Sunflower head corrosion inhibitor extract and method for preparing metal acid-pickling solution using the same

A sunflower plate and metal acid technology, applied in the field of sunflower plate corrosion inhibitor extract and its preparation of metal pickling solution, can solve the problems of low economic value, environmental pollution, resource waste, etc., and achieve simple production process and water solubility Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

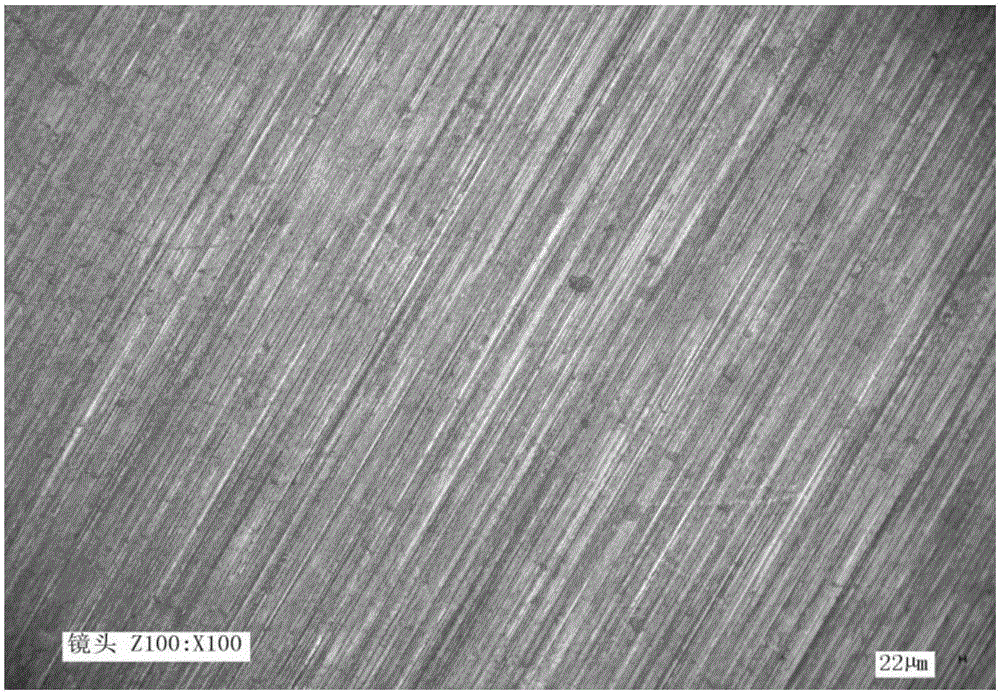

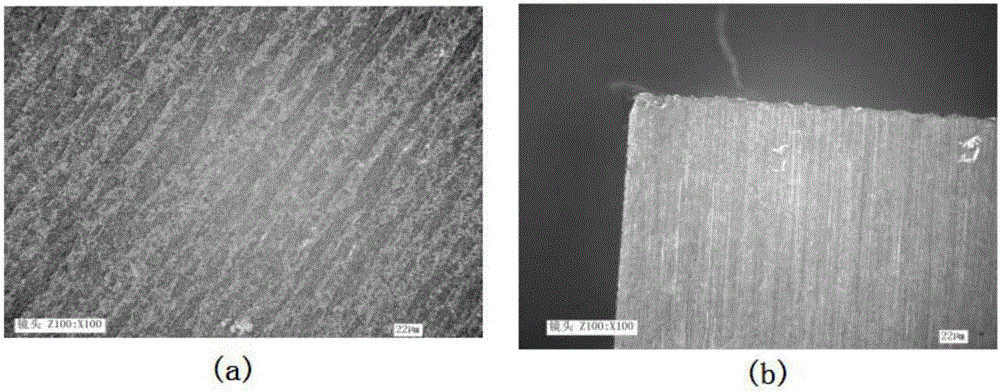

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing a metal pickling solution with sunflower disc extract as a corrosion inhibitor. The preparation method uses sunflower disc extract as a metal pickling corrosion inhibitor, a hydrochloric acid solution as a metal pickling reagent, and then The metal pickling reagent is added to the sunflower disk extract to prepare. Specifically, the sunflower disk is used as a raw material. After heat treatment, the sunflower disk corrosion inhibitor extract is prepared, and then hydrochloric acid solution is used as the metal pickling reagent to add the sunflower disk to the sunflower disk. In the etching agent extraction solution, the metal pickling solution is obtained.

[0034] The method for preparing a metal pickling solution includes:

[0035] S1: Prepare sunflower disc corrosion inhibitor extract and use it as metal pickling corrosion inhibitor;

[0036] S2: Prepare a 1mol / L hydrochloric acid solution and add it as a metal pickling reagent...

Embodiment 1

[0050] Prepare 100mL pickling solution according to sunflower plate extract and 1mol / L HCl 1:9(V / V) at a temperature of 20℃, and immerse the 45# carbon steel to be cleaned in the pickling solution for 48h. Its corrosion inhibition efficiency is 94.39%.

Embodiment 2

[0052] Prepare 100mL pickling solution according to the sunflower disc extract and 1mol / L HCl 2:8 (V / V) at a temperature of 20℃, and immerse the 45# carbon steel to be cleaned in the pickling solution for 48h. Its corrosion inhibition efficiency is 97.26%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com