Reverse type electric-control liquid-crystal light adjusting film and preparation method thereof

A liquid crystal dimming film, liquid crystal technology, applied in nonlinear optics, optics, instruments, etc., can solve the problems of poor adhesion, poor film stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Step 1: The proportioning ratio of selected liquid crystals, polymerizable monomers, initiators, and spacer particles is listed in Table 2. Mix the components in Table 2 according to the ratio, and stir at room temperature to form an isotropic liquid, and mix well. The total mass of the mixture is 100 mg.

[0052] Table 2. The proportioning of each material used in embodiment 1

[0053] name Proportion / % Positive liquid crystal SLC1717 69.0 polymerizable monomer 30.0 Initiator 0.5 20um spacer particles 0.5

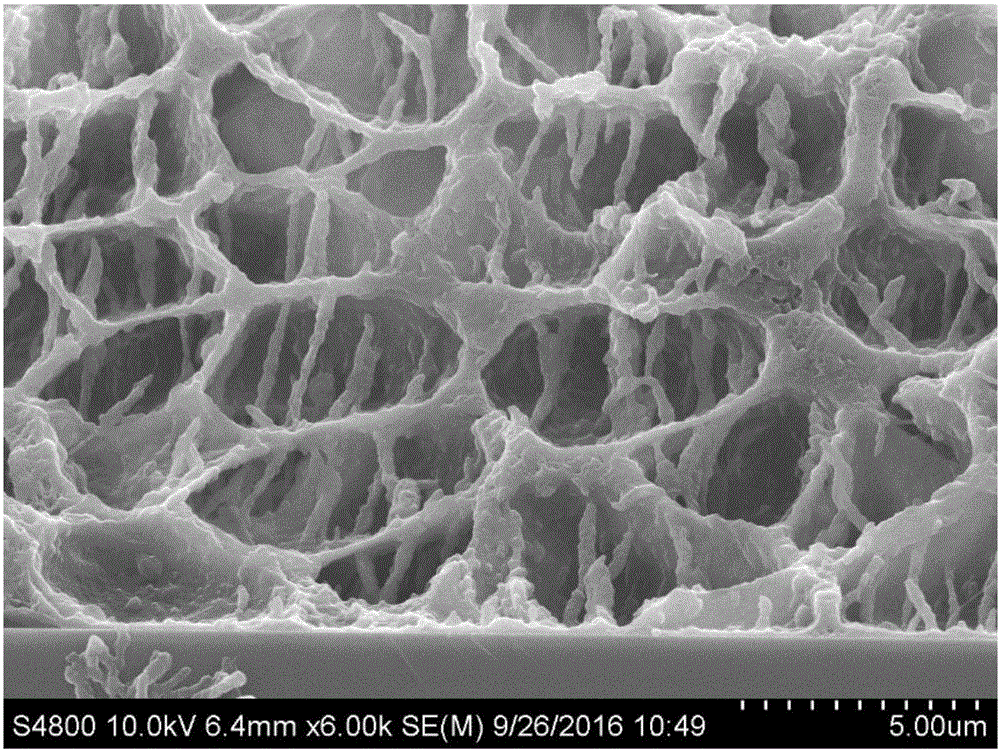

[0054] Step 2: apply the above solution on the middle of two plastic films with a size of 50mm*50mm coated with indium tin oxide (ITO) transparent conductive film, and use a roller to press evenly to form a film. The film is irradiated by ultraviolet light with a wavelength of 365nm at room temperature, and the ultraviolet light intensity is 0.5mw / cm 2 , the illumination time is 90s, and then the film is made into an upper ...

Embodiment 2

[0058] Step 1: The selected liquid crystals, polymerizable monomers, initiators, and spacer particles are listed in Table 3. Mix the components in Table 3 according to the ratio, and stir at room temperature to form an isotropic liquid, and mix well. The total mass of the mixture is 100mg.

[0059] Table 3. The proportioning of each material used in embodiment 2

[0060] name Proportion / % Positive liquid crystal E7 69.0 polymerizable monomer 30.0 Initiator 0.5 20um spacer particles 0.5

