Method for determining stress-induced martensitic transformation critical point of shape memory alloy composite damping material

A technology of composite damping material and martensitic phase transformation, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of scarce equipment, complicated operation, expensive testing costs, etc., and achieve the effect of high accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

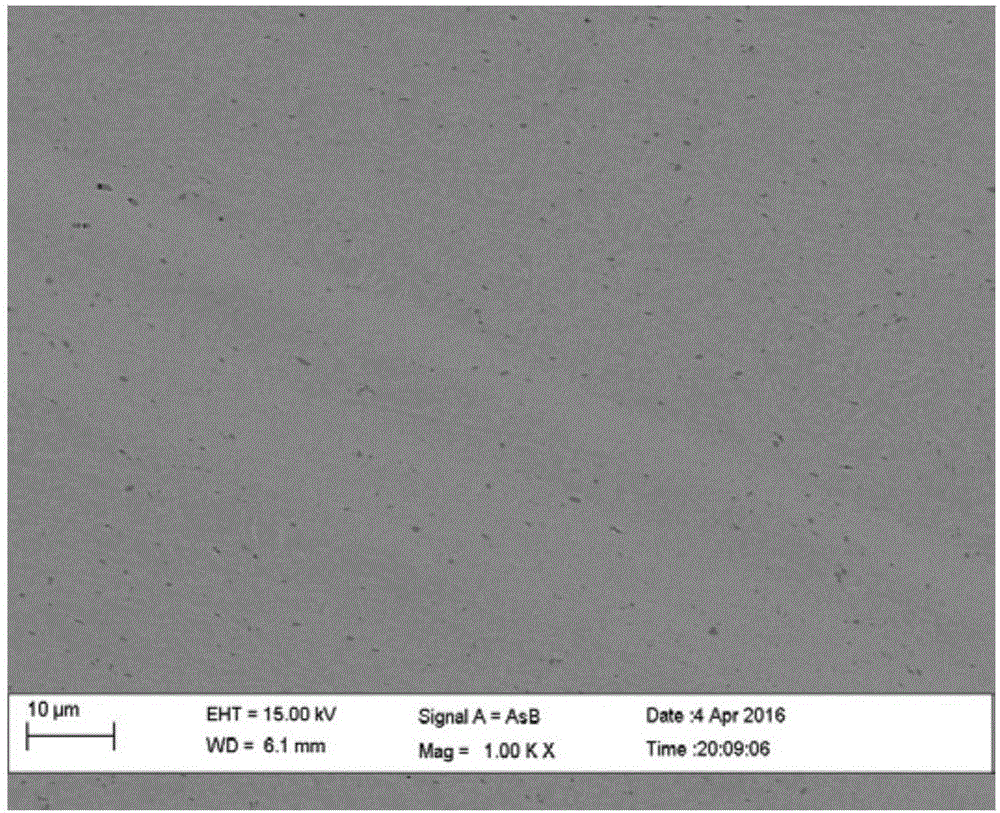

[0034] The composition is Ni 50 Ti 50Take the dense shape memory alloy damping material as an example, that is, the alloy contains 50% Ni element and 50% Ti element at an atomic ratio. The scanning electron microscope photo of the sample is as follows figure 1 As shown, the surface is flat and consists of a single NiTi phase.

[0035] The method for determining the stress-induced martensitic transformation critical point of a shape memory alloy composite damping material comprises the following steps:

