified asphalt, the POSS modified The dynamic shear modulus of asphalt is shown in Table 3:

[0030] table 3

[0031]

[0032] From the above results, it can be seen that when the content of POSS containing organic functional groups increases, the elastic modulus also increases, but it is lower than the increase in anti-rutting factor, and the performance of asphalt is significantly modified.

Embodiment 3

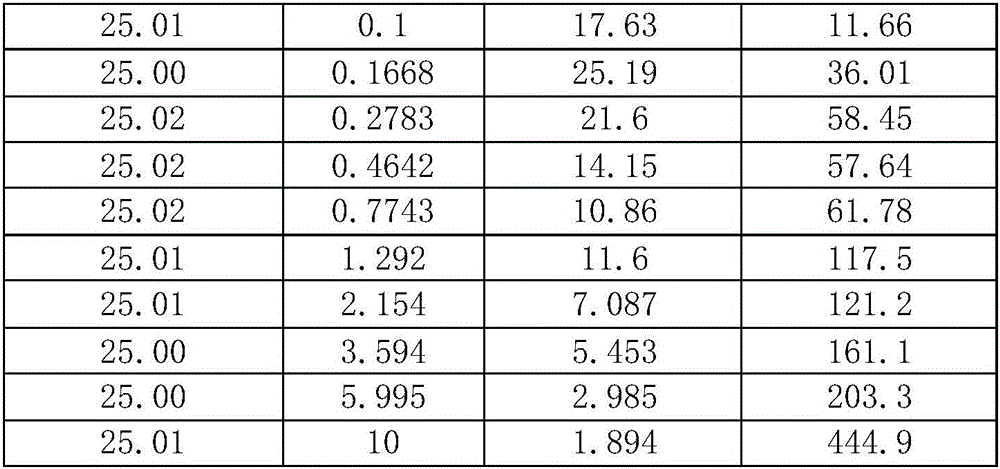

[0034] Add 3 grams of vinyl POSS into 10 grams of trichlorethylene, fully dissolve, add 0.03 grams of KH550, 97 grams of asphalt, stir evenly, and carry out polymerization and solvent volatilization at 120 ° C to obtain POSS modified asphalt.

[0035] The dynamic shear modulus of 3% POSS modified asphalt is shown in Table 4:

[0036] Table 4

[0037]

[0038] From the above results, it can be seen that when the content of POSS containing organic functional groups increases, the elastic modulus also increases, but it is lower than the increase in anti-rutting factor, and the performance of asphalt is significantly modified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com