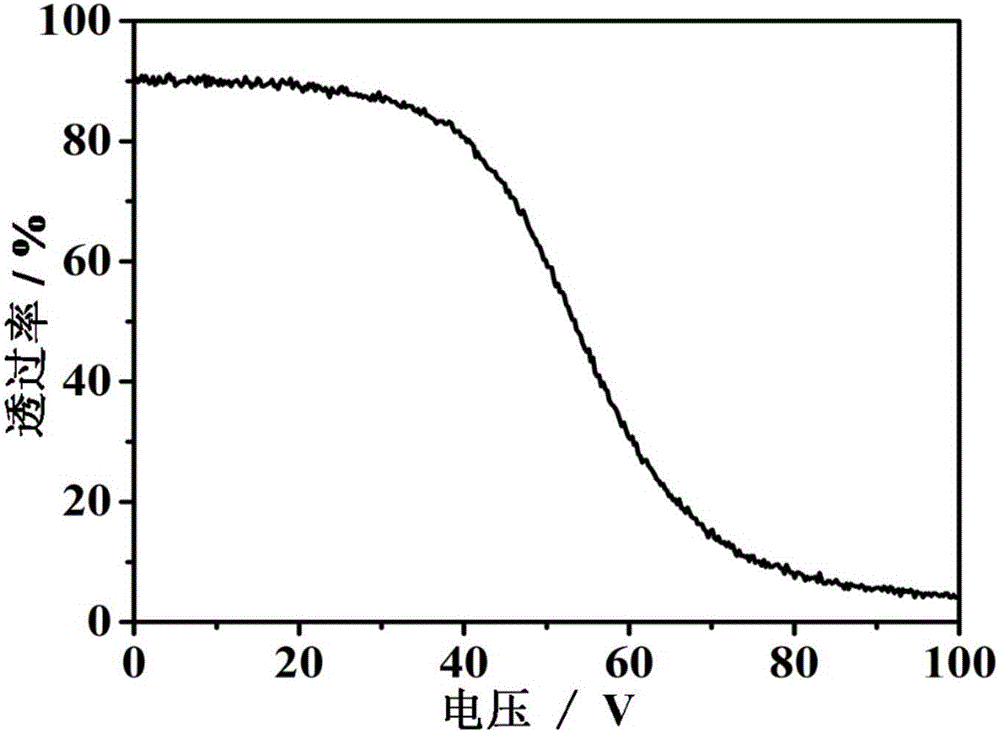

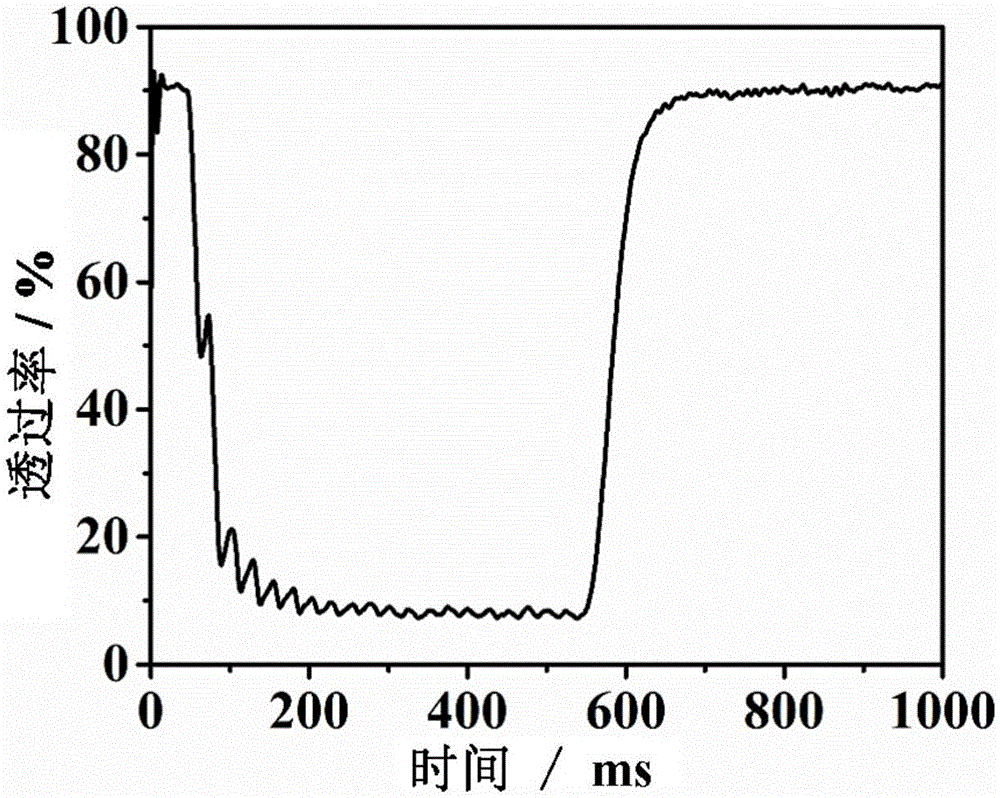

[0061] Step 2: apply the above solution on the middle of two plastic films with a size of 50mm*50mm coated with indium tin oxide (ITO) transparent conductive film, and use a roller to press evenly to form a film. The film is irradiated by ultraviolet light with a wavelength of 365nm at room temperature, and the ultraviolet light intensity is 0.5mw / cm 2 , the illumination time is 90s, and then the film is made into an upper electrode, a voltage of 50.0...

Embodiment 3

[0065] Step 1: The selected liquid crystals, polymerizable monomers, initiators, and spacer particles are listed in Table 4. Mix the components in Table 4 according to the ratio, and stir at room temperature to form an isotropic liquid, and mix well. The total mass of the mixture is 100mg. The molecular structure and proportioning ratio of each component of the positive liquid crystal with smectic phase to cholesteric phase transition used in this embodiment are shown in Table 4

[0066] Table 4. The proportioning of each material used in embodiment 3

[0067]

[0068]

[0069] Step 2: apply the above solution on the middle of two plastic films with a size of 50mm*50mm coated with indium tin oxide (ITO) transparent conductive film, and use a roller to press evenly to form a film. The film is irradiated by ultraviolet light with a wavelength of 365nm at room temperature, and the ultraviolet light intensity is 0.5mw / cm 2 , the illumination time is 90s, and then the film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com