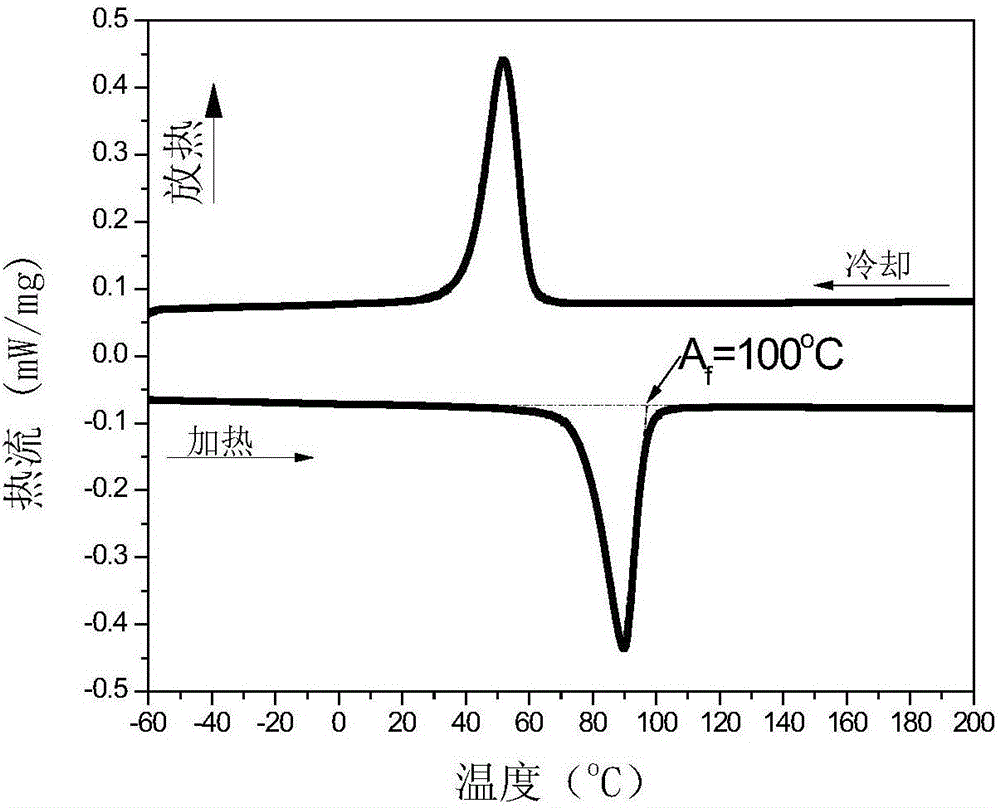

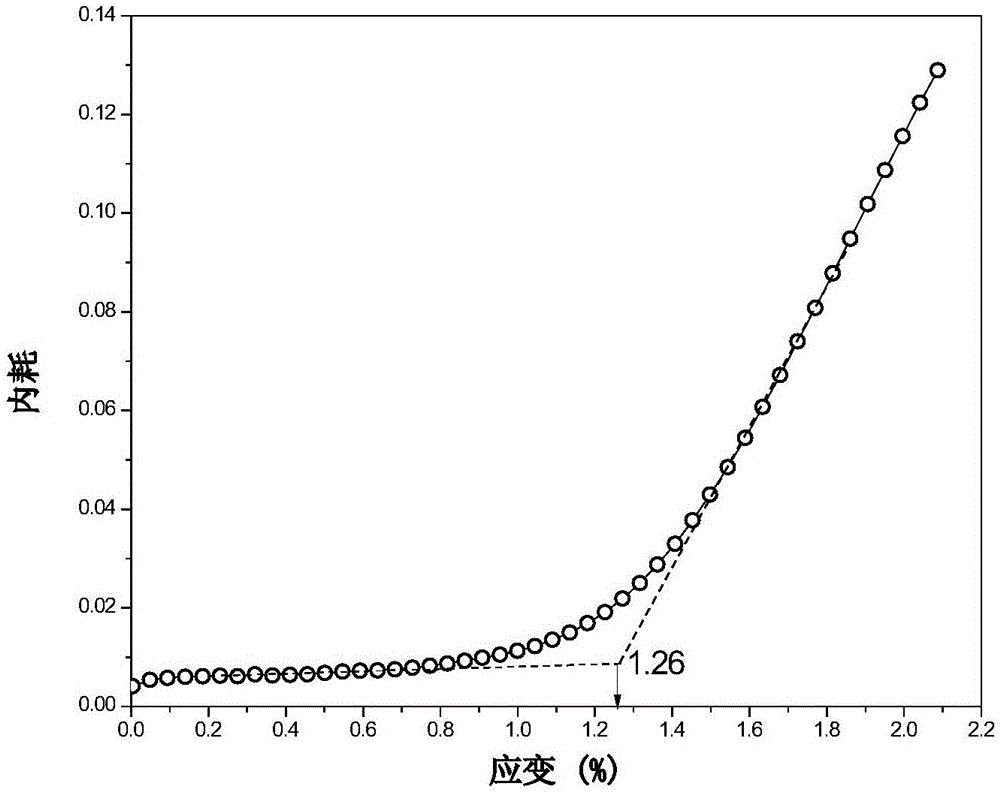

[0036] (1) The dense Ni was measured by differential thermal scanning thermal analysis method 50 Ti 50 The DSC curve of the shape memory alloy sample, such as figure 2 As shown, the heating or cooling rate used is 5°C / min, and the test temperature range is -60 to 200°C. First, the sample is heated to 200°C for 2 minutes, and then cooled to -60°C at a rate of 5°C / min. Obtain the cooling curve, i.e. figure 2 The curve in the middle and upper part, then stay for 2 minutes,...

Embodiment 2

[0041] The composition is Ni 46 Ti 54 Take the dense shape memory alloy composite damping material as an example, that is, the alloy contains 46% Ni element and 54% Ti element in atomic ratio, and the microstructure of the sample is composed of two phases, semi-network and granular Ti 2 Ni phase, distributed in the NiTi matrix phase, such as Figure 4 As shown, the dark phase is Ti 2 Ni phase, light color is NiTi phase.

[0042] The method for determining the stress-induced martensitic transformation critical point of a shape memory alloy composite damping material comprises the following steps:

[0043] (1) The DSC curve of the dense NiTi shape memory alloy sample is measured by differential thermal scanning thermal analysis method, such as Figure 5 As shown, the heating or cooling rate used is 10°C / min, and the test temperature range is -60 to 200°C. First, the sample is heated to 200°C for 2 minutes, and then cooled to -60°C at a rate of 10°C / min. Obtain the cooling c...

Embodiment 3

[0048] The composition is Ni 46 Ti 54 Take the porous shape memory alloy composite damping material as an example, that is, the alloy contains 46% Ni element and 54% Ti element in atomic ratio. The sample is a porous material with a porosity of 37% and a pore size of about 200 μm, as shown in Fig. It is porous Ni in this embodiment 46 Ti 54 The metallographic photograph of shape memory alloy composite damping material; Fig. 7 b is the present embodiment porous Ni 46 Ti 54 Scanning electron micrograph of shape memory alloy composite damping material; as shown in Figure 7a, its microstructure is composed of two phases, granular Ti 2 Ni phase, distributed in the NiTi matrix phase, as shown in Figure 7b, the dark phase is Ti 2 The Ni phase, the light color is the NiTi phase, indicating that there are many pore surfaces in the sample, and the interface between the second phase and the matrix is increased, which all help to increase the damping performance of the memory alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com