Assembled type steel framework prefabricated concrete floor slab structure

A prefabricated concrete and steel frame technology, applied in the direction of floors, structural elements, building components, etc., can solve the problems of large amount of concrete pouring, required labor, urban environmental impact, etc., to reduce project cost, improve construction quality, reduce The effect of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

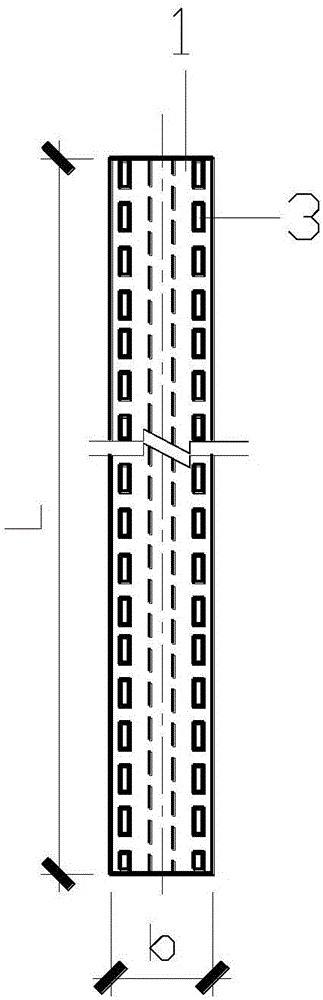

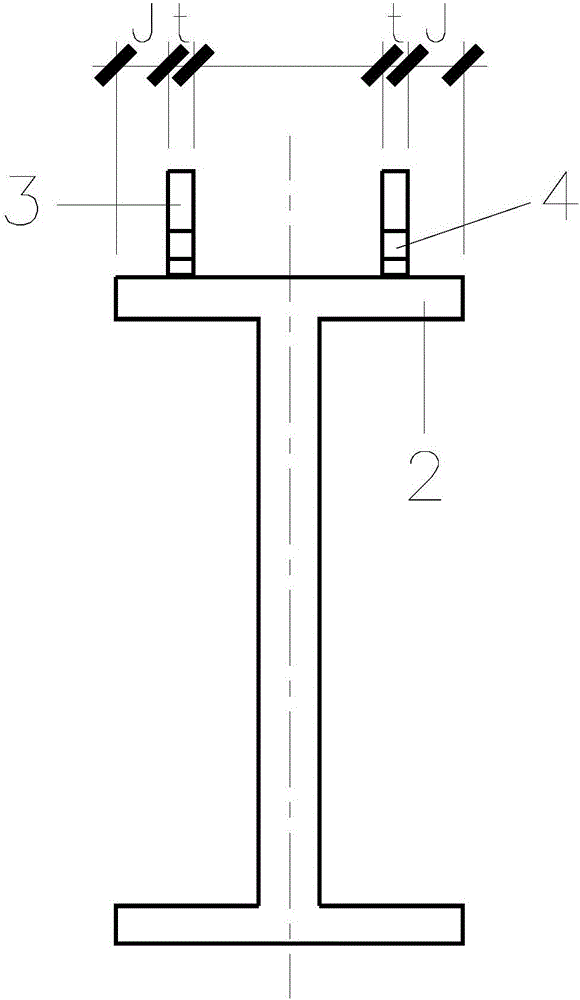

[0025] refer to Figure 1 to Figure 5 , an assembled steel frame prefabricated concrete floor structure, comprising a steel frame and a precast concrete floor, the steel frame including steel columns and steel beams 1, the precast concrete floor is located above the steel beams 1 and installed through connectors on steel beam 1;

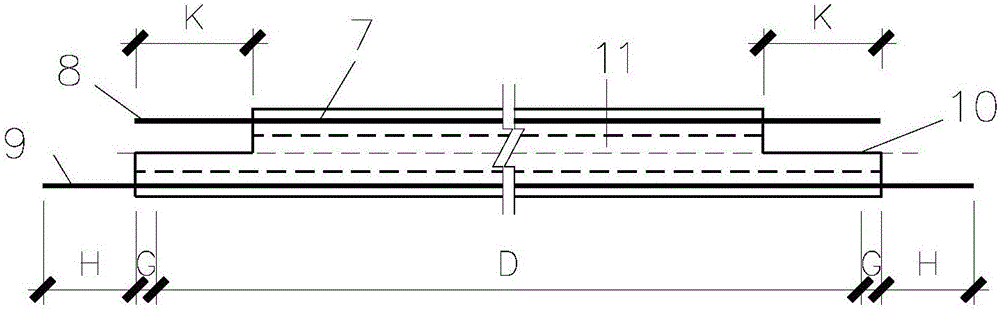

[0026] The prefabricated concrete floor is a prestressed hollow floor.

[0027] Further, the upper part of the prestressed hollow floor is provided with a steel bar 7, the middle part of the prestressed hollow floor is provided with a hollow through hole 11 along the span direction, and the lower part of the prestressed hollow floor is pierced with steel bars at the bottom , the surface steel bars 7 are arranged horizontally along the span direction and both ends are provided with overhanging sections 8, and the bottom reinforcement bars ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com