Tunnel Strengthening Treatment Method and Supporting Structure Based on Dissolution Cavity Location

A technology of support structure and tunnel, applied in the direction of tunnel, tunnel lining, earthwork drilling and mining, etc., can solve the inconsistency between strengthening support structure and treatment method, safety evaluation of karst tunnel and results without comprehensive consideration of karst cavity in different positions and other problems, to achieve the effect of solving construction and safe operation, fast construction, and comprehensive consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment is a tunnel strengthening treatment method based on the location of the dissolved cavity, and the method includes the following steps:

[0044] S1. Determine the location and shape of the cave in the karst area, as well as the shortest distance L between the cave and the tunnel. Specifically, according to the engineering geological survey report, geological radar detection was carried out on the site to determine the location, shape, scale and extension direction of the cave in the karst area. At the top, the dissolution chamber is 5.5m high, 4.5m in length, and about 8m in width. The direction of the dissolution chamber is perpendicular to the direction of the tunnel. There is no connection between the karst area and the tunnel and the distance between the karst area and the tunnel is 10.8m, that is, the L between the left karst cavity and the tunnel is 10.8m.

[0045] S2. Determine the safe thickness H of the tunnel karst area, establish a finite elem...

Embodiment 2

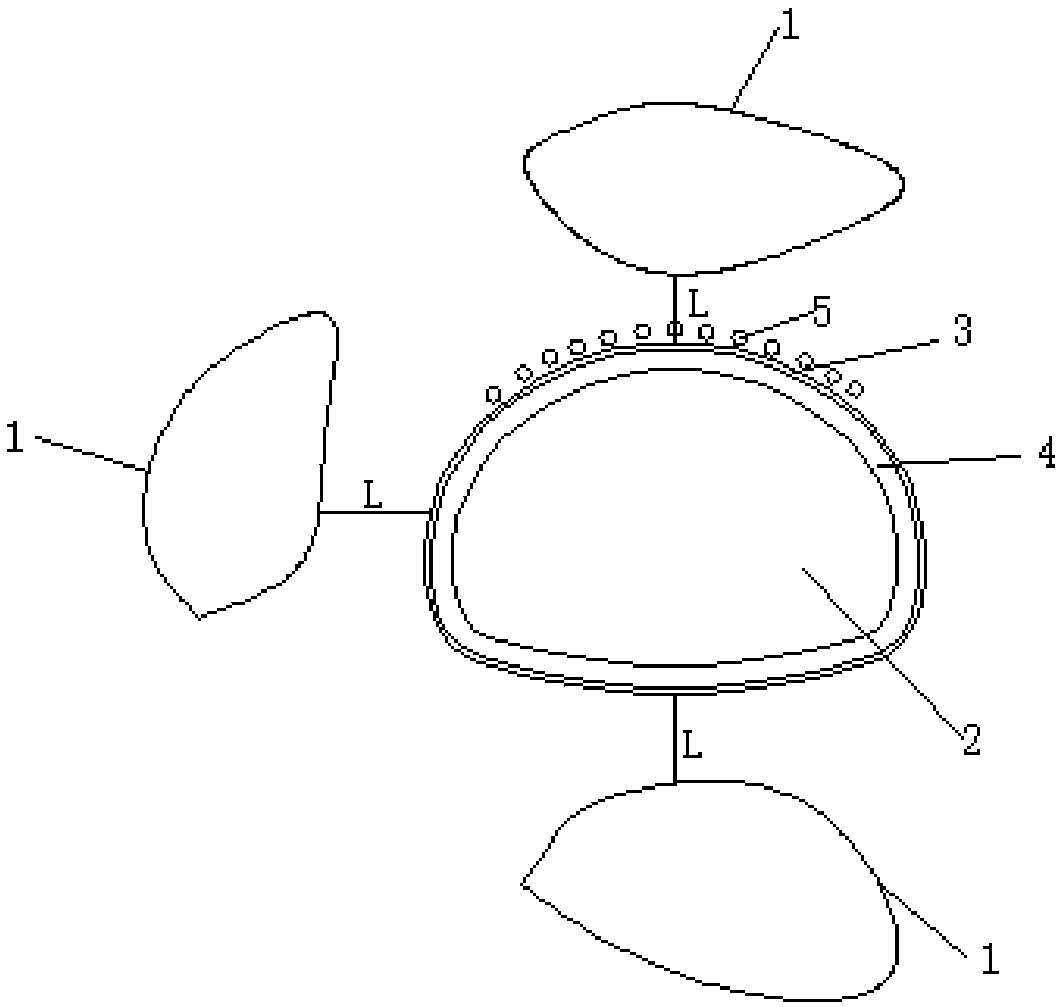

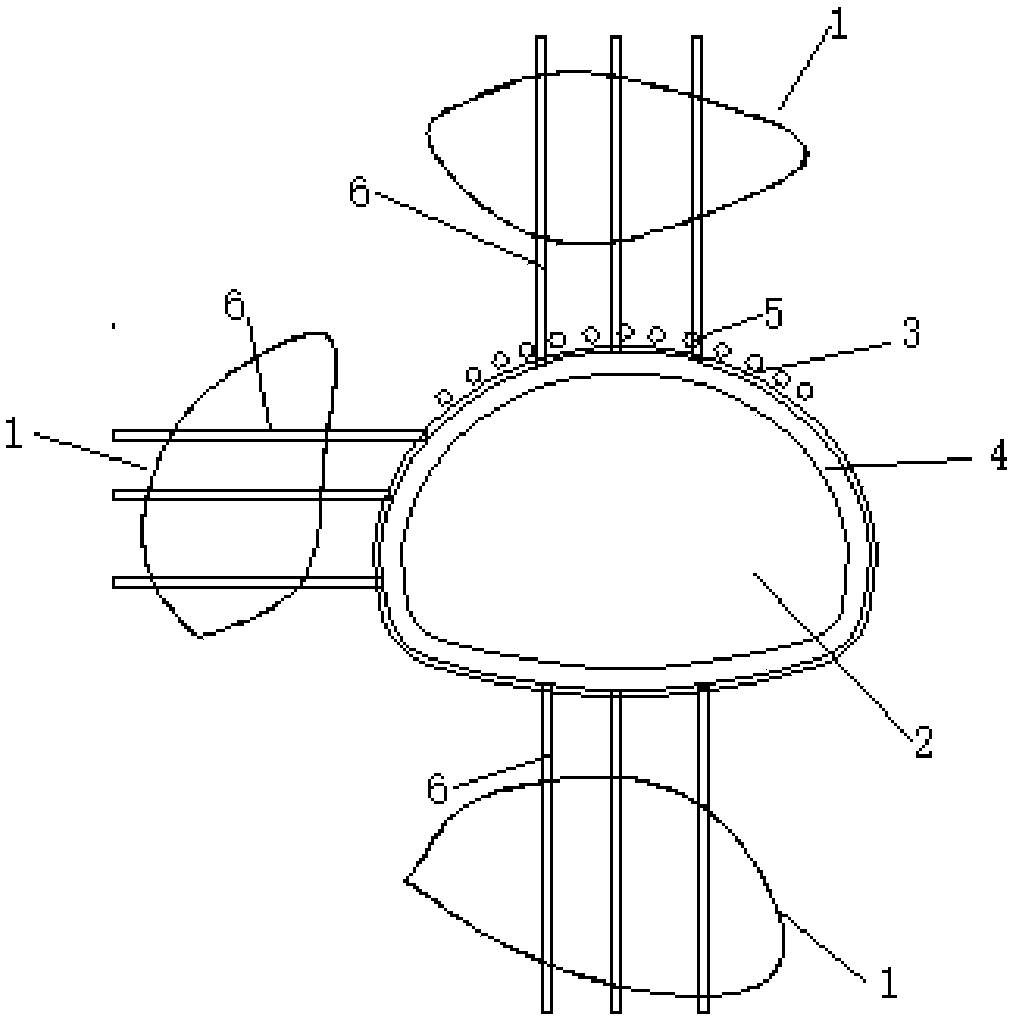

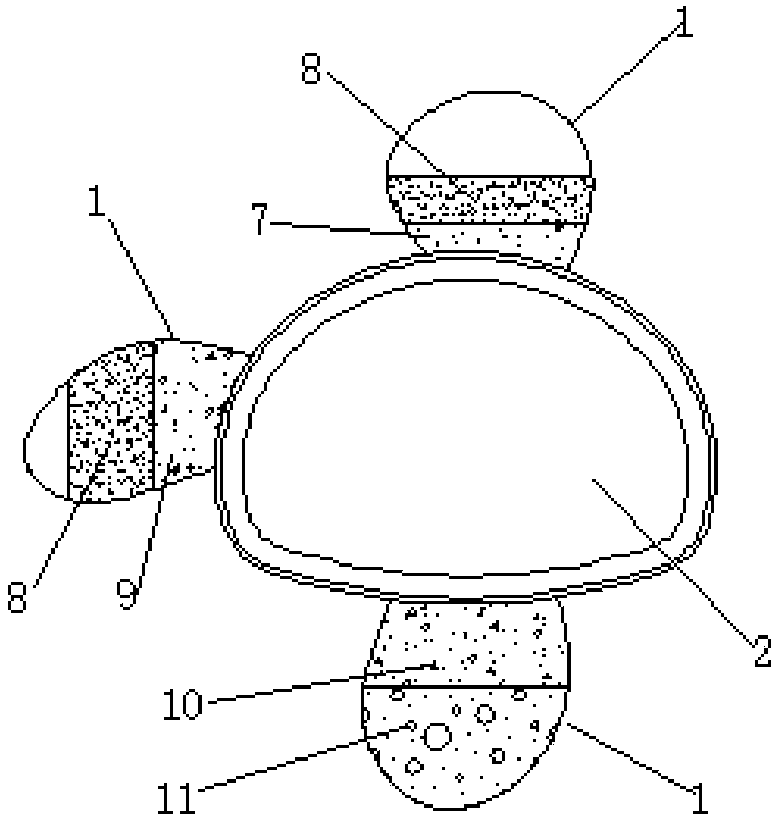

[0068] This embodiment is a tunnel support structure based on the position of the dissolution cavity, including the initial support 3 located in the circumferential direction of the tunnel 2, the secondary lining 4 and the advance support 5, and also includes a double-layer structure located between the tunnel 2 and the dissolution cavity 1 Backfill composite structures.

[0069] The double-layer backfill composite structure includes a double-layer backfill composite structure at the top of the tunnel, a double-layer backfill composite structure in the middle of the tunnel, and a double-layer backfill composite structure at the bottom of the tunnel, wherein:

[0070] The double-layer backfill composite structure at the top of the tunnel includes an anti-seepage concrete arch 7 arranged above the excavation surface of the tunnel 2 and a gravel backfill buffer layer 8 arranged directly above the anti-seepage concrete arch 7;

[0071] The double-layer backfill composite structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com