optical cable for vehicle

A technology for optical cables and vehicles, applied in the field of communication optical cables, to achieve the effect of small size, excellent environmental performance and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

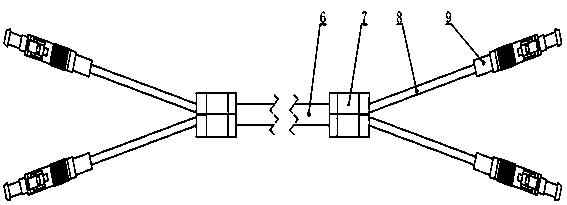

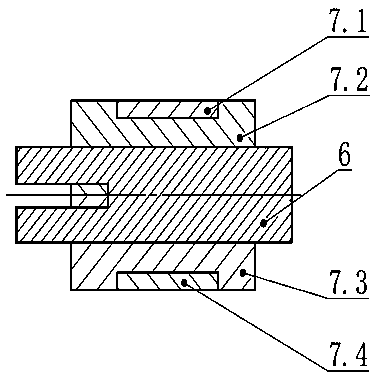

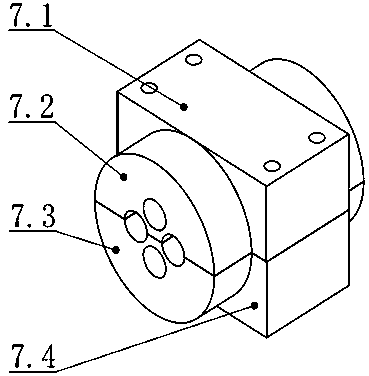

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] Including a main cable 6 and a branch cable 8, the main cable 6 includes a skeleton 4, four skeleton grooves are evenly distributed on the periphery of the skeleton, an optical fiber 3 is laid in the skeleton groove, and an optical fiber is laid in each skeleton groove, the skeleton The center is equipped with a non-metallic central reinforcement 5, the non-metallic reinforcement is a reinforced plastic rod, the skeleton is covered with a water-blocking tape 2, the water-blocking tape is covered with an outer sheath 1, and the outer sheath Made of oil-resistant polymer materials, such as TPU, TPE and other sheathing materials. One end or two ends of the main cable are installed with a split cable protector 7, one side of the split cable protector is connected to the main cable, and the other side leads to a branch cable 8, and the branch cable inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com